Process for separating sugar and acid by using quasi-two-dimensional chromatography

A two-dimensional chromatography and process technology, which is applied in the technological field of separating sugar and acid by quasi-two-dimensional chromatography, can solve the problems of sugar recovery rate and purity cannot be guaranteed at the same time, recovery rate and purity restriction, membrane easily polluted, etc. Achieve the effect of low cost, low equipment requirements and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

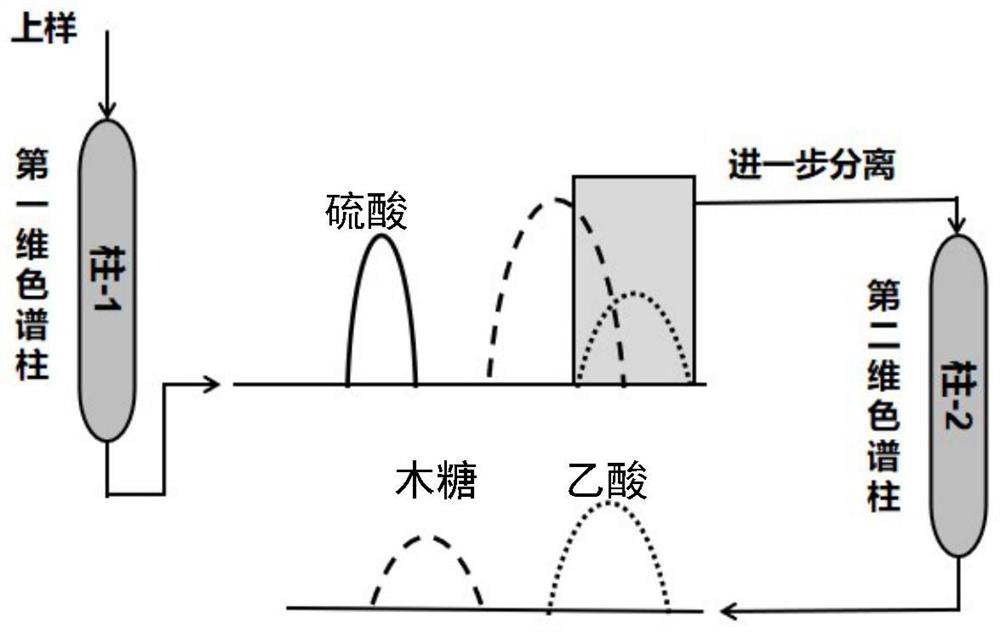

Method used

Image

Examples

Embodiment 1

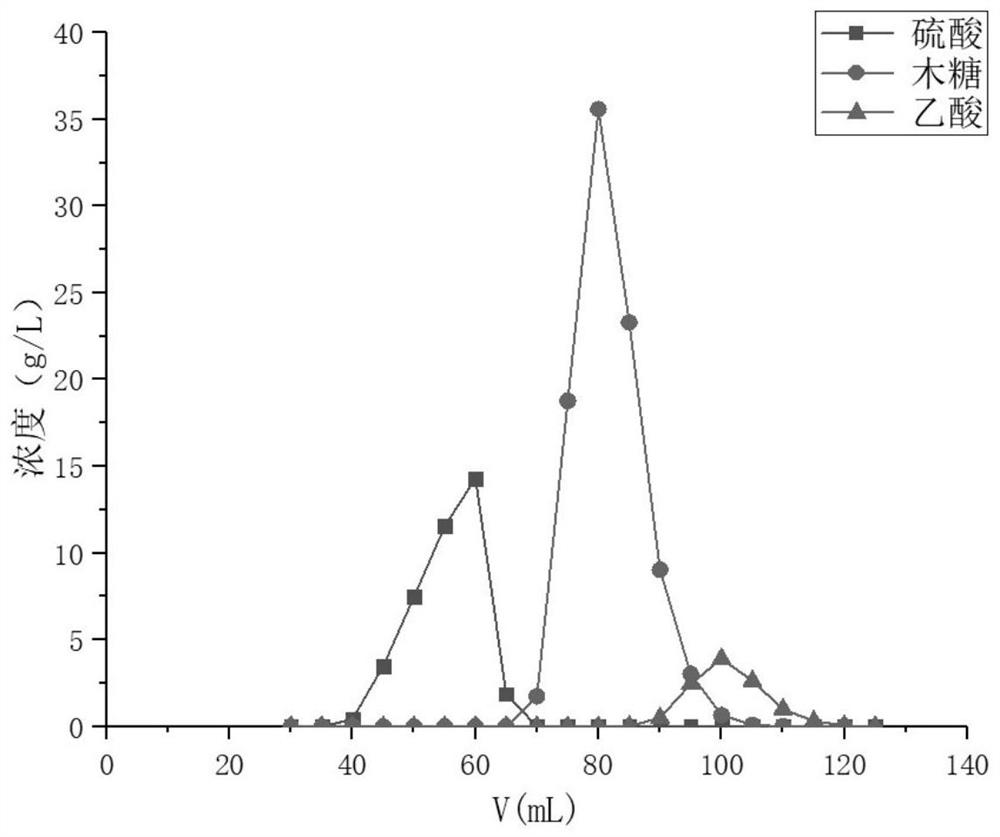

[0049] Embodiment 1: Investigate the separation experiment of three components of gel-type strongly acidic H-type cation exchange resin

[0050] Feed liquid to be separated: According to the concentration in Table 1, xylose, sulfuric acid, and acetic acid are compounded. In the resulting mixed aqueous solution, the concentration of xylose is 50g / L, the concentration of sulfuric acid is 20g / L, and the concentration of acetic acid is 6g / L. L.

[0051] Preparation of chromatographic column: Weigh a certain amount of gel-type strongly acidic H-type cation exchange resin and transfer it to a glass chromatographic column (column inner diameter is 2.2cm, and the filling height of gel-type strongly acidic H-type cation-exchange resin is 28cm) , and continuously flush the resin in the column with pure water to ensure that the resin is filled evenly until the resin height is constant.

[0052] Separation: At room temperature, the injection flow and elution flow are controlled by a peri...

Embodiment 2

[0054] Example 2: Investigate the separation experiment of the three components of the weakly polar adsorption resin

[0055] Feed liquid to be separated: Since there is no sulfuric acid component in the second-dimensional chromatographic column, xylose and acetic acid are compounded according to the concentration in Table 1. In the resulting mixed aqueous solution, the concentration of xylose is 50g / L, and the concentration of acetic acid is 50g / L. The concentration is 6g / L.

[0056] Preparation of chromatographic column: Weigh a certain amount of weakly polar adsorption resin that has been completely pretreated, and transfer it to a glass chromatography column (column inner diameter is 2.2cm, and the filling height of weakly polar adsorption resin is 28cm), and continuously clean it with pure water. Flush the resin in the column to ensure even resin packing until the resin height is constant.

[0057] Separation: At room temperature, the injection flow and elution flow are ...

Embodiment 3

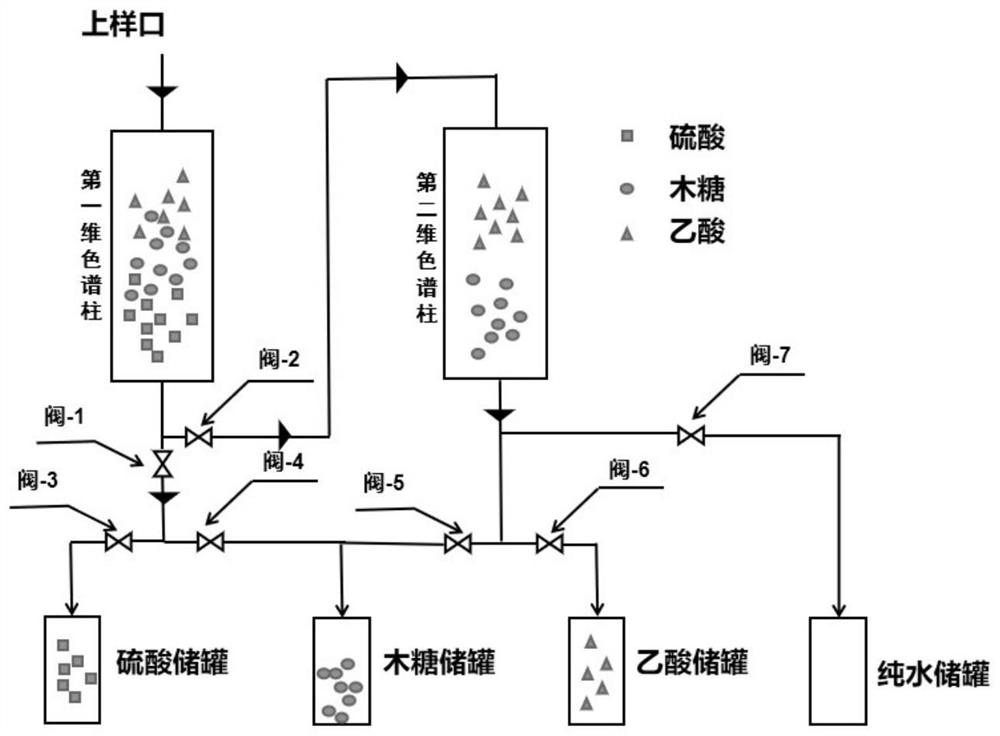

[0059] Example 3: Purification of sugar components in the compound liquid by quasi-two-dimensional chromatography

[0060] Feed liquid to be separated: with embodiment 1.

[0061] Set up the chromatographic column device: the first dimensional chromatographic column: fill a certain quality of gel-type strongly acidic H-type cation exchange resin into a glass chromatographic column (the inner diameter of the column is 2.2cm, and the filling height of the resin is 28cm), and rinse with pure water continuously Resin in the column, ensure that the resin is filled evenly until the resin height is constant; the second-dimensional chromatographic column: fill a certain quality of weakly polar adsorption resin in the glass chromatographic column (the inner diameter of the column is 1.8cm, and the resin filling height is 27cm), And continuously rinse the resin in the column with pure water to ensure that the resin is filled evenly until the resin height is constant; the first-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com