High-power multi-mode broadband rotary joint

A rotary joint, high-power technology, applied in electrical components, circuits, waveguide-type devices, etc., to achieve high power capacity, reduced wear, and wide operating frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

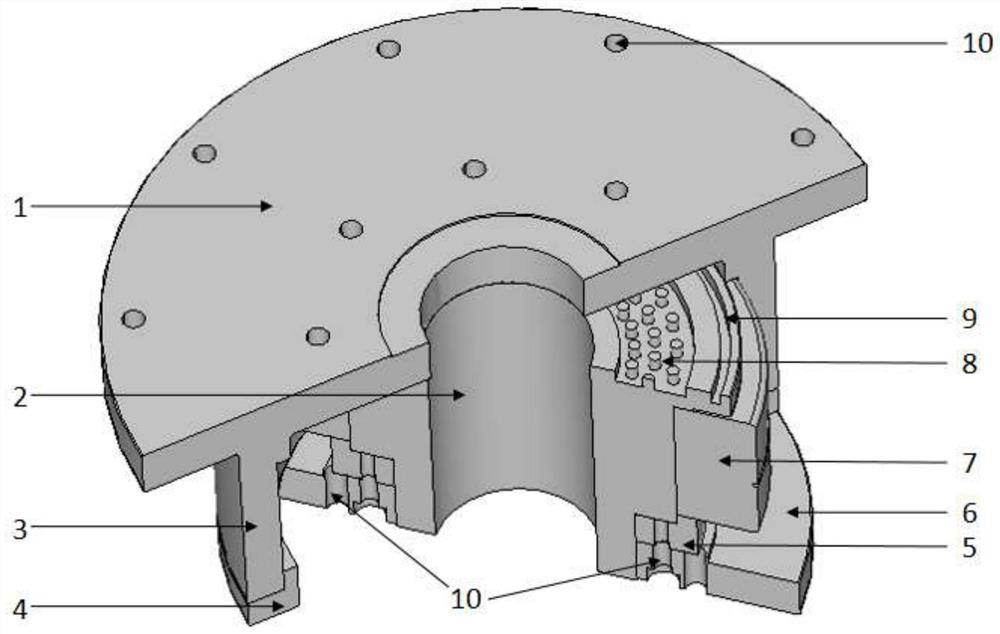

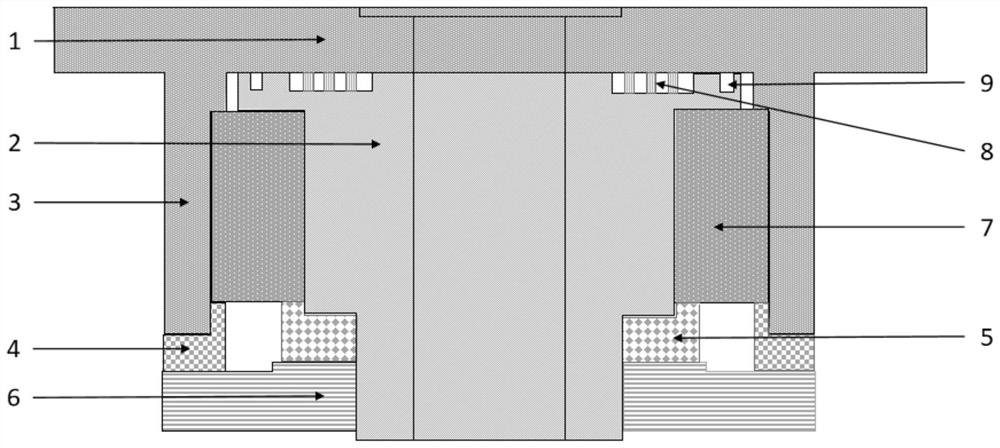

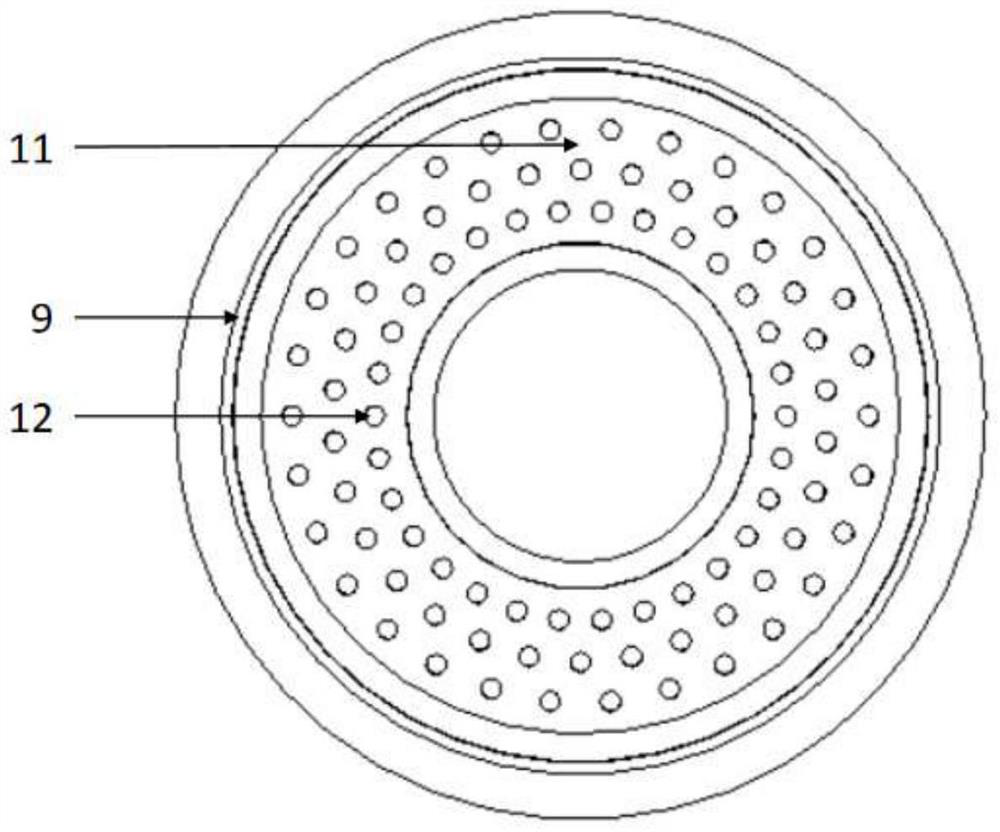

[0033] The specific implementation of the Ku-band non-contact high-power microwave rotary joint will be described below in conjunction with the accompanying drawings to meet the design goals of the Ku-band high-power gyro-traveling wave tube system.

[0034] Such as figure 1 , figure 2 As shown, the high-power multimode broadband rotary joint includes a rotor circular waveguide 1, a stator circular waveguide 2, a gap waveguide choke structure 8, a choke coil structure 9 and a connection structure; the rotor circular waveguide 1 and the stator The circular waveguide 2 is an overmolded circular waveguide with the same caliber and coincident central axis, with a radius of 25 mm, and relative rotation is realized through a bearing structure; the gap waveguide choke structure 8 and the choke coil structure 9 are arranged on the rotor circular waveguide 1 and Adjacent end faces of the stator circular waveguide 2. The distance between the end faces is 0.1 mm, which ensures that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com