Preparation method of artificial humic acid urea slow-release fertilizer

A humic acid urea, slow-release fertilizer technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of nitrogen fertilizer loss of soil and environment, unstable product quality, excessive heavy metals, etc. Slow release effect, effect of high nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

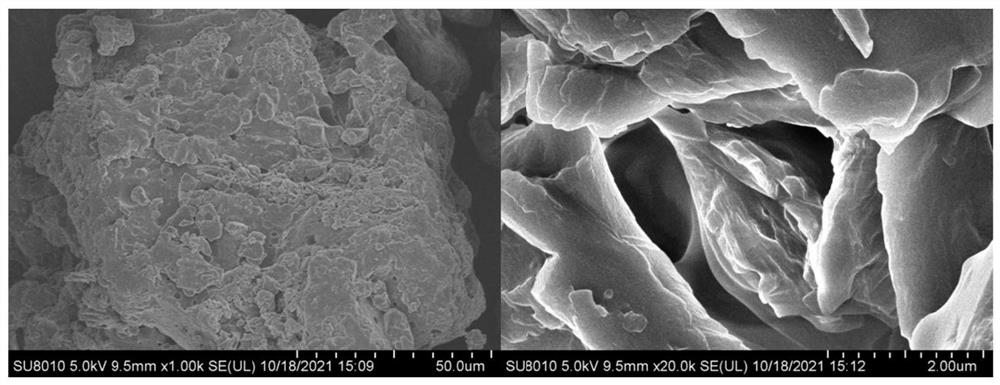

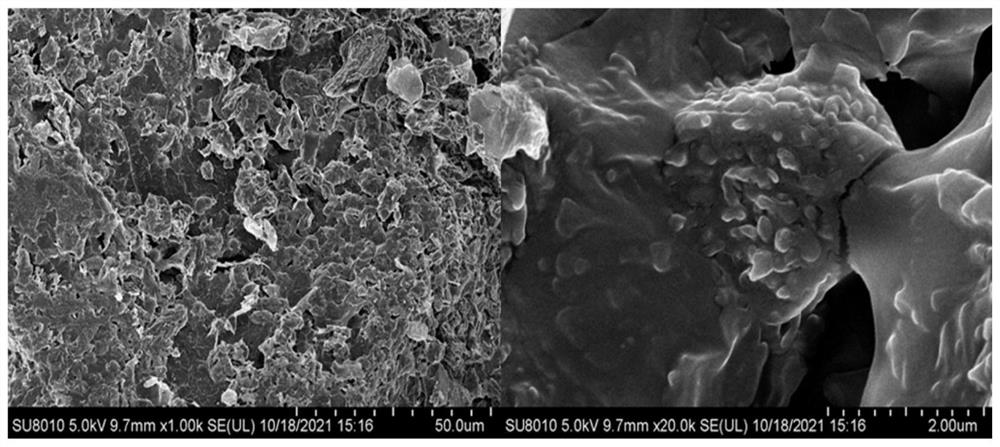

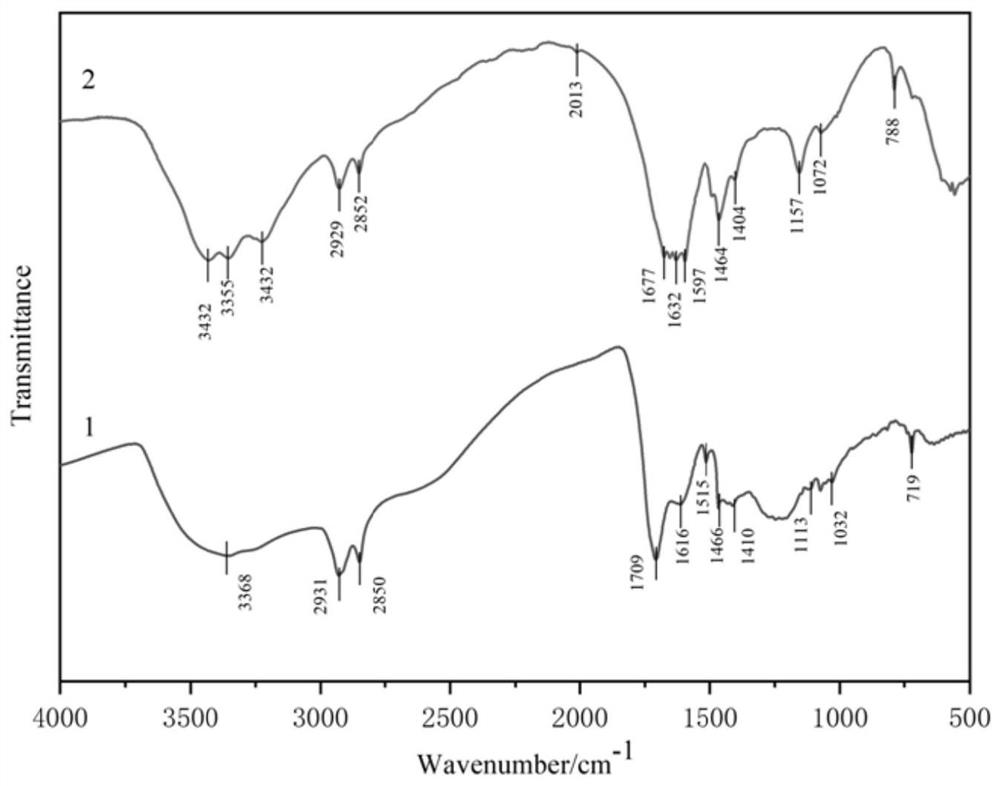

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the preparation method of a kind of artificial humic acid urea slow-release fertilizer of present embodiment is finished according to the following steps:

[0025] 1. Mix the biomass powder, active additives and water into the reactor, control the temperature rise program of the reactor, conduct the hydrothermal humification reaction of the biomass powder under high temperature and high pressure conditions, and then cool to room temperature to obtain the artificial Solid-liquid mixed products of humic substances;

[0026] 2. Suction filter the solid-liquid mixed product containing artificial humus, remove the solid, and obtain the artificial humus liquid; adjust the pH value of the artificial humus liquid to 1, and then leave it to stand to obtain a solid substance; use deionized water as a cleaning agent, The solid matter is subjected to several times of centrifugal cleaning to neutrality, and then vacuum-dried to obtain artificial humic acid s...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the biomass powder described in step 1 is one or a mixture of rice straw, corn stalk, soybean straw, leaves and sawdust, The particle size of the biomass powder is 50 mesh to 100 mesh. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the active auxiliary agent described in step one is NaOH, KOH, industrial soda ash and Ca(OH) 2 , Ca(OH) 2 with Na 2 CO 3 One or a mixture of several of them. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com