Method for producing high-purity liquid sulfur trioxide for electronic grade sulfuric acid

A liquid sulfur trioxide, production method technology, applied in the field of electronic chemicals, can solve the problems of raw material purity difference, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

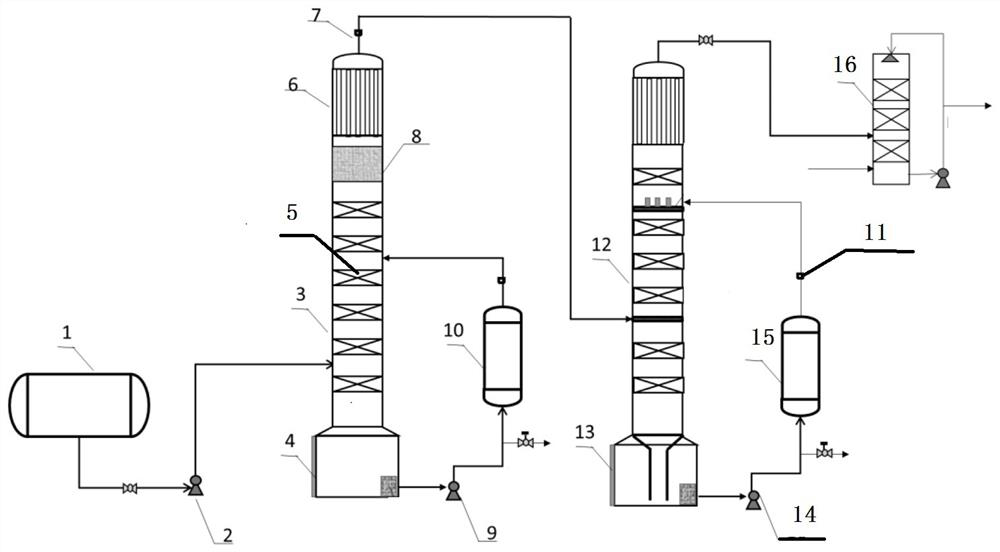

Embodiment 1

[0030] Use 99.5% industrial sulfur trioxide with metal ion content (calculated as Fe)>0.05% and sulfur dioxide content>0.4% as raw material, enter the weight removal tower at 35°C, control the liquid level of the weight removal tower at 53%, and reboil The outlet temperature of the device is controlled at 44°C, the best working feed temperature, and the gas outlet temperature at the top of the weight removal tower is controlled at 44°C. The sulfur trioxide in the weight removal tower is azeotropically evaporated by the heater, and the sulfur trioxide is converted into a gaseous state. The liquid form falls back to the bottom of the tower, and at the same time, the liquid in the heavy component is extracted at a volume fraction of 35%, and the rest is heated by the reboiler again and then enters the weight removal tower. The sulfur trioxide at the top of the weight removal tower enters the light removal tower at the dew point temperature. The liquid level in the tower tank of th...

Embodiment 2

[0032]Use 99.4% industrial sulfur trioxide with metal ion content (calculated as Fe) > 0.06%, and sulfur dioxide content > 0.5% as raw material, enter the weight removal tower at 36°C, control the liquid level of the weight removal tower at 63%, and reboil The outlet temperature of the device is controlled at 46°C, and the gas outlet temperature at the top of the weight removal tower is controlled at 45°C. The sulfur trioxide in the weight removal tower is azeotropically evaporated by the heater, and the sulfur trioxide is converted into a gaseous state, and the heavy components fall back to the bottom of the tower in liquid form. At the same time, the liquid in the heavy component is produced with a volume fraction of 36%, and the rest is heated by the reboiler again and then enters the de-weighting tower. The liquid level in the tower tank of the light removal tower is controlled at 65%, the outlet temperature of the heater is controlled at 38°C, and the gas outlet temperatur...

Embodiment 3

[0034] Use industrial sulfur trioxide with 99.3%, metal ion content (calculated as Fe)>0.07%, and sulfur dioxide content>0.5% as raw material, enter the weight removal tower at 36°C, control the liquid level of the weight removal tower at 75%, and reboil The outlet temperature of the device is controlled at 48°C, and the gas outlet temperature at the top of the weight removal tower is controlled at 46°C. The sulfur trioxide in the weight removal tower is azeotropically evaporated by the heater, and the sulfur trioxide is converted into a gaseous state, and the heavy components fall back to the bottom of the tower in liquid form. At the same time, the liquid in the heavy component is extracted at a volume fraction of 45%, and the rest is heated by the reboiler again and then enters the de-weighting tower. The liquid level in the tower tank of the light removal tower is controlled at 76%, the outlet temperature of the heater is controlled at 41°C, and the gas outlet temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com