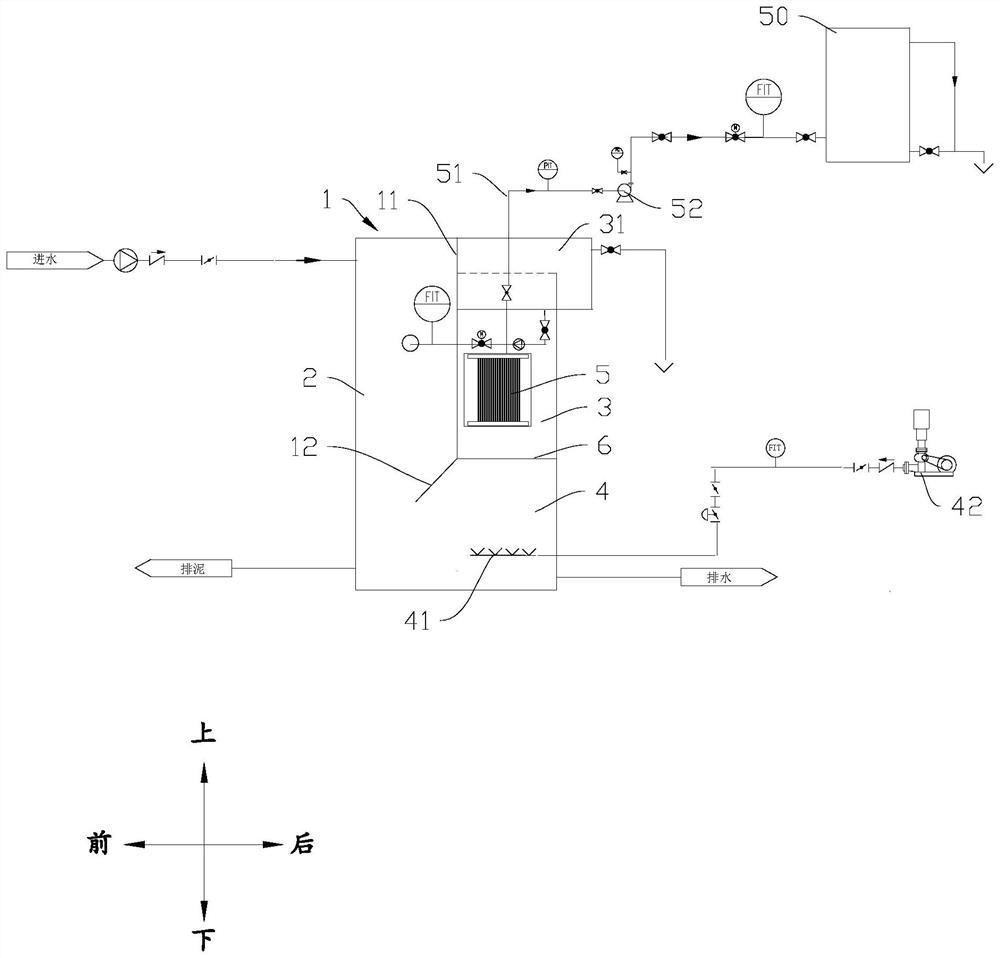

Wastewater treatment system

A wastewater treatment system and water seal technology, applied in the field of wastewater treatment, can solve the problems of low space utilization, difficult installation, waste of exhaust gas, etc., and achieve the effects of reduced operating costs, high space utilization, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: see Figure 13 , when the membrane flux is 18LMH, the air volume fluctuates from 5 to 12Nm3 / h, and the sludge concentration is maintained between 11000 and 12000mg / L. The change of water permeability is shown in the figure below. 0.18LMH / bar.h.

Embodiment 2

[0077] Example 2: see Figure 14 In this example, when the membrane operating flux is 30LMH, the sludge concentration is 4000-14000mg / L, and the air volume is 4-8Nm3 / h, the membrane system operates stably, and the decay rate of water permeability is about 0.16LMH / bar.h.

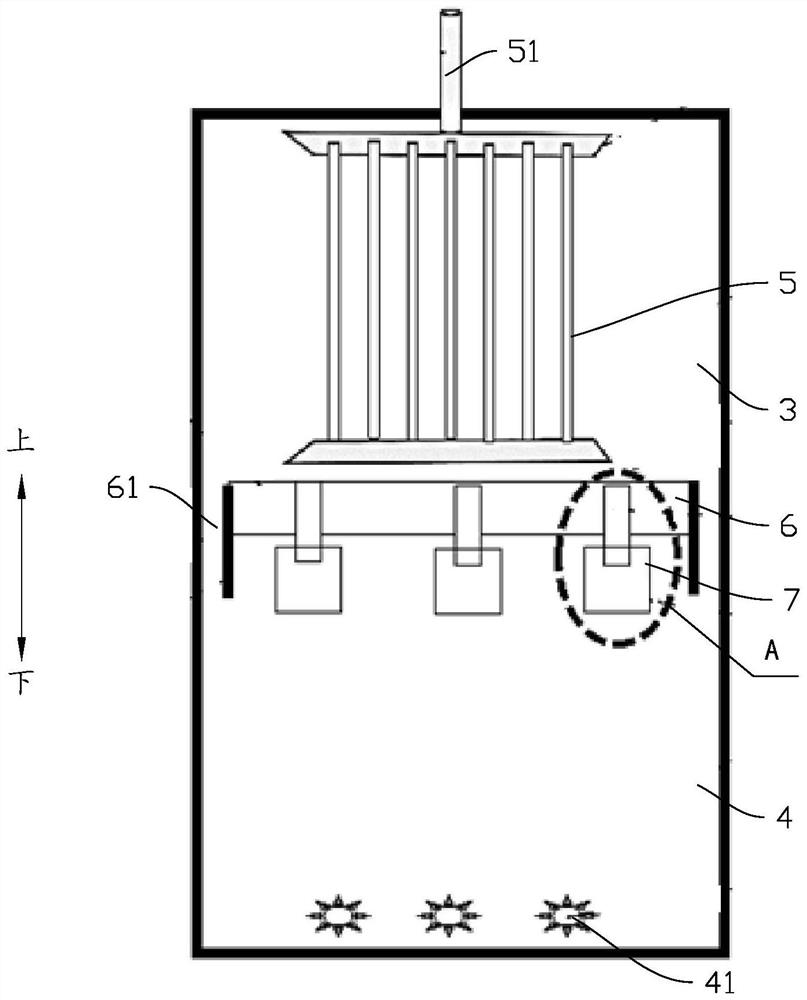

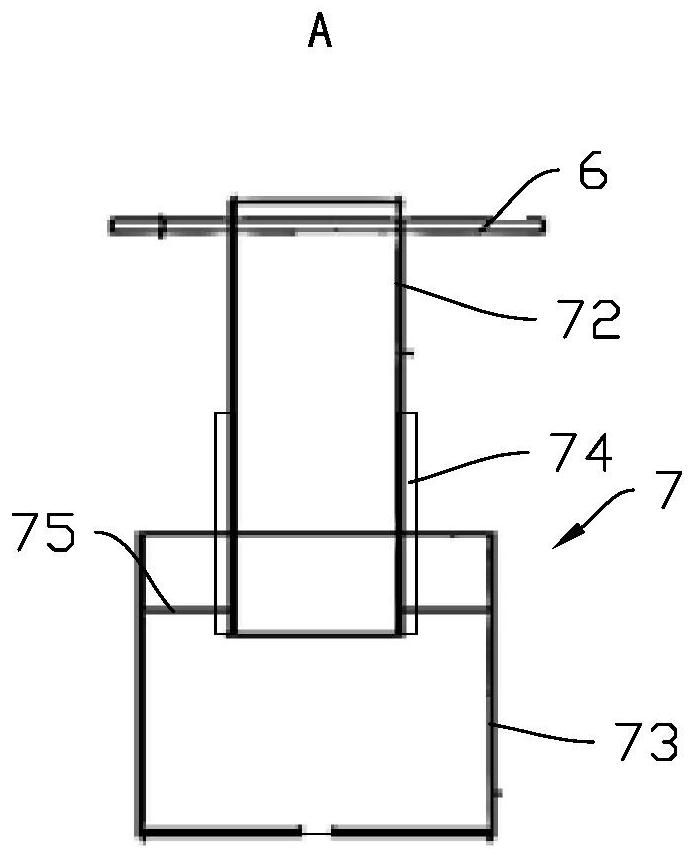

[0078] During the operation of Examples 1 and 2, the floating and mud collection conditions of the floating membrane frame 50 are always good, and the water permeability of the membrane operation is always stable, which proves that the floating membrane frame 50 and the combined aeration system are technically feasible.

[0079] The comparison between the embodiment of the present invention and traditional A / O MBR:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com