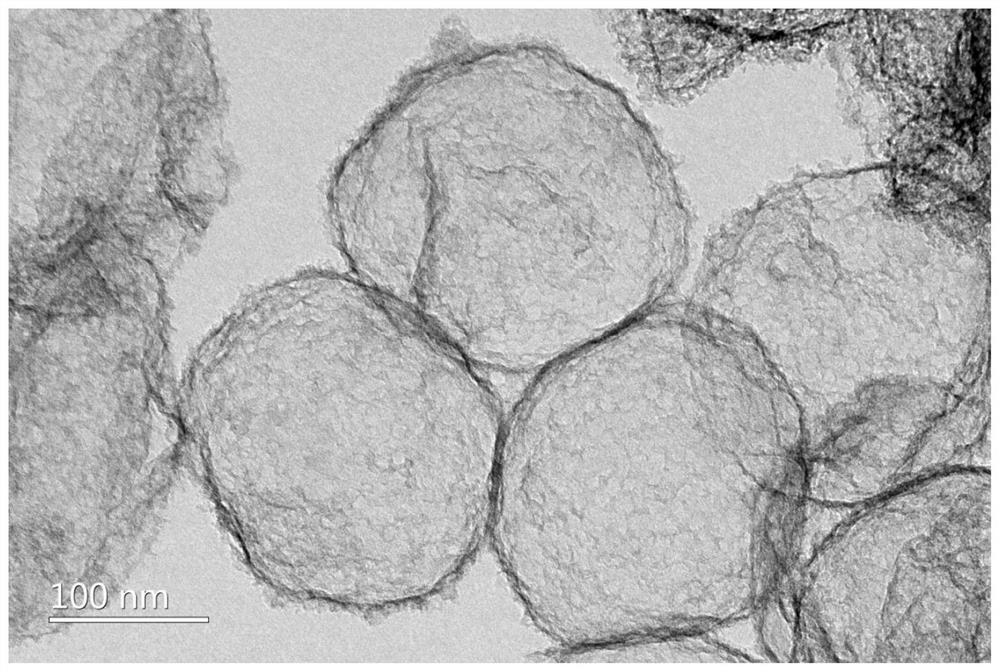

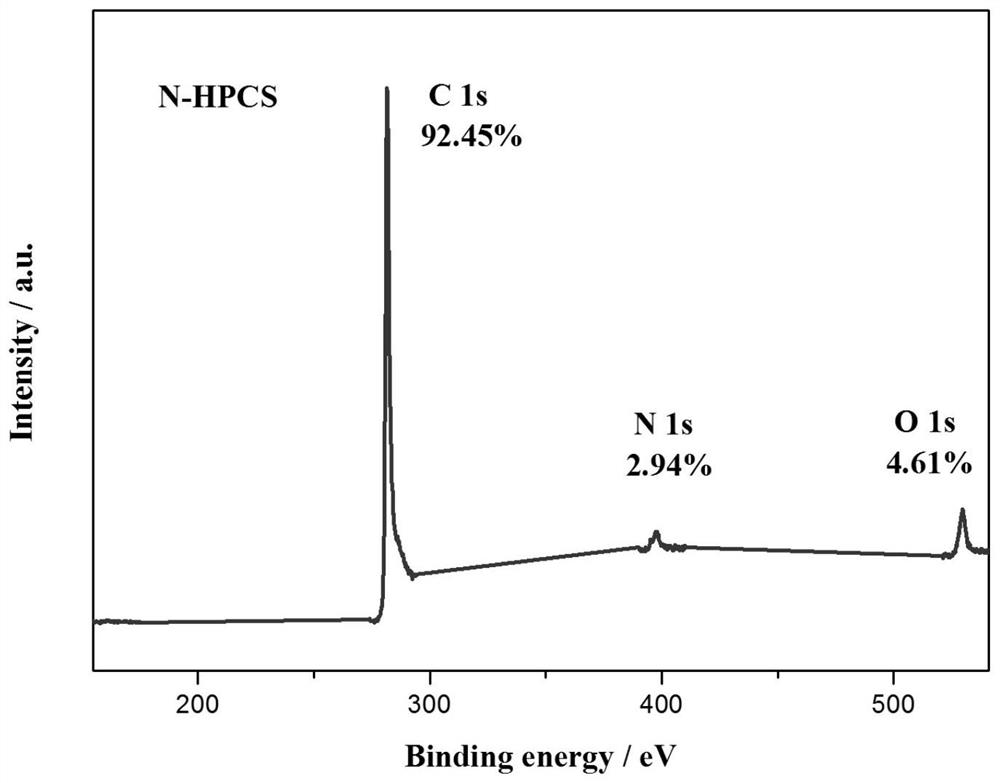

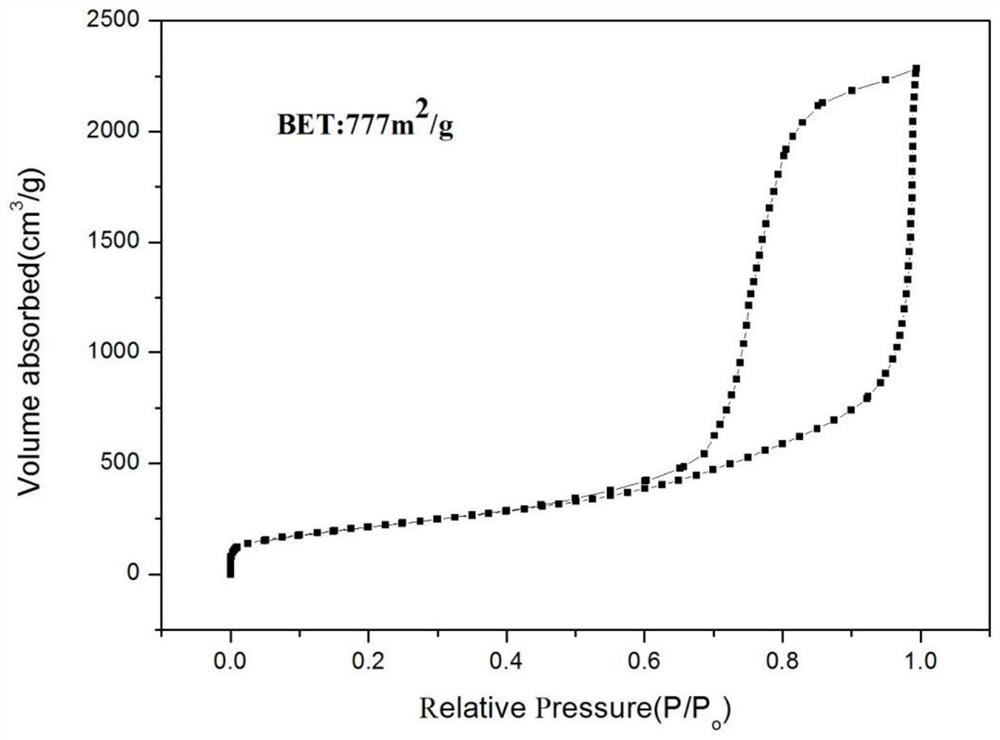

Nitrogen-doped hierarchical porous carbon spheres and preparation method thereof

A nitrogen-doped, multi-level pore technology, applied in structural parts, electrolytic components, electrolytic processes, etc., can solve problems that limit large-scale applications, achieve good electrocatalytic activity, and facilitate rapid diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing nitrogen-doped hierarchically porous carbon spheres, the specific steps are as follows:

[0022] Step 1: Prepare polystyrene microspheres (PS) with a diameter of 200 nm by soap-free emulsion polymerization. 2gPS was dispersed in 40mL concentrated sulfuric acid with a mass fraction of 98% by ultrasonic, and stirred at 40℃ for 12h. After the reaction was completed, it was washed with deionized water until it was neutral. The obtained sulfonated PS microspheres were dispersed in water with a solid content of 4 mg / mL, which was recorded as SPS.

[0023] Step 2: 2.8 g of melamine and 5.3 mL of formaldehyde solution with a mass fraction of 37% were mixed and stirred at 60° C. to obtain a transparent solution.

[0024] The third step: put the polyvinyl alcohol solution with a mass fraction of 5% in the flask, and add 25 mL of SPS, 5 mL of silicon dioxide and the prepolymer obtained in the second step in sequence. Then add glacial acetic acid to adjust...

Embodiment 2

[0027] A method for preparing nitrogen-doped hierarchically porous carbon spheres, the specific steps are as follows:

[0028] Step 1: Prepare polystyrene microspheres (PS) with a diameter of 200 nm by soap-free emulsion polymerization. 2gPS was dispersed in 40mL concentrated sulfuric acid with a mass fraction of 98% by ultrasonic, and stirred at 40℃ for 8h. After the reaction was completed, it was washed with deionized water until it was neutral. The obtained sulfonated PS microspheres were dispersed in water with a solid content of 4 mg / mL, which was recorded as SPS.

[0029] Step 2: 2 g of melamine and 5 mL of formaldehyde solution with a mass fraction of 37% were mixed and stirred at 60° C. to obtain a transparent solution.

[0030] The third step: put the polyvinyl alcohol solution with a mass fraction of 5% in the flask, and add 25 mL of SPS, 5 mL of silicon dioxide and the prepolymer obtained in the second step in sequence. Then add glacial acetic acid to adjust the ...

Embodiment 3

[0033] A method for preparing nitrogen-doped hierarchically porous carbon spheres, the specific steps are as follows:

[0034] Step 1: Prepare polystyrene microspheres (PS) with a diameter of 200 nm by soap-free emulsion polymerization. 2gPS was dispersed in 40mL concentrated sulfuric acid with a mass fraction of 98% by ultrasonic, and stirred at 40℃ for 8h. After the reaction was completed, it was washed with deionized water until it was neutral. The obtained sulfonated PS microspheres were dispersed in water with a solid content of 2 mg / mL, which was recorded as SPS.

[0035] The second step: 2.5 mL of melamine and 4.5 mL of formaldehyde solution with a mass fraction of 37% were mixed and stirred at 60° C. to obtain a transparent solution.

[0036] The third step: put the polyvinyl alcohol solution with a mass fraction of 5% in the flask, and add 25 mL of SPS, 5 mL of silicon dioxide and the prepolymer obtained in the second step in sequence. Then add glacial acetic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com