Production process of EVA (Ethylene Vinyl Acetate) colored solar film

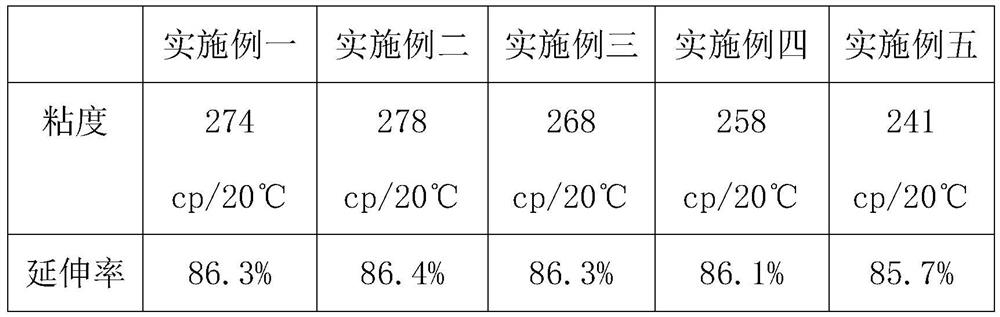

A production process, solar technology, applied in the direction of film/sheet adhesives, adhesives, films/sheets without carriers, etc., which can solve the problems of low degree of material fusion, reduced film strength, and reduced elongation, etc. Achieve the effect of reducing the risk of fracture, increasing elongation and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific embodiments.

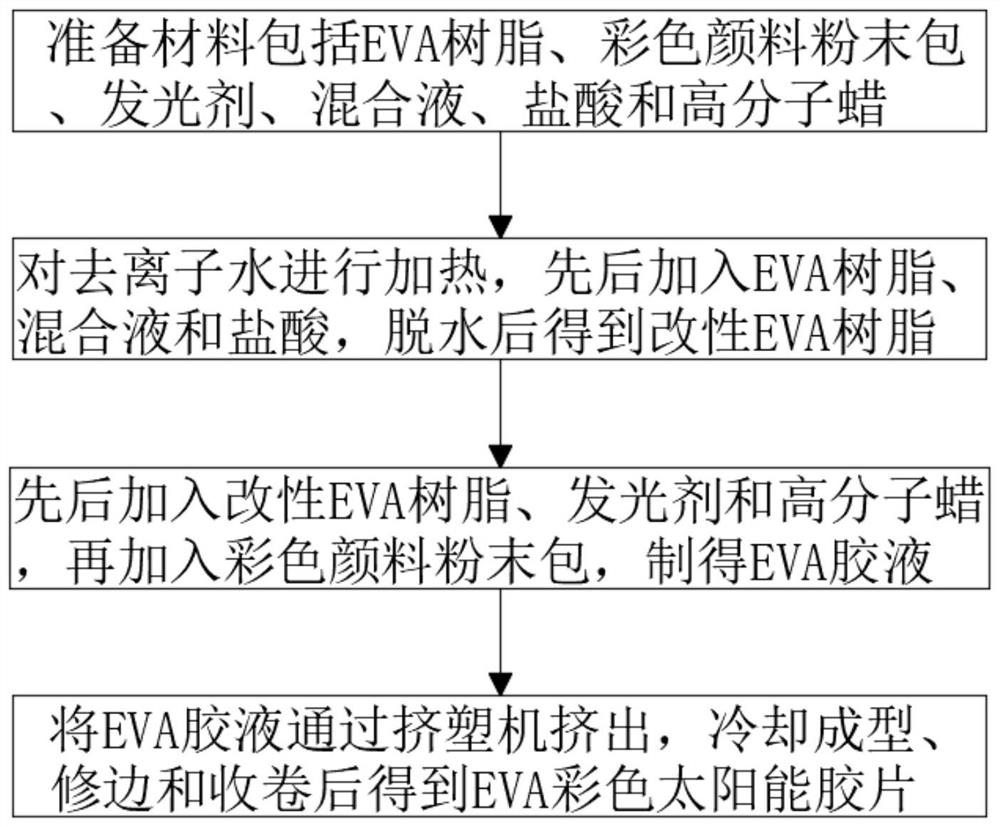

[0023] refer to figure 1 , embodiment one

[0024] A kind of production technology of EVA color solar film is proposed in the present embodiment, comprises the following steps:

[0025] S1: Preparation materials include 100 parts of EVA resin, 4 parts of color pigment powder package, 14 parts of luminescent agent, 82 parts of mixed solution, 81 parts of hydrochloric acid and 61 parts of polymer wax. The luminescent agent contains acid anhydride monomer, Pyrazoline derivatives, nickel dioxide powder, coumarin derivatives and hyaluronic acid, the mixture contains propionaldehyde, butyraldehyde and ethyl acetate, acid anhydride monomers in the luminescent agent, pyrazoline derivatives, dioxide The weight ratio of nickel powder, coumarin derivatives and hyaluronic acid is 3:2.5:2:1.5:1, the preparation method of luminescent agent: acid anhydride monomer, pyrazoline derivative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com