High-temperature composite NTC (Negative Temperature Coefficient) resistance material based on metal oxide as well as preparation method and application thereof

A technology of resistive materials and oxides, which is applied to resistors with negative temperature coefficients, grain processing, lighting and heating equipment, etc. The effect of avoiding dust scattering and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

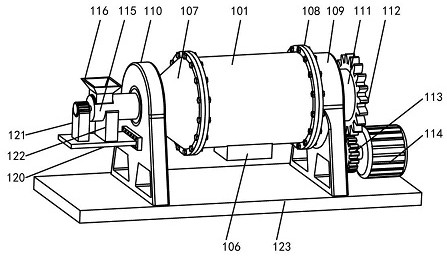

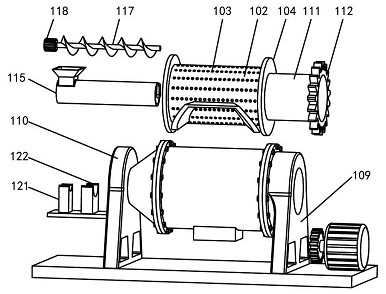

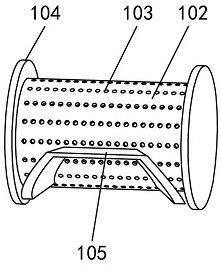

Image

Examples

Embodiment 1

[0036] A high-temperature composite NTC resistance material based on metal oxides, comprising the following components in parts by mass: 15 parts of metal oxides, 10 parts of grinding liquid, 0.1 parts of sintering aid, 1 part of binder and 20 parts of solvent, wherein, according to In terms of mass percentage, the metal oxide is composed of 35% cobalt tetroxide, 25% chromium oxide, 15% nickel oxide, 8% cuprous oxide, 12% manganese dioxide and 5% magnesium oxide. The grinding fluid is 15% ethanol aqueous solution; the sintering aid is Bi 2 o 3 -B 2 o 3 ; The solvent is propyl acetate. The binder includes at least one of polyvinyl alcohol, carboxymethyl cellulose, starch and dextrin.

[0037] The above-mentioned preparation method based on metal oxide high temperature composite NTC resistance material comprises the following steps:

[0038] S1, according to the mass percentage, weigh tricobalt tetroxide, dichromium trioxide, nickel trioxide, cuprous oxide, manganese dioxid...

Embodiment 2

[0042] The difference from Example 1 is that the metal oxide-based high-temperature composite NTC resistance material of this example includes the following components by mass: 24 parts of metal oxide, 12 parts of grinding liquid, 0.5 parts of sintering aid, binder 2 parts and 30 parts of solvent.

[0043] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0045] The difference from Example 1 is that the metal oxide-based high-temperature composite NTC resistance material of this example includes the following components by mass: 30 parts of metal oxide, 15 parts of grinding liquid, 1 part of sintering aid, binder 4 parts and 40 parts of solvent.

[0046] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com