Hydrogel material for promoting cartilage repair as well as preparation method and application of hydrogel material

A cartilage repair and hydrogel technology, applied in medical science, prosthesis, etc., can solve the problems of limited promotion and application potential, cumbersome experimental operation, and technical difficulty, so as to achieve in vivo repair, improve quality, and avoid ethical problems. Effects of related questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In a first aspect, the present invention provides a method for preparing a cartilage-promoting hydrogel material, comprising the following steps:

[0034] (1) BMSCs are pretreated and cultured with transforming growth factor TGF-β, and the BMSCs are stimulated to secrete TGF-β-miRNA-extracellular vesicles after ingesting transforming growth factor TGF-β, and the TGF-β- miRNA-extracellular vesicles were filtered, centrifuged and concentrated, and the TGF-β-miRNA-extracellular vesicle suspension was collected;

[0035] (2) Co-cultivate TGF-β-miRNA-extracellular vesicle suspension and BMSCs to promote BMSCs to absorb TGF-β-containing miRNA-extracellular vesicles to obtain TGF-β-miRNA-extracellular vesicles soaked BMSC;

[0036] (3) Stir and mix the BMSCs containing TGF-β-miRNA-extracellular vesicles with the biocompatible hydrogel to obtain the cartilage-promoting hydrogel material.

[0037] In the present invention, the cartilage refers to a type of connective tissue, w...

Embodiment 1

[0055] Example 1 Preparation of Hydrogel Materials for Promoting Cartilage Repair

[0056] Step 1: Collect TGF-β3-miRNA-EV suspension

[0057] BMSCs were extracted from the femoral bone marrow cavity of healthy adult rats and placed in a medium containing 10% fetal bovine serum (FBS), 1% antibiotics (100U -1 mL Penicillin, 100mg -1 mL streptomycin and 0.25mg -1 mL amphotericin B) solution and 1×10 -3 mol sodium pyruvate (sodium pyruvate) in DMEM (Dulbecco's modified Eagle medium) medium; wherein, the environmental conditions of the cell incubator were set at a temperature of 37 ° C, CO 2 Concentration of 5% and humidity of 95%;

[0058] The DMEM medium was replaced every three days, and the cells were subcultured when the density of BMSC reached 80%;

[0059] When the BMSC proliferates to the third generation, in the above DMEM medium, an additional concentration of 50ng -1 mL of TGF-β3 solution, continue to culture for seven days to obtain TGF-β3-miRNA-extracellular ves...

Embodiment 2

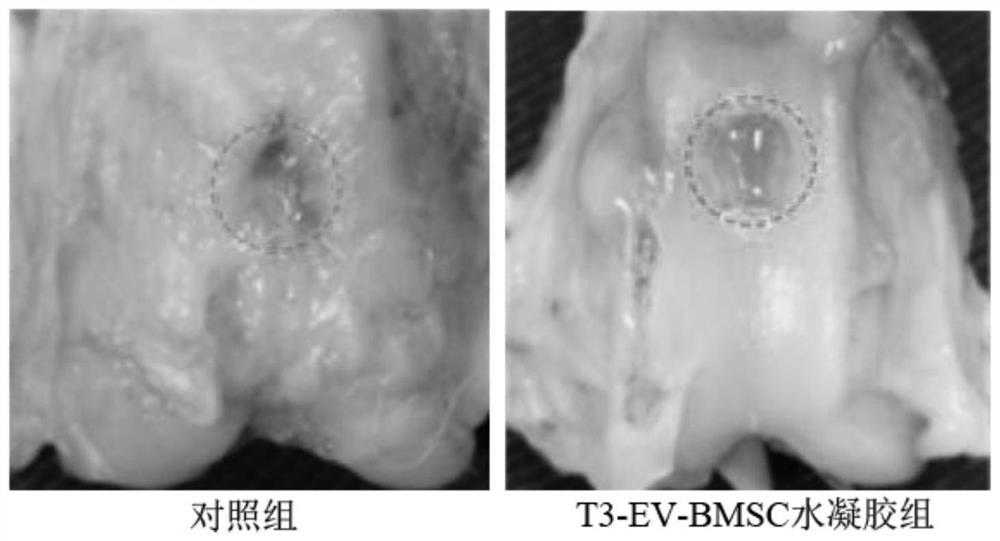

[0073] Example 2 Application of Hydrogel Materials for Promoting Cartilage Repair in Rat Knee Articular Cartilage

[0074] Take 2mL of the cartilage-repairing hydrogel material prepared in Example 1 (the cell number of T3-EV-BMSC is 5×10 8 ), injected with a syringe to the injured part of the articular cartilage in the rat knee joint cavity, once a week, and injected continuously for eight weeks. The repair of articular cartilage in the rat knee joint cavity after eight weeks after operation is shown in figure 1 . from figure 1 The results can be seen that the surface of the damaged cartilage in the control group was filled with a large amount of granulation tissue, while the damaged cartilage in the knee joints of rats injected with the hydrogel material for promoting cartilage repair (T3-EV-BMSC hydrogel group) The surface of the site is filled with new tissue, the surface is smooth and flat, and there is no obvious boundary with the surrounding tissue. Therefore, the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com