Box type building and production and installation method thereof

A box-type, construction technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of common quality problems, cracking and leakage, large water consumption, etc., to achieve high product quality, reduction of construction waste, production fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

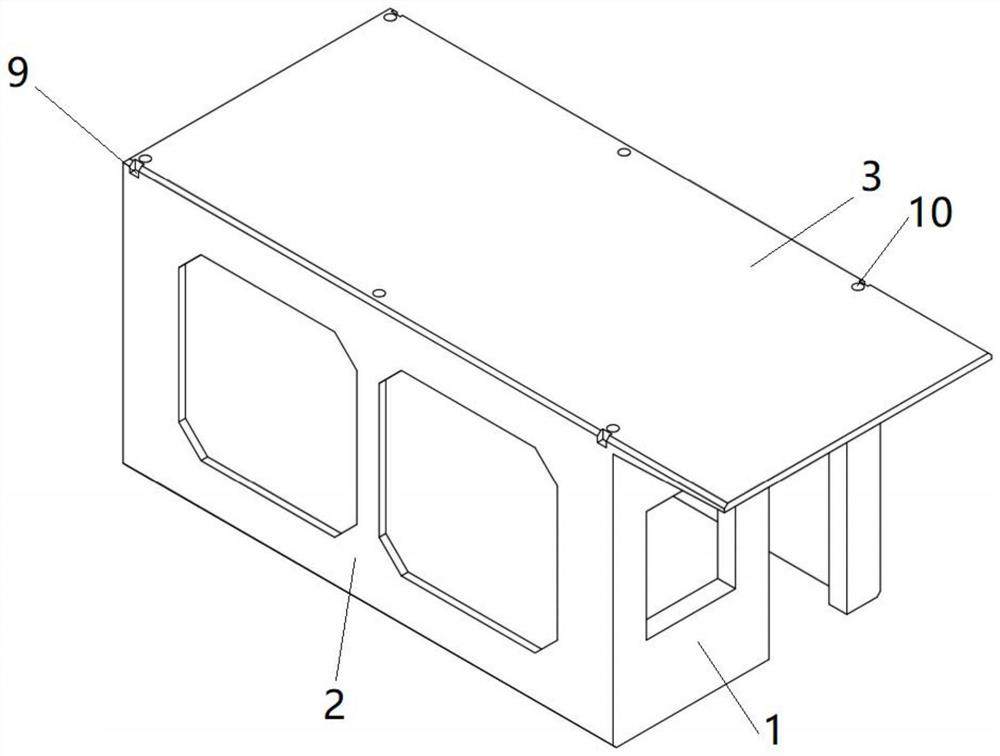

[0043] see Figure 1-3 , the present invention provides a new technical solution: a box-type building, including a wall and an internal structure, the wall is an integrally cast bottomless pentahedron bearing four corners, and the wall includes an outer wall 1, an inner wall 2, and a roof 3 , the outer wall 1 is a composite panel wall surface made of concrete with reserved positions for doors and windows, the inner wall 2 is a reinforced concrete wall surface recessed inward, and the top plate 3 is a box-shaped building. The top is made of well-shaped steel mesh 7 and concrete blocks As for the composite floor slab made, notches 9 are arranged at the four corners of the top plate 3, and the notches 9 are exposed steel bar connection nodes;

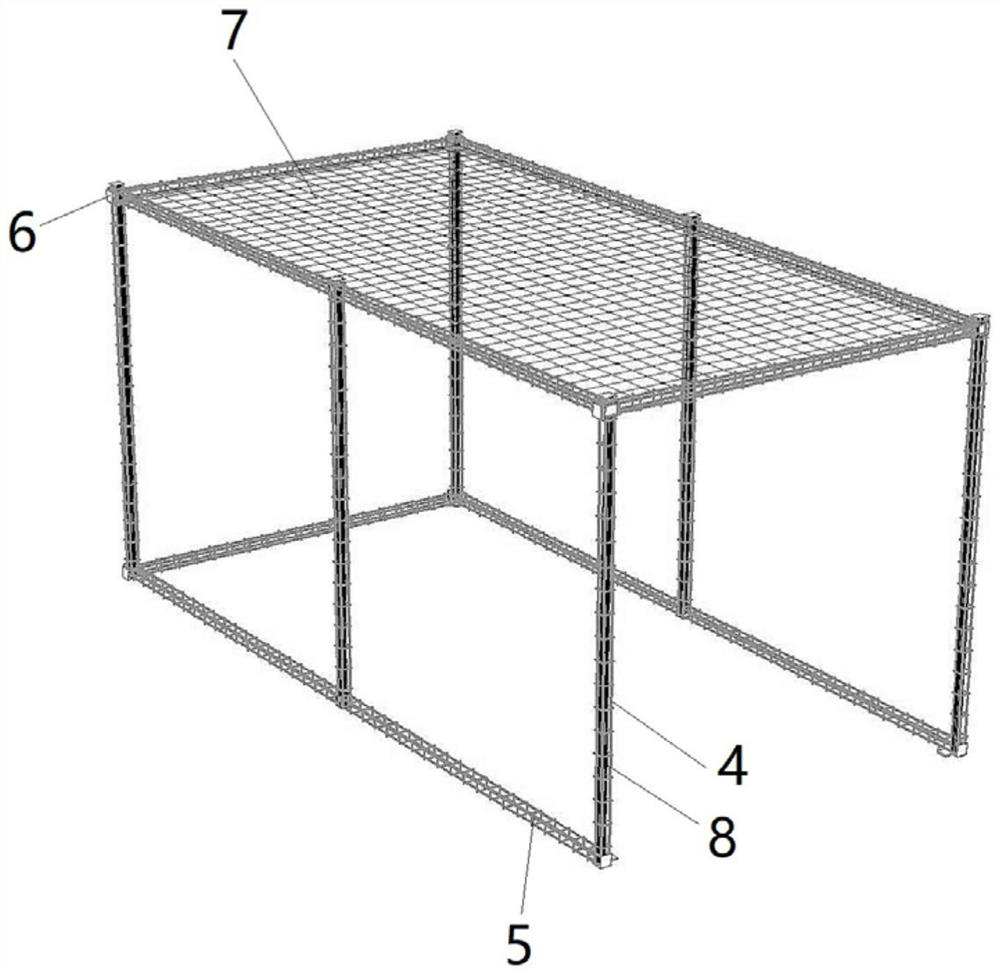

[0044] The internal structure includes column embedded parts 4, beam embedded parts 5, connecting steel plates 6, well-shaped steel mesh 7, and bellows 8. Column embedded parts 4 are six steel columns for longitudinal support, and beam emb...

Embodiment 2

[0047] see Figure 4-11 , the present invention provides a new technical solution: a box-type building that can be stacked side by side into several layers according to needs, and boxes of various structures can be customized according to needs, and different types of combinations can be designed.

[0048] Such as Figure 4 As shown, the box-type building is a combined standard box, which is set as an independent single room, with reserved positions for doors and windows, and it can be composed of several boxes to form multiple layers or rows.

[0049] Such as Figure 5 As shown, the box-type building is a large-door box. The reserved space for doors and windows is removed from the standard box, and the reserved space for the door is made. The internal structure remains unchanged. Two large-style boxes can also be combined according to needs. The corresponding interior walls between the boxes are canceled or cut off during production. For every box on an interior wall that i...

Embodiment 3

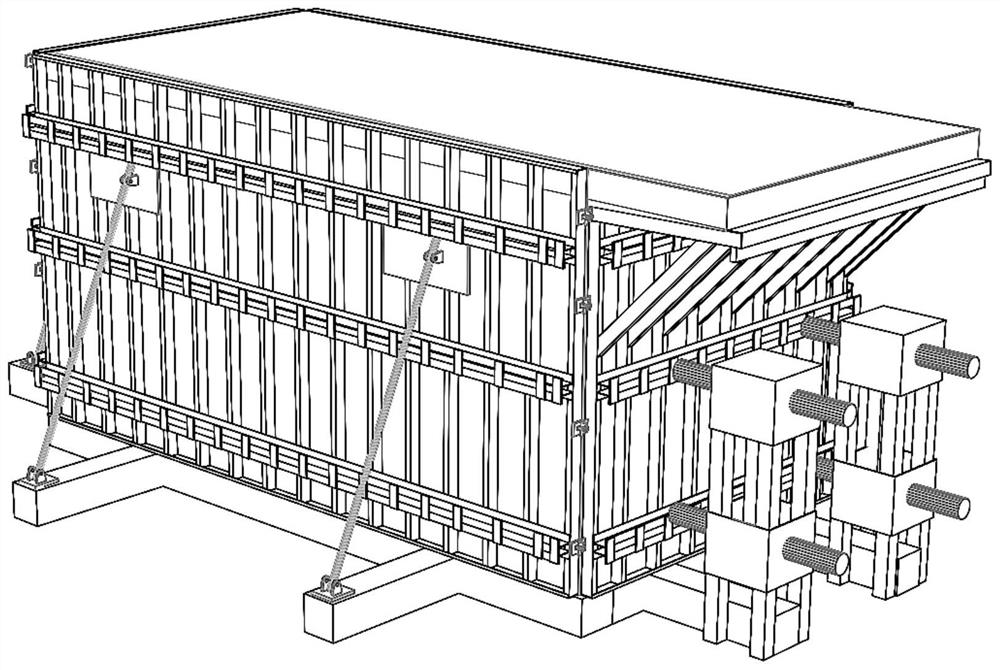

[0054] The production method of box type building, comprises the steps:

[0055] All boxes and other concrete elements are produced by the processing plant. The box casting is produced in the open air using a shaping mold and is integrally formed. All the boxes are bottomless pentahedrons with load-bearing four corners. The outer wall of the box is a composite panel made of concrete and polystyrene board with a thickness of 150mm. The inner wall is reinforced concrete with a thickness of 70mm and recessed inward by 50mm. The inner walls between them are 240mm thick in total, and there is a 100mm air barrier in between, which is good for sound insulation. The top slab of the box is a combined floor slab of well-tac-toe steel mesh and aerated concrete blocks, with a thickness of 150mm. All boxes are C30 concrete and other components are C20 concrete.

[0056] (1) No. 525 early-strength ordinary Portland cement is selected for use in the production of the box, mixed with NC ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com