Glass fiber reinforced plastic fan shell and preparation method thereof

A technology of glass fiber reinforced plastics and shells, applied in chemical instruments and methods, glass/slag layered products, and other household appliances, etc., can solve the problem of hardness, tensile strength, poor acid and alkali corrosion resistance, and poor acid and alkali corrosion resistance , low hardness of the fan casing, etc., to achieve the effect of good tensile strength and acid and alkali corrosion resistance, beautiful appearance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

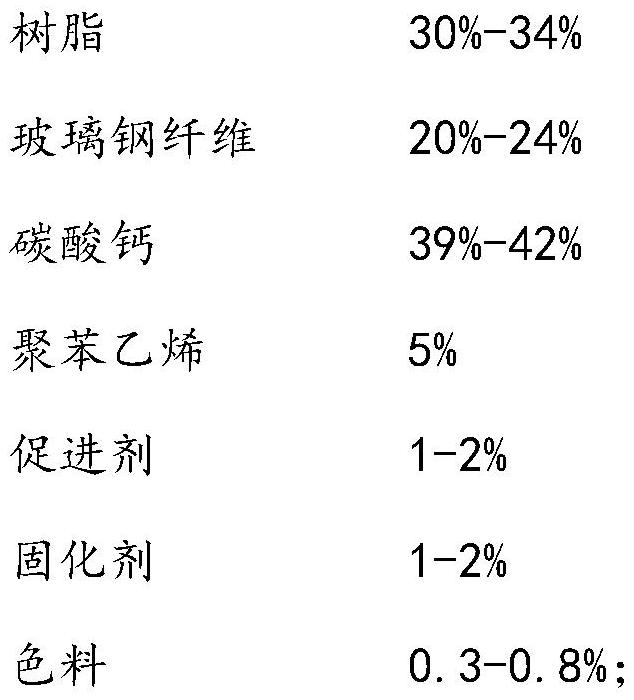

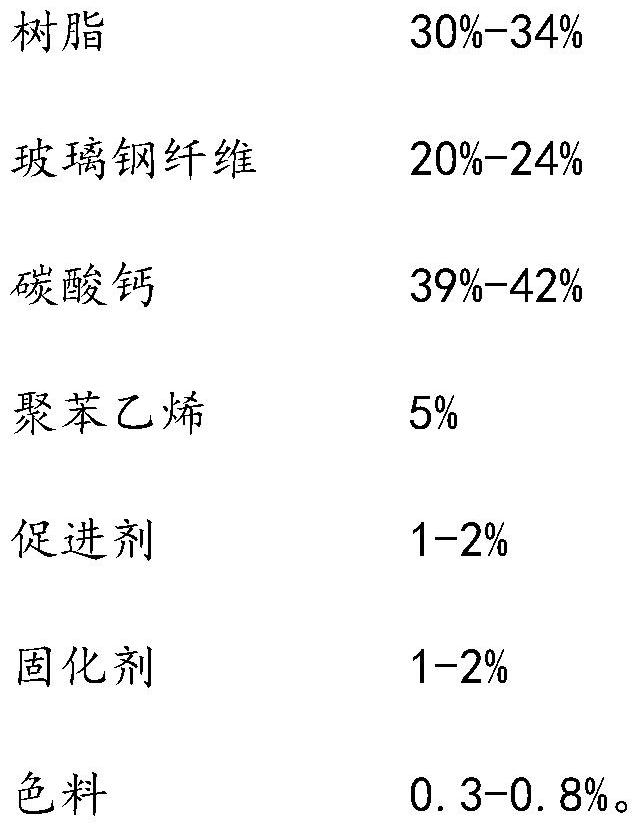

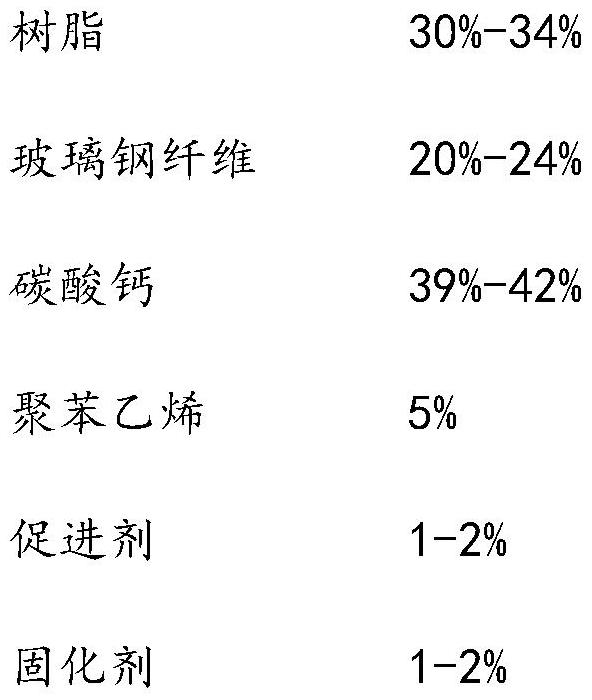

preparation example Construction

[0051] This embodiment also provides a method for preparing a FRP fan casing, including the following steps:

[0052] Step 1, laying a layer of PE film on the conveyor belt of the sheet machine;

[0053] Step 2: Stir the resin, calcium carbonate, polystyrene, accelerator, curing agent, and colorant according to the weight percentage into a paste, then roll it into a resin sheet with the inner roller of the sheet machine, and spread it on the PE film;

[0054] Step 3: Sprinkle glass fiber evenly on the first layer of sheet, then cover with a layer of resin sheet made of resin, calcium carbonate, polystyrene, and stick a layer of PE film on top of the sheet;

[0055] Sprinkle glass fiber evenly on the sheet, so that the glass fiber is distributed randomly on the surface of the sheet, so that the shell has good tensile strength and tensile breaking strain in all directions.

[0056] Step 4: Roll and compact the glass fiber reinforced plastic raw material sheet through the inner ...

Embodiment 1

[0062] In this embodiment, a glass fiber reinforced plastic fan casing, its manufacturing process includes the following steps:

[0063] Step 1, laying a layer of PE film on the conveyor belt of the sheet machine;

[0064] Step 2, prepare 30 parts of resin, 39 parts of calcium carbonate, 5 parts of polystyrene, 1 part of accelerator, 1 part of curing agent and 0.3 part of coloring material in parts by weight, stir into a paste, and then use the inner roller of the sheet material machine Rolled into a resin sheet, spread on the PE film;

[0065] Step 3: Sprinkle 10 parts of glass fiber evenly on the first layer of sheet material, and then cover a layer of resin sheet material made of resin, calcium carbonate, polystyrene, accelerator, curing agent and coloring material. Paste a layer of PE film on it;

[0066] Step 4: Roll and compact the glass fiber reinforced plastic raw material sheet through the inner roller of the sheet material machine.

[0067] Wherein, the thickness ...

Embodiment 2

[0070] In this embodiment, a glass fiber reinforced plastic fan casing, its manufacturing process includes the following steps:

[0071] Step 1, laying a layer of PE film on the conveyor belt of the sheet machine;

[0072] Step 2, prepare 34 parts of resin, 42 parts of calcium carbonate, 5 parts of polystyrene, 2 parts of accelerator, 2 parts of curing agent and 0.8 part of coloring material by weight percentage, stir into a paste, and then grind with the inner roller of the sheet material machine Pressed into a resin sheet, spread on the PE film;

[0073] Step 3: Sprinkle 12 parts of glass fiber evenly on the first layer of sheet material, and then cover a layer of resin sheet material made of resin, calcium carbonate, polystyrene, accelerator, curing agent and colorant. Paste a layer of PE film on it;

[0074] Step 4: Roll and compact the glass fiber reinforced plastic raw material sheet through the inner roller of the sheet material machine.

[0075] Wherein, the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com