Powder for laser 3D printing degradable magnesium alloy bone plate and preparation method

A 3D printing and magnesium alloy technology, which is applied in the field of laser 3D printing, can solve the problems of room temperature forming and poor corrosion resistance, limit the application of magnesium alloys, limit the secondary processing of magnesium alloy plates, etc., achieve a high degree of flexibility, reduce pain and Economical pressure, the effect of overcoming poor forming at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

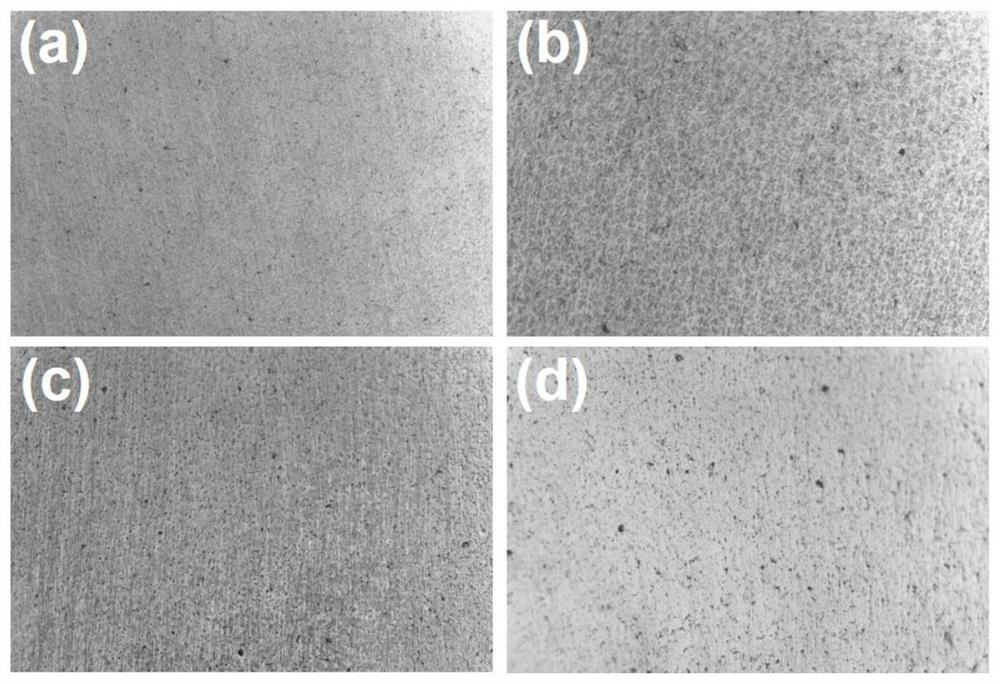

Image

Examples

Embodiment 1

[0056] A kind of powder used for laser 3D printing degradable magnesium alloy bone plate, the powder used for laser 3D printing degradable magnesium alloy bone plate includes Mg powder, Zn powder and Mn powder, the mass fraction of Mg powder is 98.8%; the mass fraction of Zn powder The fraction is 1%; the mass fraction of Mn powder is 0.2%. The purity of Mg powder, Zn powder and Mn powder is ≥99.9%, the particle size is 30-80μm, the oxygen content is ≤100ppm, and the humidity is ≤0.2%.

[0057] A method for laser 3D printing of degradable magnesium alloy bone plates using powder materials used in laser 3D printing degradable magnesium alloy bone plates:

[0058] Step 1, using a CNC wire cutting machine to process a magnesium plate with a purity greater than or equal to 99.9 wt% into a thickness of 2 cm and use it as a substrate;

[0059] Step 2. The surface of the substrate is made of 60 # 、100 # 、240 # 、320 # 、500 # SiC metallographic sandpaper is polished to remove the...

Embodiment 2

[0068] A kind of powder used for laser 3D printing degradable magnesium alloy bone plate, the powder used for laser 3D printing degradable magnesium alloy bone plate includes Mg powder, Zn powder and Mn powder, the mass fraction of Mg powder is 97.8%; the mass fraction of Zn powder The fraction is 2%; the mass fraction of Mn powder is 0.2%. The purity of Mg powder, Zn powder and Mn powder is ≥99.9%, the particle size is 30-80μm, the oxygen content is ≤100ppm, and the humidity is ≤0.2%.

[0069] A method for laser 3D printing of degradable magnesium alloy bone plates using powder materials used in laser 3D printing degradable magnesium alloy bone plates:

[0070] Step 1, using a CNC wire cutting machine to process a magnesium plate with a purity greater than or equal to 99.9 wt% into a thickness of 3 cm and use it as a substrate;

[0071] Step 2. The surface of the substrate is made of 60 # 、100 # 、240 # 、320 # 、500 # SiC metallographic sandpaper is polished to remove the...

Embodiment 3

[0080] A kind of powder used for laser 3D printing degradable magnesium alloy bone plate, the powder used for laser 3D printing degradable magnesium alloy bone plate includes Mg powder, Zn powder and Mn powder, the mass fraction of Mg powder is 95.8%; the mass fraction of Zn powder The fraction is 4%; the mass fraction of Mn powder is 0.2%. The purity of Mg powder, Zn powder and Mn powder is ≥99.9%, the particle size is 30-80μm, the oxygen content is ≤100ppm, and the humidity is ≤0.2%.

[0081] A method for laser 3D printing of degradable magnesium alloy bone plates using powder materials used in laser 3D printing degradable magnesium alloy bone plates:

[0082] Step 1, using a CNC wire cutting machine to process a magnesium plate with a purity greater than or equal to 99.9 wt% into a thickness of 4 cm and use it as a substrate;

[0083] Step 2. The surface of the substrate is made of 60 # 、100 # 、240 # 、320 # 、500 # SiC metallographic sandpaper is polished to remove the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com