Synthesis process of 2, 2 '-dichloroazobenzene

A technology of dichloroazobenzene and synthesis process, applied in the direction of organic chemistry, etc., can solve the problems of high labor intensity, large zinc powder consumption, complicated operation, etc., and achieve the goal of increasing production rate, improving production efficiency, and simple synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

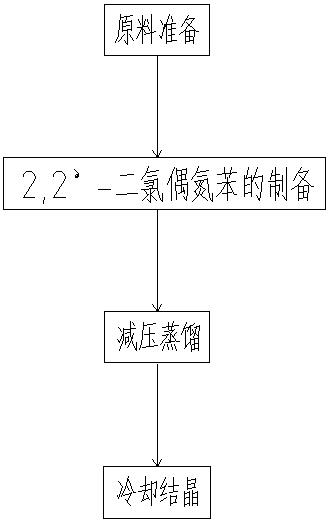

[0019] A kind of 2,2'-dichloroazobenzene synthesis technique, concrete synthesis technique is as follows:

[0020] S1: Preparation of raw materials: using 2-chloronitrobenzene as raw material, mix 2-chloronitrobenzene and isopropanol solution to form a mixed solution, and the content of 2-chloronitrobenzene in the mixed solution is 25% ; With alumina as the adsorbent, the ruthenium catalyst is adsorbed by alumina;

[0021] S2: Preparation of 2,2'-dichloroazobenzene: Put the ruthenium catalyst adsorbed by 5kg alumina into the fixed bed reactor, and pass the booster pump to the fixed bed reactor at a rate of 10ml / min Continuously feed 100 kg of a mixed solution with a 25% 2-chloronitrobenzene content; at the same time, feed hydrogen gas into the solution in the fixed-bed reactor, and heat the fixed-bed reactor to 125°C;

[0022] S3: Distillation under reduced pressure: open the pressure relief valve of the fixed bed reactor to release the pressure of the fixed bed reactor, then...

Embodiment 2

[0025] A kind of 2,2'-dichloroazobenzene synthesis technique, concrete synthesis technique is as follows:

[0026] S1: Preparation of raw materials: using 2-chloronitrobenzene as raw material, mix 2-chloronitrobenzene and isopropanol solution to form a mixed solution, and the content of 2-chloronitrobenzene in the mixed solution is 25% ; With alumina as the adsorbent, the ruthenium catalyst is adsorbed by alumina;

[0027] S2: Preparation of 2,2'-dichloroazobenzene: Put the ruthenium catalyst adsorbed by 5kg alumina into the fixed bed reactor, and pass the booster pump to the fixed bed reactor at a rate of 10ml / min Continuously feed 100 kg of a mixed solution with a 2-chloronitrobenzene content of 30%; at the same time, feed hydrogen into the solution in the fixed-bed reactor, and heat the fixed-bed reactor to 125°C;

[0028] S3: Distillation under reduced pressure: open the pressure relief valve of the fixed bed reactor to release the pressure of the fixed bed reactor, then ...

Embodiment 3

[0031] A kind of 2,2'-dichloroazobenzene synthesis technique, concrete synthesis technique is as follows:

[0032] S1: Preparation of raw materials: using 2-chloronitrobenzene as raw material, mix 2-chloronitrobenzene and isopropanol solution to form a mixed solution, and the content of 2-chloronitrobenzene in the mixed solution is 25% ; With alumina as the adsorbent, the ruthenium catalyst is adsorbed by alumina;

[0033] S2: Preparation of 2,2'-dichloroazobenzene: Put the ruthenium catalyst adsorbed by 5kg alumina into the fixed bed reactor, and pass the booster pump to the fixed bed reactor at a rate of 10ml / min Continuously feed 100 kg of a mixed solution with a 2-chloronitrobenzene content of 35%; at the same time, feed hydrogen into the solution in the fixed-bed reactor, and heat the fixed-bed reactor to 125°C;

[0034] S3: Distillation under reduced pressure: open the pressure relief valve of the fixed bed reactor to release the pressure of the fixed bed reactor, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com