Feather cleaning agent and preparation method thereof

A cleaning agent and feather technology, applied in the field of feather cleaning agent and its preparation, can solve the problems of water pollution, feather damage, unscientific composition ratio, etc., and achieve the requirements of low production equipment, reduce production cost, and improve product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

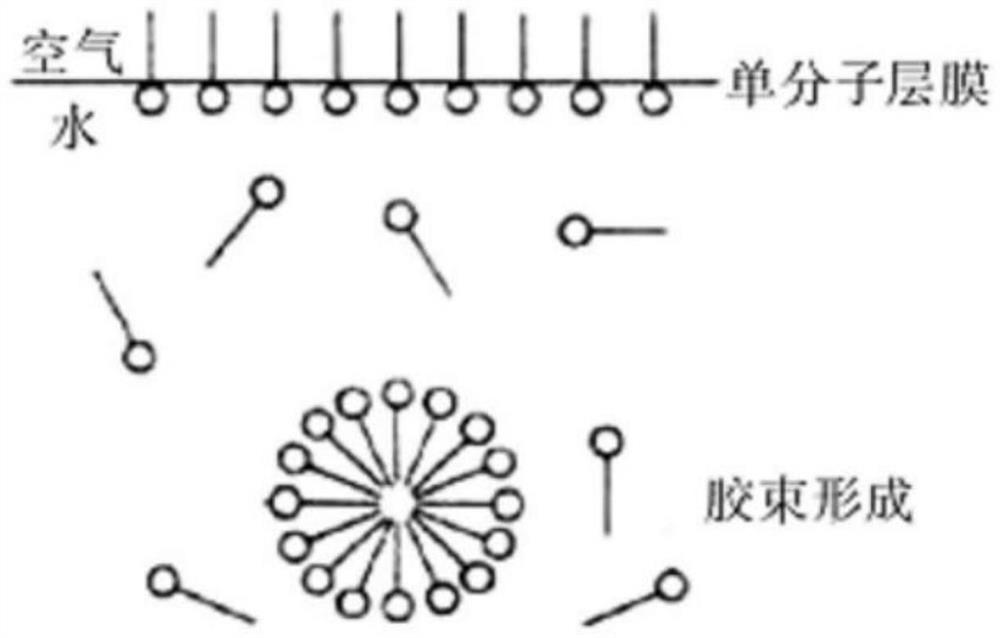

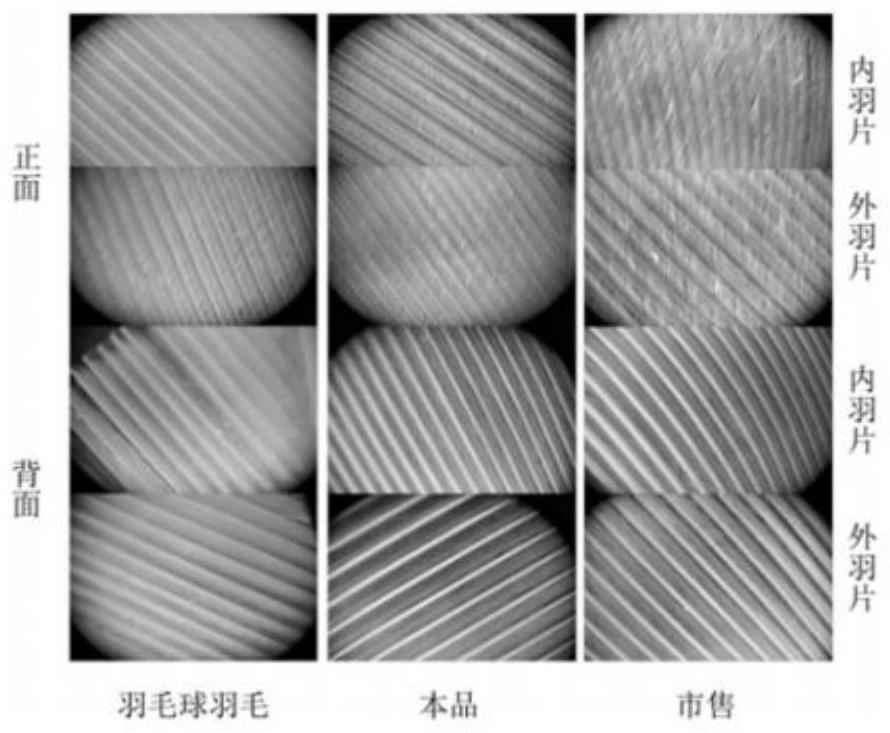

Method used

Image

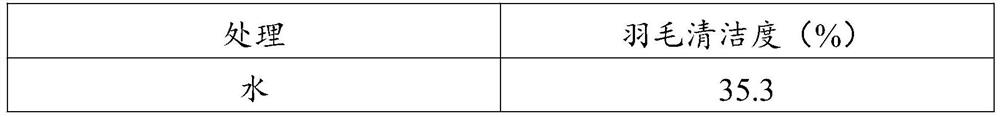

Examples

Embodiment 1

[0039] The present embodiment provides a kind of preparation method of fulvic acid feather cleaning agent, specifically comprises the following steps:

[0040] 1) In terms of parts by mass, take the following components: 5 parts of mineral source fulvic acid, 1 part of sodium edetate, 5 parts of sodium dodecylbenzenesulfonate, 1 part of AEO-9, octylphenol 5 parts of oxyethylene ether, 1 part of tea saponin, 1 part of sodium hydroxide, 1 part of sodium carboxymethyl cellulose, 2 parts of sodium xylene sulfonate, 100 parts of water;

[0041] 2) the mineral source fulvic acid is prepared as a 3wt% mineral source fulvic acid aqueous solution;

[0042] 3) sodium carboxymethyl cellulose is prepared as a 1wt% sodium carboxymethyl cellulose aqueous solution;

[0043] 4) mixing the ore source fulvic acid aqueous solution with sodium edetate to obtain the first mixed solution;

[0044] 5) mixing sodium carboxymethyl cellulose with the first mixed solution to obtain the second mixed so...

Embodiment 2

[0047]The present embodiment provides a kind of preparation method of fulvic acid feather cleaning agent, specifically comprises the following steps:

[0048] 1) In terms of parts by mass, take the following components: 10 parts of biochemical fulvic acid, 5 parts of sodium edetate, 10 parts of sodium dodecylbenzenesulfonate, 2 parts of AEO-9, octylphenol 8 parts of oxyethylene ether, 3 parts of tea saponin, 2 parts of sodium silicate, 1.5 parts of sodium carboxymethyl cellulose, 3 parts of sodium xylene sulfonate, 120 parts of water;

[0049] 2) preparing biochemical fulvic acid into an 8wt% biochemical fulvic acid aqueous solution;

[0050] 3) Sodium carboxymethyl cellulose is prepared as a 1.5wt% sodium carboxymethyl cellulose aqueous solution;

[0051] 4) mixing the biochemical fulvic acid aqueous solution with sodium edetate to obtain the first mixed solution;

[0052] 5) mixing the sodium carboxymethylcellulose aqueous solution with the first mixed solution to obtain t...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of fulvic acid feather cleaning agent, specifically comprises the following steps:

[0056] 1) In parts by mass, take the following components: 20 parts of biochemical fulvic acid, 5 parts of sodium edetate, 15 parts of sodium dodecylbenzenesulfonate, 3 parts of AEO-9, octylphenol 10 parts of polyoxyethylene ether, 3 parts of tea saponin, 4 parts of sodium sulfate, 1.5 parts of sodium carboxymethyl cellulose, 4 parts of sodium xylene sulfonate, 120 parts of water;

[0057] 2) preparing biochemical fulvic acid into a 5wt% biochemical fulvic acid aqueous solution;

[0058] 3) sodium carboxymethyl cellulose is prepared as a 1wt% sodium carboxymethyl cellulose aqueous solution;

[0059] 4) mixing the biochemical fulvic acid aqueous solution with sodium edetate to obtain the first mixed solution;

[0060] 5) mixing the sodium carboxymethylcellulose aqueous solution with the first mixed solution to obtain the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com