Wall-broken ganoderma lucidum spore powder soft sweets and preparation method thereof

A technology of broken-wall Ganoderma lucidum spore powder and a production method, which are applied in confectionery, confectionery industry, food science and other directions to achieve the effects of improving edible taste, improving preparation efficiency and dense taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Single factor experiment on the formula of broken wall ganoderma lucidum spore powder soft candy

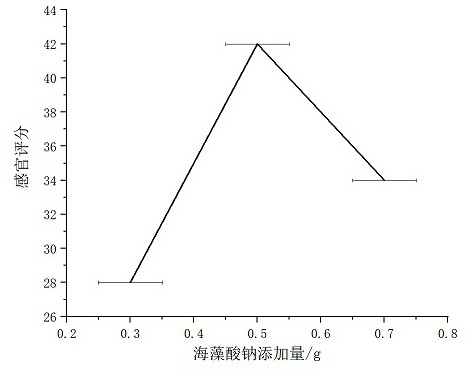

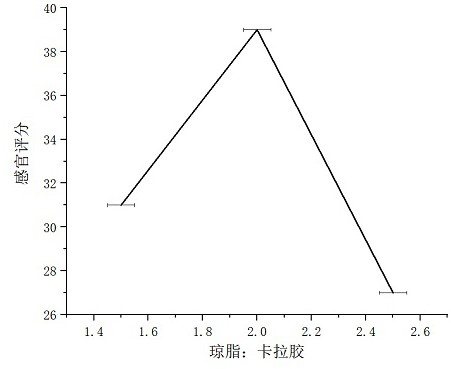

[0029] The dosage of sweetener (xylitol 2.2g, sucralose 0.04g, apple essence 0.4g), acidity regulator (citric acid 1.0g), and preservative (potassium sorbate 0.2g) were set as fixed factors. The amount of gelling agent (agar powder and carrageenan), the ratio of composite gelling agent (agar powder and carrageenan), and the amount of thickening agent (sodium alginate) were carried out in a three-factor and three-level single-factor experiment.

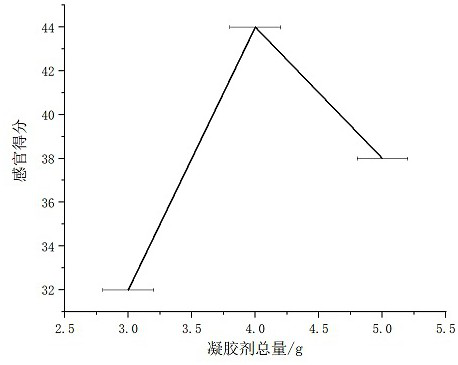

[0030] 1. The amount of compound gelling agent added

[0031] Fix the dosage of other excipients, set the ratio of composite gelling agent (agar powder: carrageenan) to 2:1, thickener (sodium alginate) 0.3g, and explore the effect of the addition amount of composite gelling agent on the quality of soft candy , set the three levels to: 3g, 4g, 5g. Using the method of sensory evaluation, the optimal amount of compound gelling agent...

Embodiment 2

[0041] Response surface experiment on the formulation of broken-wall Ganoderma lucidum spore powder soft candy

[0042] The response surface experiment was carried out with three factors: the amount of compound gelling agent, the compounding ratio of agar and carrageenan, and the amount of sodium alginate, and the response surface analysis data of three factors and three levels were obtained as shown in Table 2. 17 test points The response surface analysis and sensory scoring results are shown in Table 3.

[0043] Level factor -1 0 1 A Amount of gelling agent added / g 3 4 5 B Sodium alginate / g 0.3 0.5 0.7 C Gel ratio 1.5:1 2.0:1 2.5:1

[0044] Test number A / g B C / g Sensory Score 1 3 0.3 2.0:1 32.9 2 5 0.3 2.0:1 29.9 3 3 0.7 2.0:1 32.6 4 5 0.7 2.0:1 32 5 3 0.5 1.5:1 35.7 6 5 0.5 1.5:1 35.5 7 3 0.5 2.5:1 34.8 8 5 0.5 2.5:1 28.7 9 4 0.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com