Hierarchical pore hydrotreating catalyst and preparation method thereof

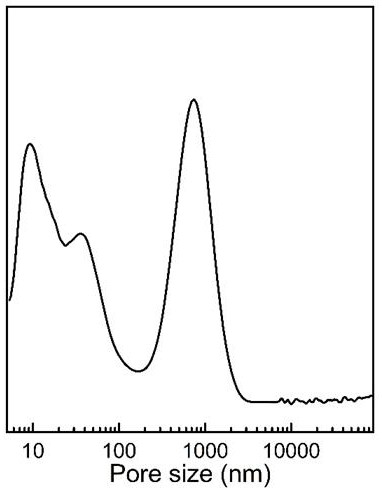

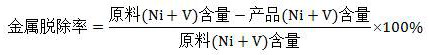

A hydrogenation treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of lack of multi-level pore structure, low demetallization performance of catalysts, and diffusion of residual oil macromolecules In order to achieve the effect of reducing diffusion resistance, rich pore structure, and good hydrodemetallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 300g of commercial pseudo-boehmite and record it as PA1 (the pore volume is 1.1mL / g, the specific surface area is 300m 2 / g), calcined at 500℃ for 2h in a muffle furnace to obtain the modified PA2-1. Weigh 110g PA1, 38g PA2-1, 44g pseudo-boehmite PB1 (pore volume 1.3mL / g, specific surface area 80m 2 / g, crystal size d(120) is 40nm) and 5g of scallop powder, stir and mix evenly. Add 245mL containing 6.5g / L NiO, 26.5g / L MoO 3 , 6.5g / L P 2 o 5 The Ni-Mo-P solution is kneaded into a plastic body, and then extruded into a four-leaf clover-shaped strip with a diameter of 1.3mm on an extruder. The wet strip was dried at 120°C for 12h, and kept at 500°C in a roasting furnace for 2h to obtain catalyst A1. The pore structure and metal loading of catalyst A1 are shown in Table 1.

Embodiment 2

[0027] Weigh 300g of commercial pseudo-boehmite and record it as PA1 (the pore volume is 1.1mL / g, the specific surface area is 300m 2 / g), calcined at 550°C for 2h in a muffle furnace to obtain the modified PA2-2. Weigh 95g PA1, 35g PA2-2, 58g pseudo-boehmite PB1 (pore volume 1.3mL / g, specific surface area 80m 2 / g, crystal size d(120) is 40nm) and 5g of scallop powder, stir and mix evenly. Add 235mL containing 6.8g / L NiO, 27.6g / L MoO 3 , 6.8g / L P 2 o 5 The Ni-Mo-P solution is kneaded into a plastic body, and then extruded into a four-leaf clover-shaped strip with a diameter of 1.3mm on an extruder. Dry the wet bar at 120°C for 12h, and keep the temperature at 550°C in a roasting furnace for 3h to obtain catalyst A2. The pore structure and metal loading of catalyst A2 are shown in Table 1.

Embodiment 3

[0029] Weigh 300g of commercial pseudo-boehmite and record it as PA1 (the pore volume is 1.1mL / g, the specific surface area is 300m 2 / g), calcined in a muffle furnace at 600°C for 2h to obtain the modified PA2-3. Weigh 103g PA1, 50g PA2-3, 35g pseudoboehmite PB1 (pore volume 1.3mL / g, specific surface area 80m 2 / g, crystal size d(120) is 40nm) and 5g of scallop powder, stir and mix evenly. Add 245mL containing 6.5g / L NiO, 26.5g / L MoO 3 , 6.5g / L P 2 o 5 The Ni-Mo-P solution is kneaded into a plastic body, and then extruded into a four-leaf clover-shaped strip with a diameter of 1.3mm on an extruder. The wet strip was dried at 120°C for 12 hours, and kept in a roasting furnace at 600°C for 3 hours to obtain catalyst A3. The pore structure and metal loading of catalyst A3 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com