Solid waste-based composite lithium slag ultra-fine admixture as well as preparation method and application thereof

An admixture and complex lithium technology, applied in grain processing, cement production, etc., can solve the problems of inefficiency, improper matching treatment, low utilization rate of solid waste-based resources, etc., to enhance frost resistance and weather resistance, The effect of reducing porosity and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

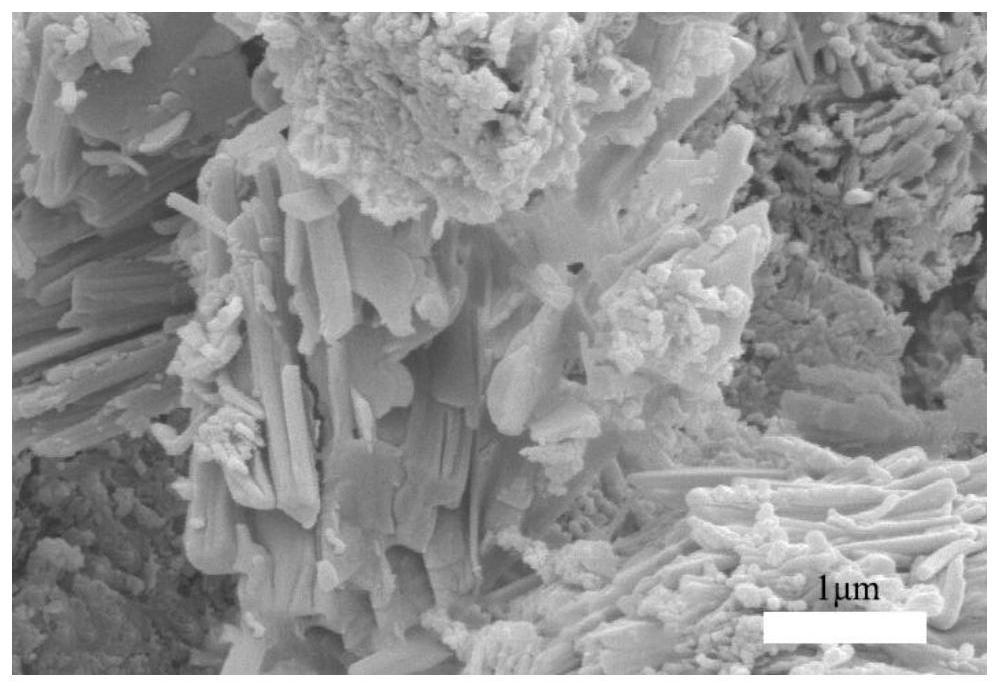

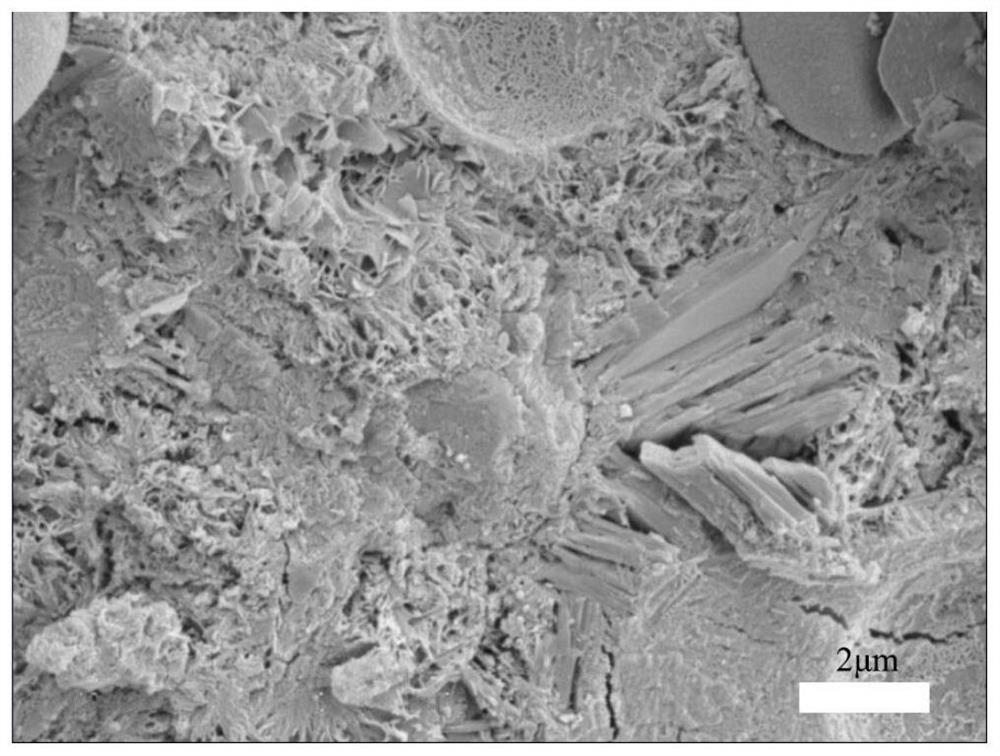

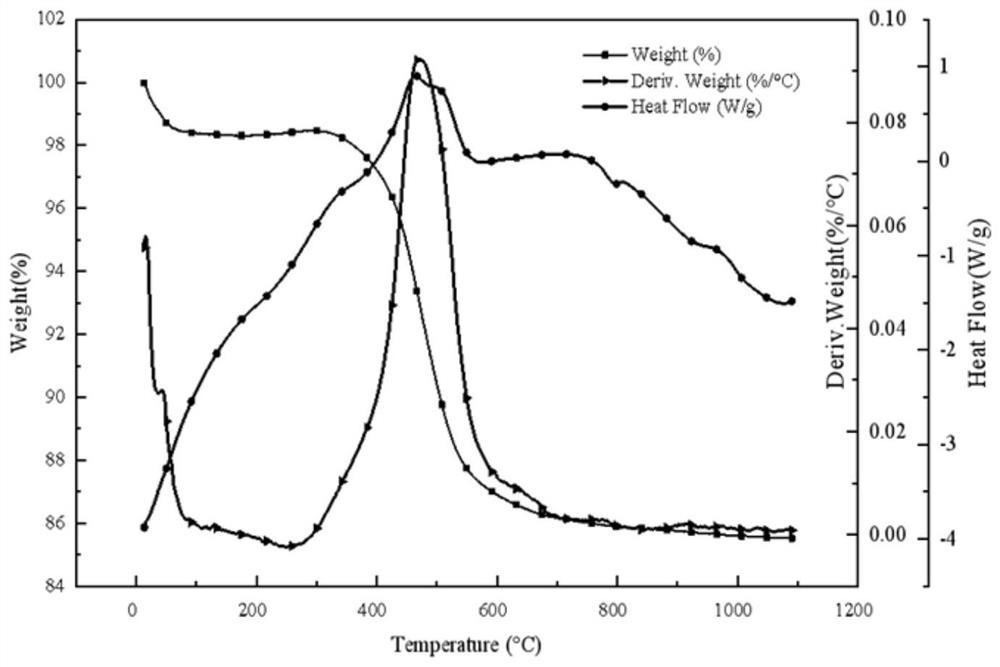

Method used

Image

Examples

Embodiment 1

[0035] The solid waste-based composite lithium slag ultra-fine admixture of this embodiment, the raw materials include lithium slag, steel slag, coal gangue and fly ash with a mass percentage of 85%: 7%: 5%: 3%. 0.2% of the liquid activator of the total mass of cement raw materials and admixtures in the cement mortar; the liquid activator has a multi-solid waste synergistic excitation function, and the composition of each raw material by weight is:

[0036]

[0037]

[0038] The mass percentages of the main chemical components in lithium slag, steel slag, coal gangue and fly ash used in this example are shown in Tables 1 to 4.

[0039] Table 1 Lithium slag main chemical composition (wt%)

[0040]

[0041] Table 2 Steel slag main chemical composition (wt%)

[0042]

[0043] Table 3 main chemical composition of coal gangue (wt%)

[0044]

[0045] Table 4 main chemical composition of fly ash (wt%)

[0046]

[0047] The preparation method of the solid waste-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com