Preparation process and structure of MTM type anti-fuse unit based on ONO medium

A preparation process and anti-fuse technology, applied in electrical components, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc., can solve the problems of high programming power consumption, small memory capacity, large chip area, etc., to reduce programming current, Strong operability, the effect of reducing static power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preparation process and structure of an ONO medium-based MTM antifuse unit proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

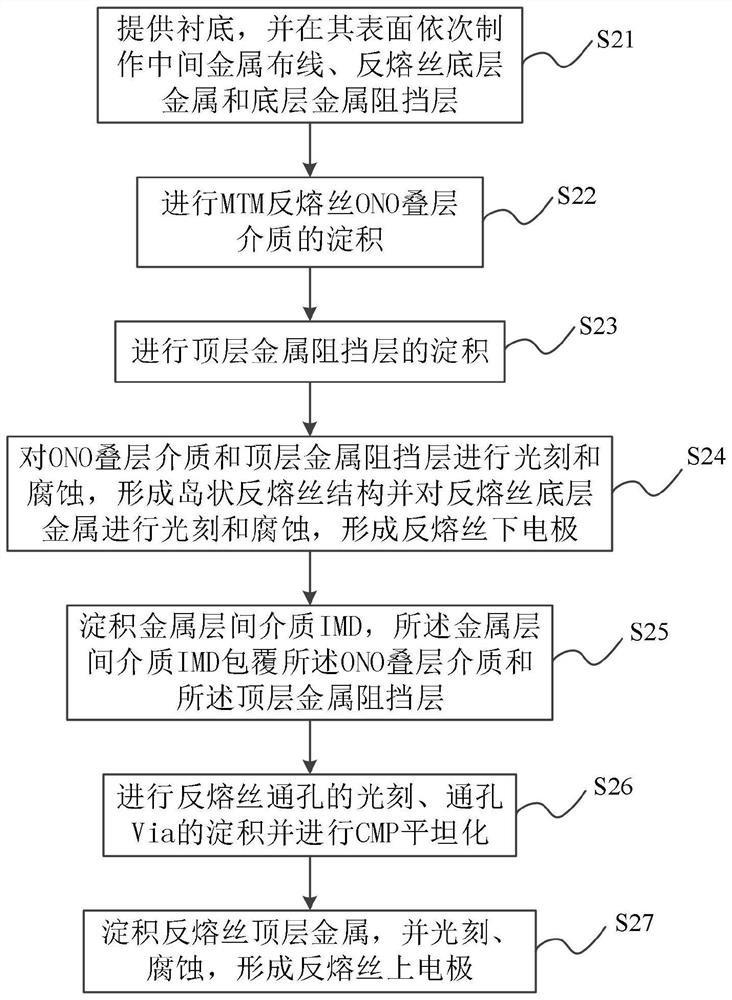

[0042] The invention provides a preparation process of an MTM type antifuse unit based on an ONO medium, the process of which is as follows figure 2 shown, including the following steps:

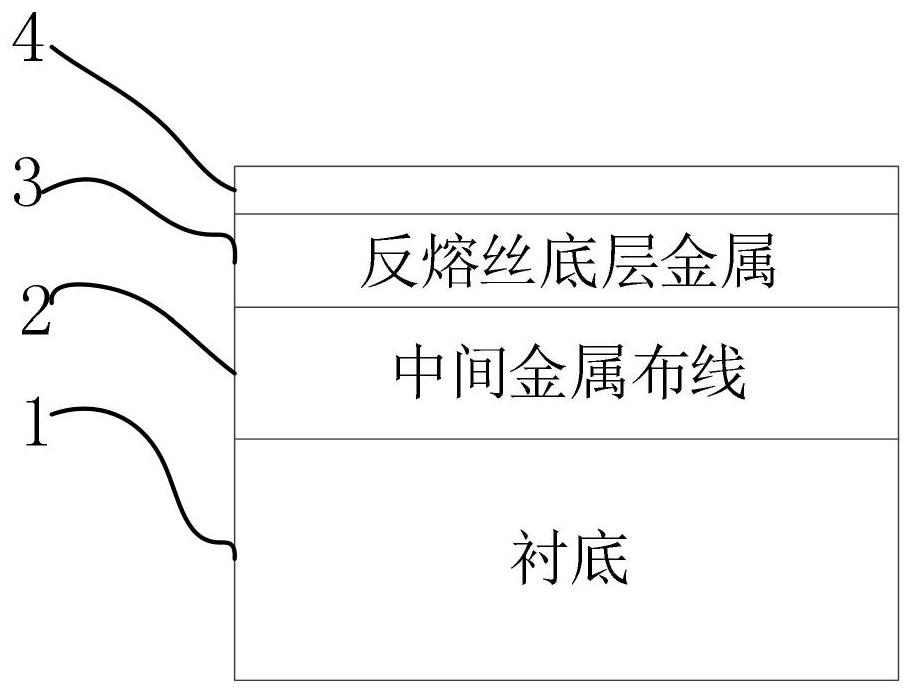

[0043] Step S21, providing a substrate, and sequentially fabricating MOS device levels and intermediate metal wiring, antifuse bottom metal and bottom metal barrier layer on its surface;

[0044] Step S22, depositing the MTM antifuse ON...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com