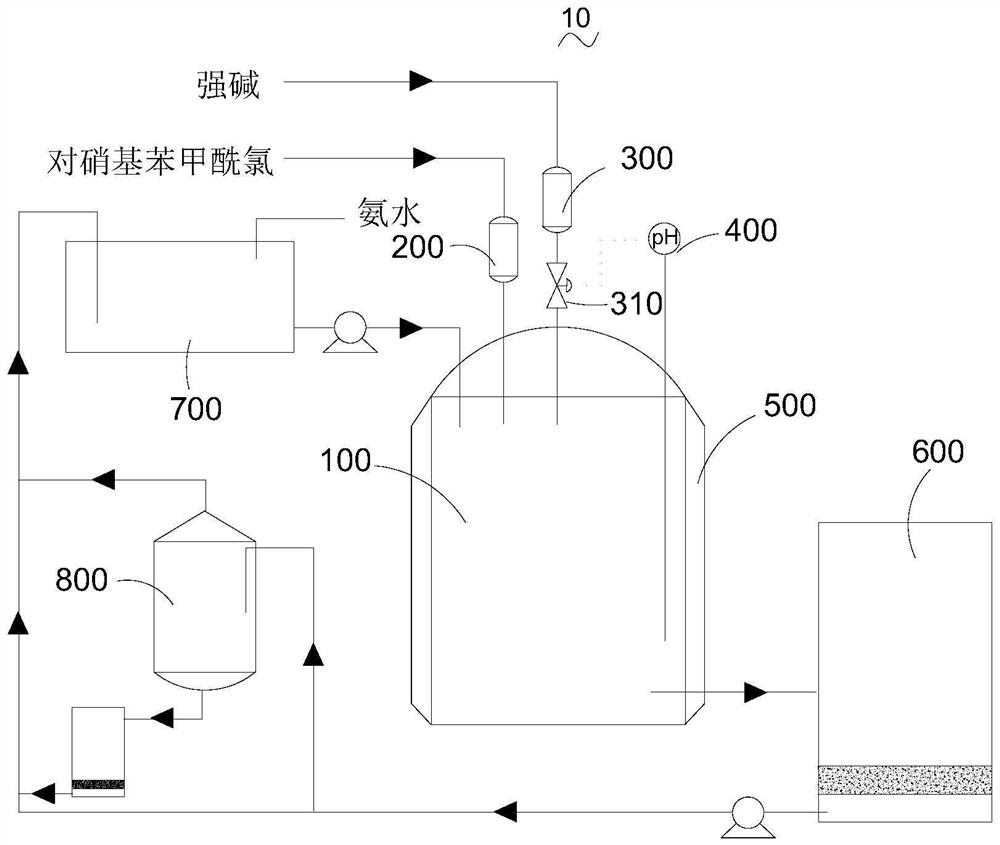

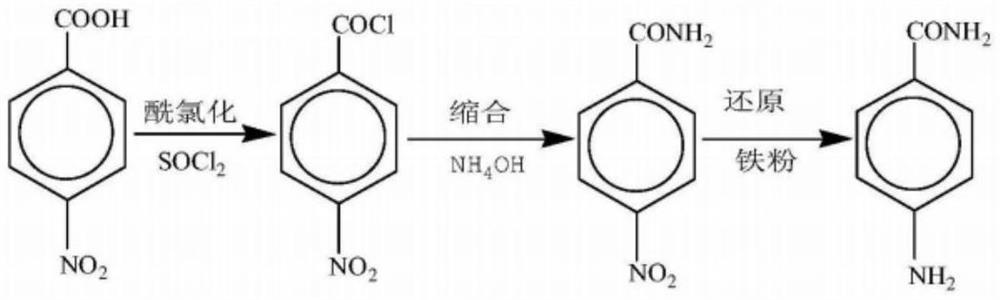

Production method and production system of p-nitrobenzamide

A technology of nitrobenzamide and nitrobenzoyl chloride is applied in the field of production methods and production systems of p-nitrobenzamide, and can solve the problems of waste of resources, difficulty in wastewater treatment, high ammonia nitrogen content in wastewater, and high cost, and achieves the Achieve cleaner production, reduce ammonia nitrogen content, and reduce the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

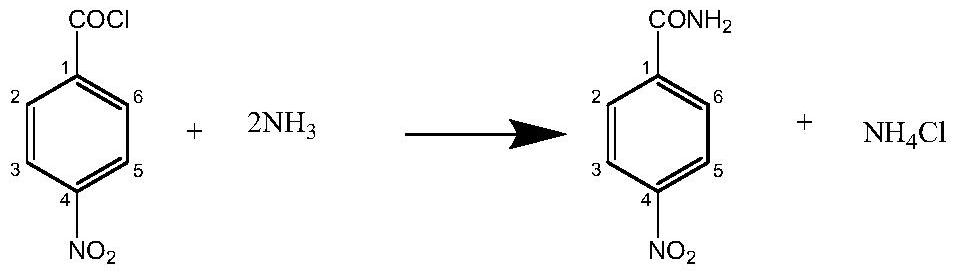

Method used

Image

Examples

experiment example 1

[0063] Configuration mass concentration is 10% ammonia solution, get 95g of this ammonia solution, add in the four-necked flask, be warmed up to 75 ℃, in the four-necked flask, drip the p-nitrobenzoyl chloride of melting, reduce to the pH value of reaction solution to below 10. In the four-necked flask, dropwise add 10% NaOH solution simultaneously, adjust the pH value of reaction solution respectively to be 8~9,9~10,10~11,11~12, drop 92.8g ( 0.5mol) of molten p-nitrobenzoyl chloride. The temperature of the reaction solution was raised to 85° C. and kept for 1 h. Cool down to room temperature, filter the feed liquid to obtain a mixture of solid p-nitrobenzamide and p-nitrobenzoyl chloride, the liquid is NaCl solution, and test the content of solid p-nitrobenzamide and p-nitrobenzoyl chloride , to test the ammonia nitrogen content of the NaCl solution, and the test results are shown in Table 1.

[0064] Table 1 Experimental Example 1 Test Results

[0065]

experiment example 2

[0067] Configure ammonia water mixed solution A. In ammonia water mixed solution A, the mass concentration of ammonia water is 10%, and the mass concentration of NaCl is 10%. Molten p-nitrobenzoyl chloride was added dropwise until the pH value of the reaction solution was lowered to below 10. In the four-necked flask, dropwise add 10% NaOH solution simultaneously, adjust the pH value of reaction solution respectively to be 8~9,9~10,10~11,11~12, drop 92.8g ( 0.5mol) of molten p-nitrobenzoyl chloride. The temperature of the reaction solution was raised to 85°C and kept for 2h. Cool down to room temperature, filter the feed liquid to obtain a mixture of solid p-nitrobenzamide and p-nitrobenzoyl chloride, the liquid is NaCl solution, and test the content of solid p-nitrobenzamide and p-nitrobenzoyl chloride , to test the ammonia nitrogen content of the NaCl solution, and the test results are shown in Table 2.

[0068] Table 2 Experimental Example 2 Test Results

[0069]

experiment example 3

[0071] Using the waste water generated in Experimental Example 2, a mixed solution of ammonia and water was prepared. In the mixed solution of ammonia and water, the mass concentration of ammonia was 10%. Take 95g of the aqueous ammonia solution, put it into a four-necked flask, raise the temperature to 80°C, and drop molten p-nitrobenzoyl chloride into the four-necked flask until the pH value of the reaction solution drops below 10. In the four-necked flask, dropwise add 10% NaOH solution simultaneously, adjust the pH value of reaction solution respectively to be 8~9,9~10,10~11,11~12, drop 92.8g ( 0.5mol) of molten p-nitrobenzoyl chloride. The temperature of the reaction solution was raised to 85°C and kept for 2h. Cool down to room temperature, filter the feed liquid to obtain a mixture of solid p-nitrobenzamide and p-nitrobenzoyl chloride, the liquid is NaCl solution, and test the content of solid p-nitrobenzamide and p-nitrobenzoyl chloride , to test the ammonia nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com