Temperature-resistant modified natural polymer drilling fluid

A technology of natural macromolecule and drilling fluid, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of not discussing the optimization of antioxidants and stabilizers, and achieve the effect of maintaining aesthetics and improving temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

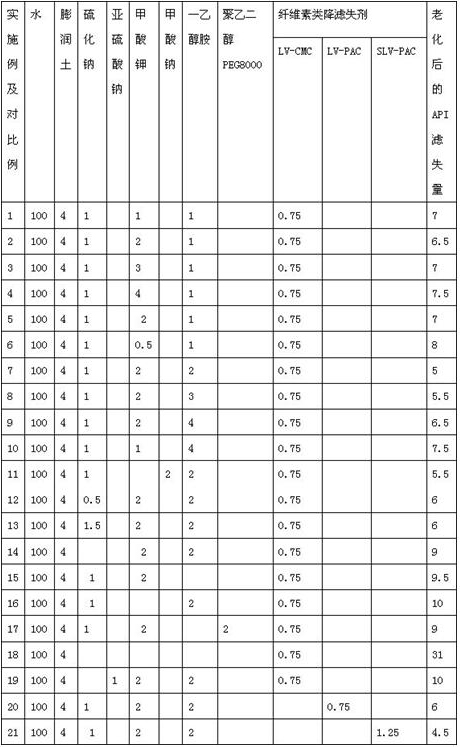

[0033] According to 100 parts of water, 1 part of sodium sulfide, 1 part of sodium formate, 1 part of monoethanolamine, 4 parts of bentonite, 0.75 parts of low-viscosity carboxymethyl cellulose purchased in the market, after stirring at high speed for 20 minutes, aging at 150 degrees for 16 hours, measure The results of the drilling fluid fluid loss after aging are shown in Table 1 below.

Embodiment 2

[0035] According to 100 parts of water, 1 part of sodium sulfide, 2 parts of sodium formate, 1 part of monoethanolamine, 4 parts of bentonite, and 0.75 parts of low-viscosity carboxymethyl cellulose purchased in the market, after stirring at high speed for 20 minutes, aging at 150 degrees for 16 hours, using The same method as in Example 1 was used to measure the fluid loss of the aging drilling fluid, and the results are shown in Table 1 below.

[0036] In Table 1, the configuration methods and performance tests of the drilling fluids in Examples 3-11, 18-19 and Comparative Examples 12-17 are the same as those in Example 1, see Table 1.

[0037] In the comparative example, one or more of formate, monoethanolamine and sodium sulfide were missing. Or in the comparative example, monoethanolamine is replaced by PEG8000, or sodium sulfide is replaced by sodium sulfite.

[0038]

[0039] surface Drilling fluid main component content and performance after aging in each embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com