Glazed tile with bright star effect on surface and preparation method of glazed tile

A glazed tile and surface glaze technology, applied in the field of glazed tile and its preparation, can solve problems such as affecting the flatness of the glazed tile, and achieve the effects of high flatness of the glazed surface, improved antifouling performance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

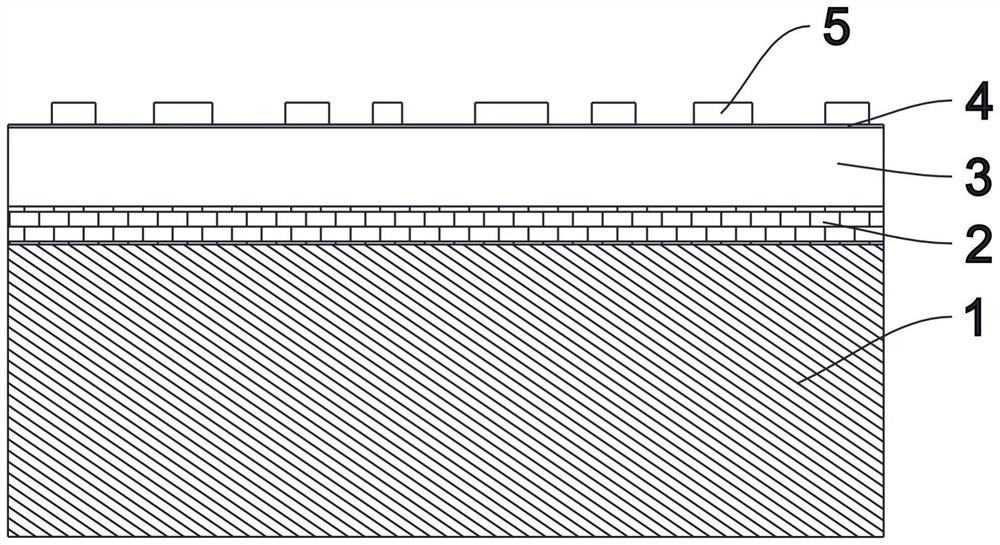

[0047] A method for preparing glazed tiles with a bright star effect on the surface, comprising the steps of:

[0048] a. Calculated in parts by weight, the raw materials in the frit include the following components: 12 parts of calcite, 15 parts of barium carbonate, 36 parts of potassium feldspar, 6 parts of zinc oxide, 15 parts of kaolin, 4 parts of calcium borate, 2 parts of soda ash, 10 parts of quartz sand, weighing raw materials. After the raw materials are mixed, they are put into the frit furnace to be calcined and melted at 1450°C, and then flow out of the frit furnace and quenched into frit particles for later use.

[0049] Calculated by mass percentage, the chemical composition of the frit is: SiO 2 50.6%, Al 2 o 3 11.4%, MgO 0.35%, CaO 8.9%, Na 2 O is 1.5%, K 2 O is 4.5%, BaO is 13.3%, ZnO is 6.5%, B 2 o 3 2.2%, TiO 2 0.1%, Fe 2 o 3 It is 0.2%, and the balance is loss on ignition.

[0050]b. Weigh 71 parts of frit, 15 parts of zirconium silicate, 5 parts...

Embodiment 2

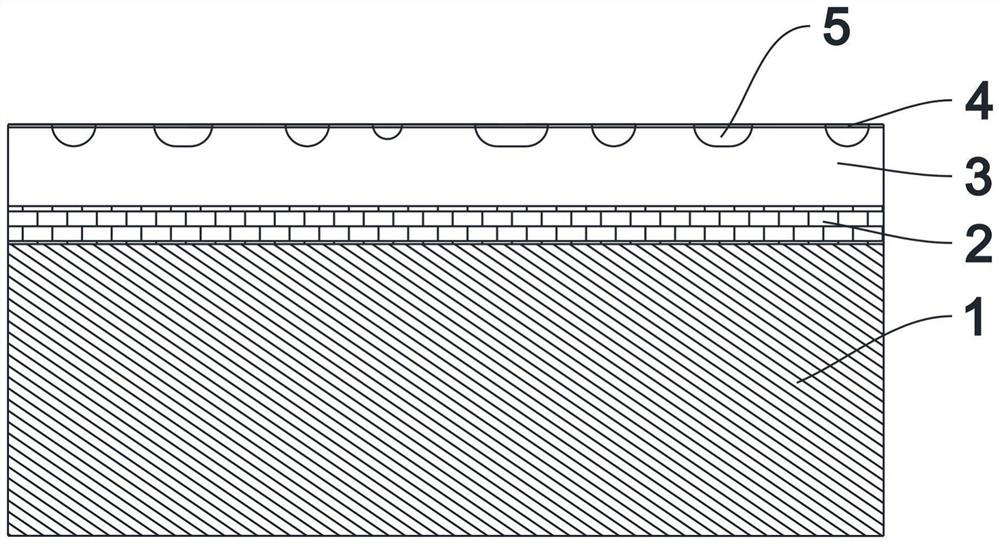

[0059] A method for preparing glazed tiles with a bright star effect on the surface, comprising the following steps:

[0060] a. Calculated in parts by weight, the raw materials in the frit include the following components: 10 parts of calcite, 18 parts of barium carbonate, 36 parts of potassium feldspar, 5 parts of zinc oxide, 15 parts of kaolin, 4 parts of calcium borate, 2 parts of soda ash, 10 parts of quartz sand, weighing raw materials. After the raw materials are mixed, they are put into the frit furnace to be calcined and melted at 1600°C, and then flow out of the frit furnace and quenched into frit particles for later use.

[0061] Calculated by mass percentage, the chemical composition of the frit is: SiO 2 50.6%, Al 2 o 3 11.5%, MgO 0.35%, CaO 7.0%, Na 2 O is 1.5%, K 2 O is 4.5%, BaO is 16%, ZnO is 6.0%, B 2 o 3 2.3%, TiO 2 0.1%, Fe 2 o 3 0.2%.

[0062] b. Weigh 90 parts of frit, 2 parts of zirconium silicate, 4 parts of calcined kaolin, 4 parts of air-kn...

Embodiment 3

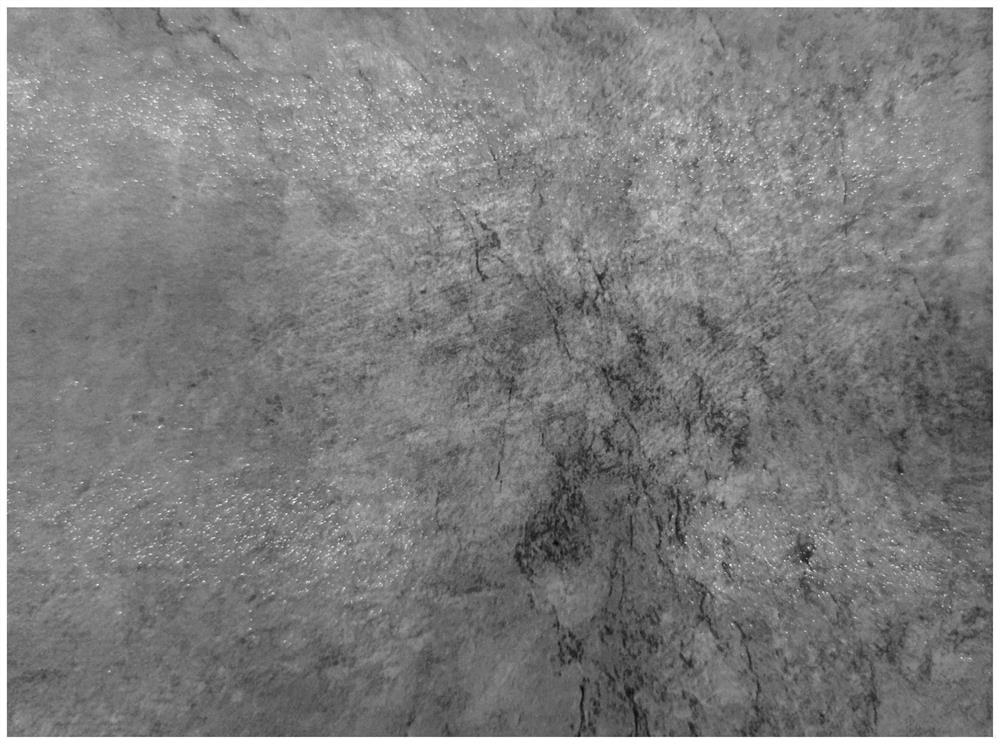

[0071] A method for preparing glazed tiles with a bright star effect on the surface, comprising the following steps:

[0072] a. Calculated in parts by weight, the raw materials in the frit include the following components: 14 parts of calcite, 12 parts of barium carbonate, 40 parts of potassium feldspar, 7 parts of zinc oxide, 12 parts of kaolin, 4 parts of calcium borate, 1 part of soda ash, 10 parts of quartz sand, weighing raw materials. After the raw materials are mixed, they are put into the frit furnace to be calcined and melted at 1500°C, and then flow out of the frit furnace and quenched into frit particles for later use.

[0073] Calculated by mass percentage, the chemical composition of the frit is: SiO 2 52%, Al 2 o 3 10%, MgO 0.35%, CaO 10.5%, Na 2 O is 1.0%, K 2 O is 5.0%, BaO is 10.5%, ZnO is 7.7%, B 2 o 3 2.3%, TiO 2 0.1%, Fe 2 o 3 It is 0.3%, and the balance is loss on ignition.

[0074] b. Weigh 80 parts of frit, 12 parts of zirconium silicate, 8 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com