Multi-shell MOF-polyCOF core-shell structure composite catalytic material and preparation method thereof

A core-shell structure and catalytic material technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, hydrolysis preparation, etc., can solve difficult adsorption substrates, restrict catalytic reactions, conversion rates and selection Low sex and other problems, to achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Using 2,5-diethoxyhydroquinone (DTH) dimer and PEG bridge (DTH-dimer-x, x = PEG molecular weight) as a monomer, pass PolyCOF obtained by interfacial polycondensation of 1,3,5-tris(4'-formylphenyl)benzene and dth-dimer x, specifically: add 0.0375 mmol of DTH-dimer-42 to a beaker, dissolve in 1.0 ml 1,4-dioxane solution to obtain solution 1; 0.025mmol of 1,3,5-tri(4'-formylphenyl)benzene and 0.525ml of CHCOOH solution in 3mL mesitylene Solution 2 was obtained; mixed solutions 1 and 2 were stirred at room temperature for 48 hours to obtain polyCOFs mother liquor.

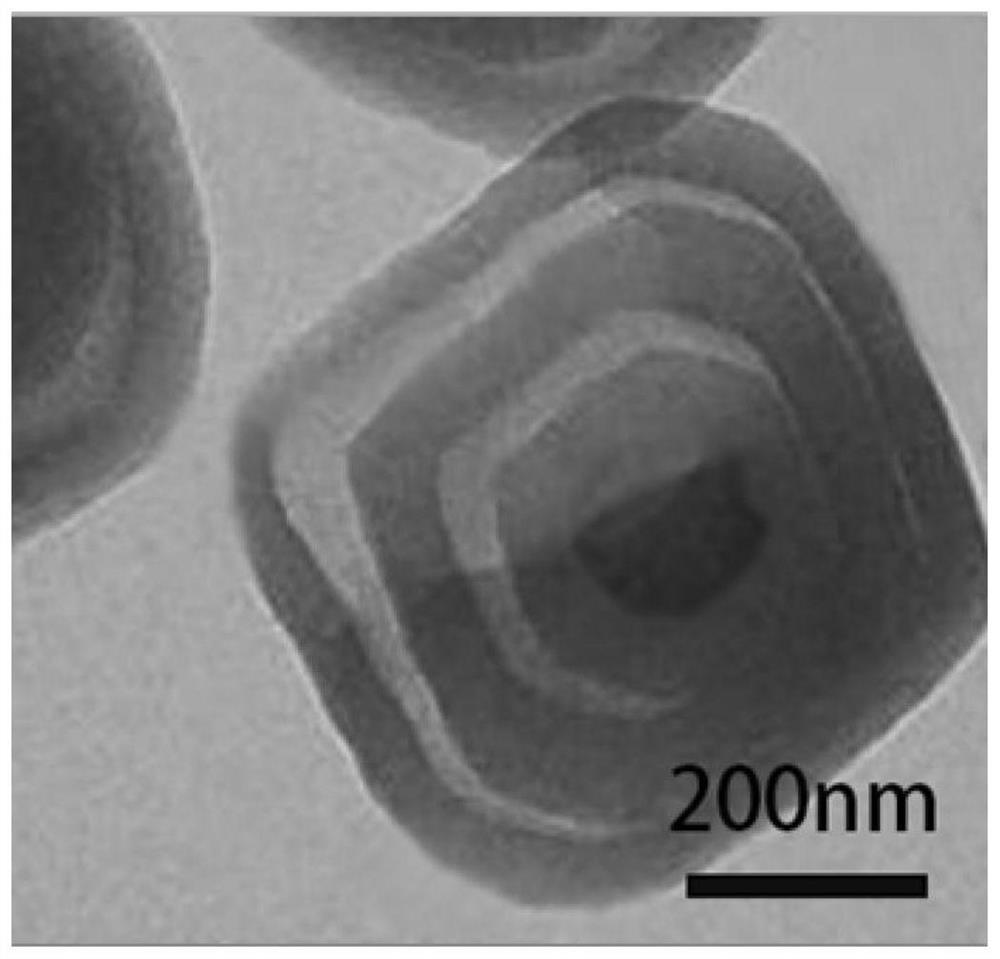

[0032] (2) Coating the first MOF shell on the polyCOF, specifically: the polyCOF prepared in step 1 is used as the core to disperse the Fe(NO 3 ) 3 9H 2 In a mixed solution of O (0.40g, 1.0mmol), organic ligand (Formula 1) (0.11g, 0.66mmol) and 10mL of water, stir well for 5 minutes until uniform, then transfer to a polytetrafluoroethylene-lined reaction kettle , and then reacted at 180°C for 4 hours, wa...

Embodiment 2

[0051] (1) Using 2,5-diethoxyhydroquinone (DTH) dimer and PEG bridge (DTH-dimer-x, x = PEG molecular weight) as a monomer, pass PolyCOF obtained by interfacial polycondensation of 1,3,5-tris(4'-formylphenyl)benzene and dth-dimer x, specifically: add 0.0375 mmol of DTH-dimer-42 to a beaker, dissolve in 1.0 ml 1,4-dioxane solution to obtain solution 1; 0.025mmol of 1,3,5-tri(4'-formylphenyl)benzene and 0.525ml of CHCOOH solution in 3mL mesitylene solution 2; mixed solutions 1 and 2, stirred at room temperature for 48 hours, and obtained polyCOFs mother liquor

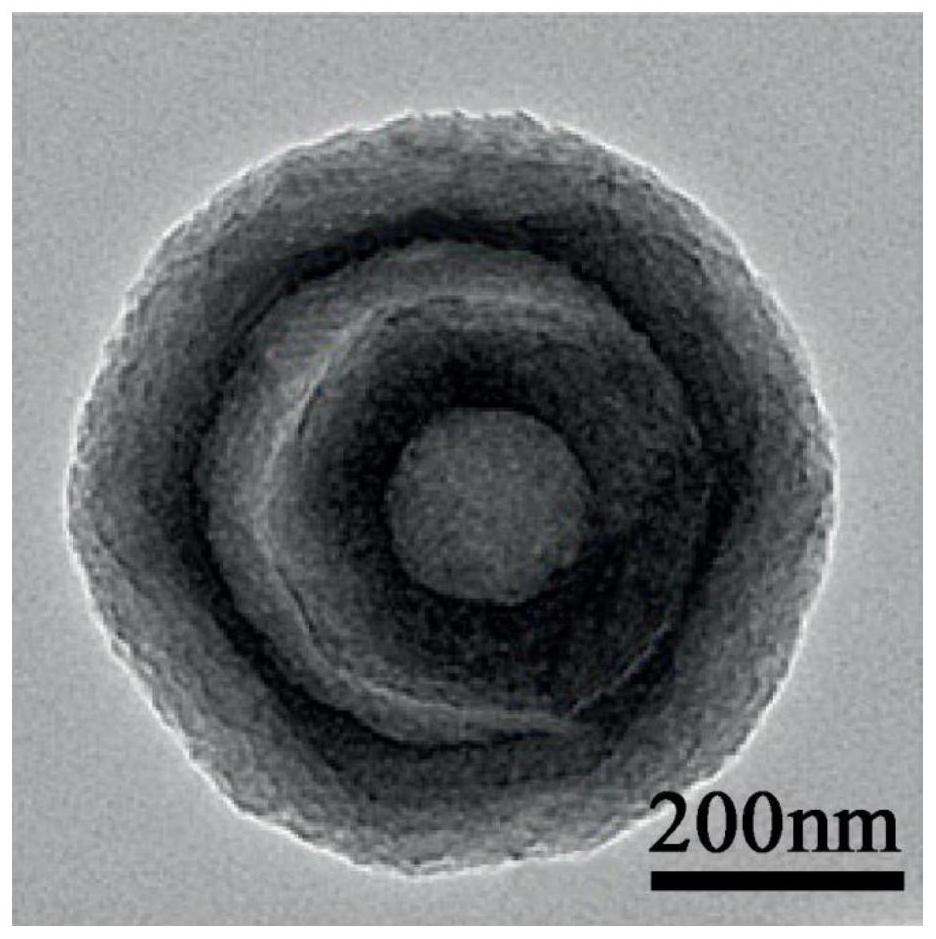

[0052] (2) Coating the first MOF shell on the polyCOF, specifically: dispersing the polyCOF prepared in step 1 as the core into Cr(NO 3 ) 3 9H 2 O (0.40g, 1.0mmol), organic ligand (Formula 2) (0.11g, 0.66mmol) and 10mL water mixed solution, stirred for 5 minutes until uniform, then transferred to a polytetrafluoroethylene-lined reactor, Then react at 180°C for 4 hours, wash twice with DMF and deionized water respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com