A kind of small grain ssz-13 molecular sieve containing hierarchical pores and its synthesis method

A synthesis method and molecular sieve technology, which can be applied to molecular sieves and alkali exchange compounds, molecular sieve catalysts, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of hindering industrial production of SSZ-13 molecular sieve, hindering industrial production, increasing production costs, etc., Achieve the effect of good hydrothermal stability, good catalytic activity, and improved methanol conversion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, the preparation of the small grain SSZ-13 molecular sieve that contains hierarchical pores

[0046] (1) 100.0g 30% silica sol, 6.7g aluminum sulfate octadecahydrate, 50.0g 25% N,N,N-trimethyl-1-adamantyl ammonium hydroxide aqueous solution, 0.6g solid NaOH and 15.9g Ionized water was mixed and stirred thoroughly to obtain a slurry.

[0047] (2) Add 2 g of 36.5% hydrochloric acid and 0.5 g of SSZ-13 molecular sieve seed crystals to the slurry in step (1), and stir evenly to obtain the material to be crystallized.

[0048] (3) Transfer the material to be crystallized in step (2) into a crystallization kettle, control the crystallization at 200°C for 20 hours, and then wash, filter, dry, and roast the crystallized slurry to obtain sample 1 #.

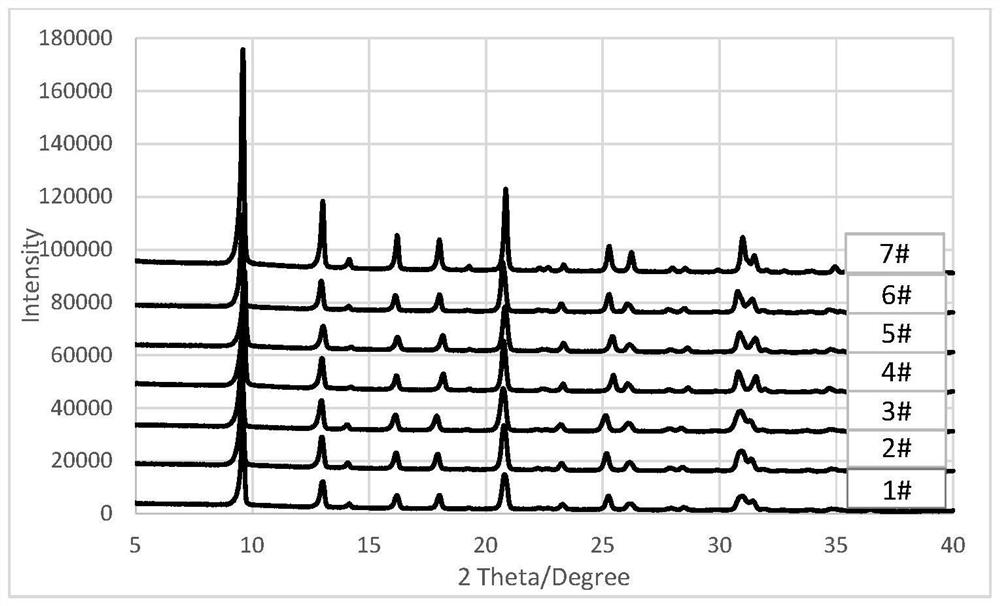

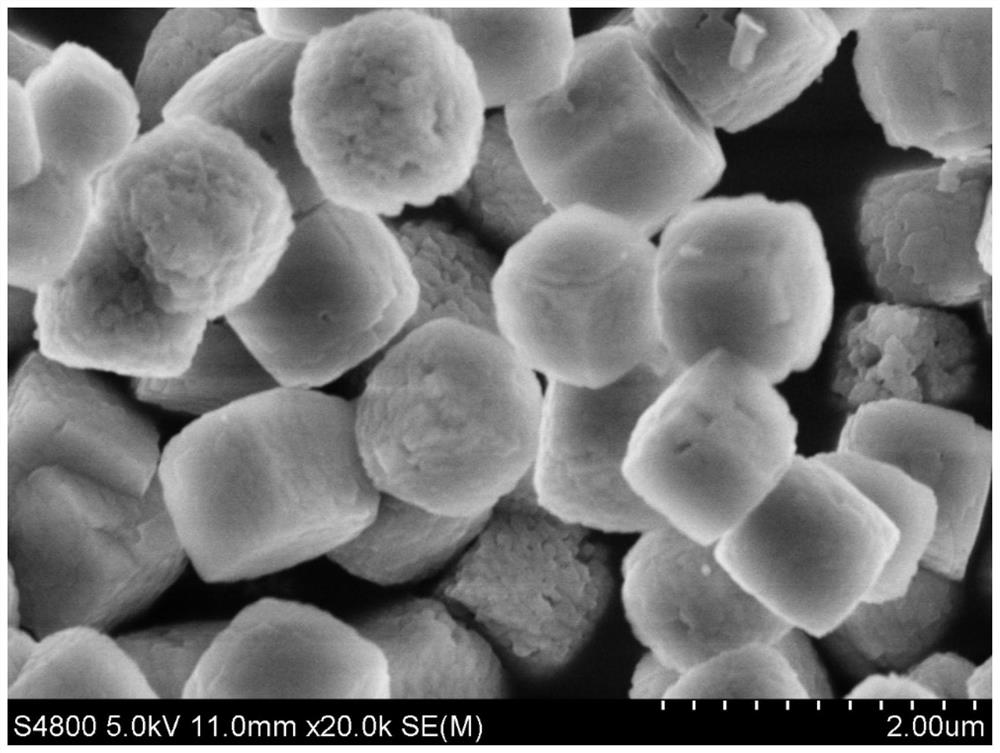

[0049] Carry out XRD analysis and electron microscope scanning on sample 1#, the XRD picture is as follows figure 1 As shown, the SEM image is shown in figure 2 shown.

[0050] from figure 2 It can be seen that...

Embodiment 2

[0053] Embodiment 2, the preparation of the small grain SSZ-13 molecular sieve that contains hierarchical pores

[0054] (1), 10.0g 30% silica sol, 6.7g aluminum sulfate octadecahydrate, 9.0g 25% N,N,N-trimethyl-1-adamantyl ammonium hydroxide aqueous solution, 8.0g solid NaOH and 50.0g Deionized water was mixed and stirred thoroughly to obtain a slurry.

[0055] (2) Add 3.0 g of n-butylammonium chloride and 2.0 g of SAPO-34 molecular sieve seed crystals to the slurry in step (1), and stir evenly to obtain the material to be crystallized.

[0056] (3), transfer the material to be crystallized in step (2) into a crystallization kettle, control the crystallization at 180°C for 24 hours, and then wash, filter, dry, and roast the slurry after crystallization to obtain a sample 2#.

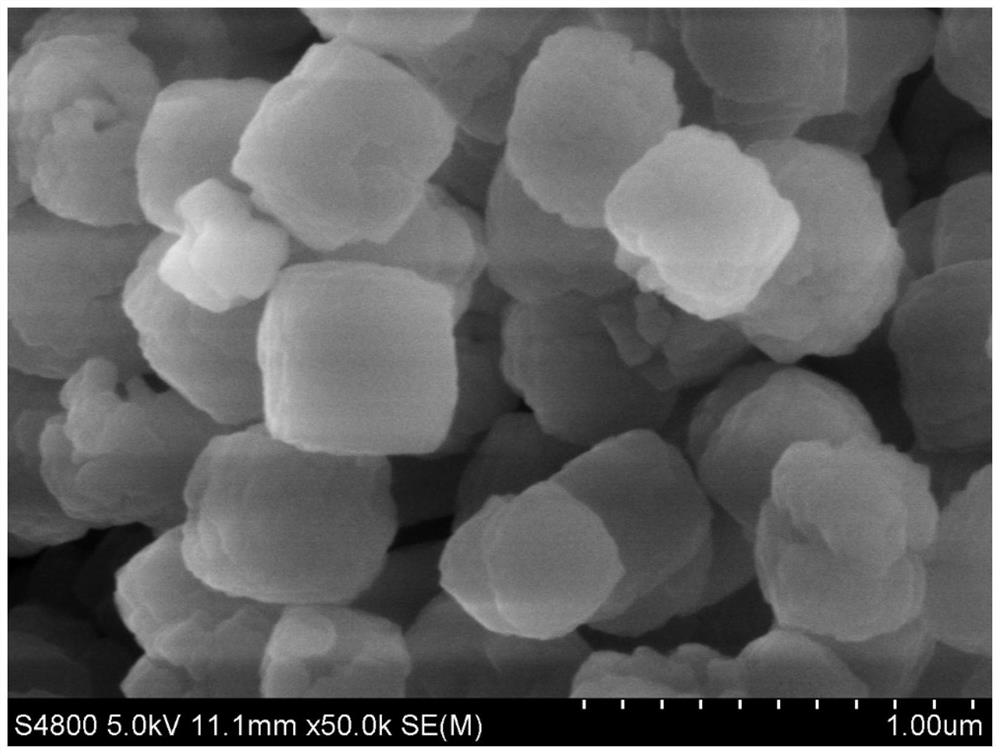

[0057] Carry out XRD analysis and electron microscope scanning on sample 2#, the XRD picture is as follows figure 1 As shown, the SEM image is shown in image 3 shown.

[0058] from image 3 It ca...

Embodiment 3

[0061] Embodiment 3, the preparation of the small grain SSZ-13 molecular sieve that contains hierarchical pores

[0062] (1), 40.1g of white carbon black, 5.1g of pseudoboehmite, 200.2g of 25% N,N,N-trimethyl-1-adamantane ammonium hydroxide aqueous solution, 27.9g of solid NaOH and 300.0g of Ionized water was mixed and stirred thoroughly to obtain a slurry.

[0063] (2) Add 5 g of hexachlorocyclohexane and 3 g of SAPO-34 molecular sieve seed crystals to the slurry in step (1), and stir evenly to obtain the material to be crystallized.

[0064] (3), transfer the material to be crystallized in step (2) into a crystallization kettle, control the crystallization at 160°C for 48 hours, then wash, filter, dry, and roast the slurry after crystallization to obtain a sample 3#.

[0065] Carry out XRD analysis and electron microscope scanning on sample 3#, the XRD picture is as follows figure 1 As shown, the SEM image is shown in Figure 4 shown.

[0066] from Figure 4 It can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com