Preheat treatment process for super-strong high-toughness carburizing steel bar and forge piece

A technology for preparatory heat treatment and carburizing steel, applied in the field of material processing, can solve the problems that cannot be completely eliminated, weakened tissue inheritance, reduced α phase supersaturation and hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Processing object: super-strong and high-toughness carburizing steel forged bar with a diameter of 160mm

[0034] 2. Preparatory heat treatment process

[0035] (1) Primary high-temperature tempering: the bar is heated up with the furnace, heated to 680°C, held for 20 hours, cooled to 300°C in the furnace, and then air-cooled to room temperature.

[0036] (2) Incomplete annealing: The bar is heated up with the furnace, heated to 950°C, held for 3 hours, cooled to 500°C in the furnace, and air-cooled to room temperature.

[0037] (3) Secondary high-temperature tempering: the bar is heated up with the furnace, heated to 680°C, held for 20 hours, cooled to 300°C in the furnace, and then air-cooled to room temperature.

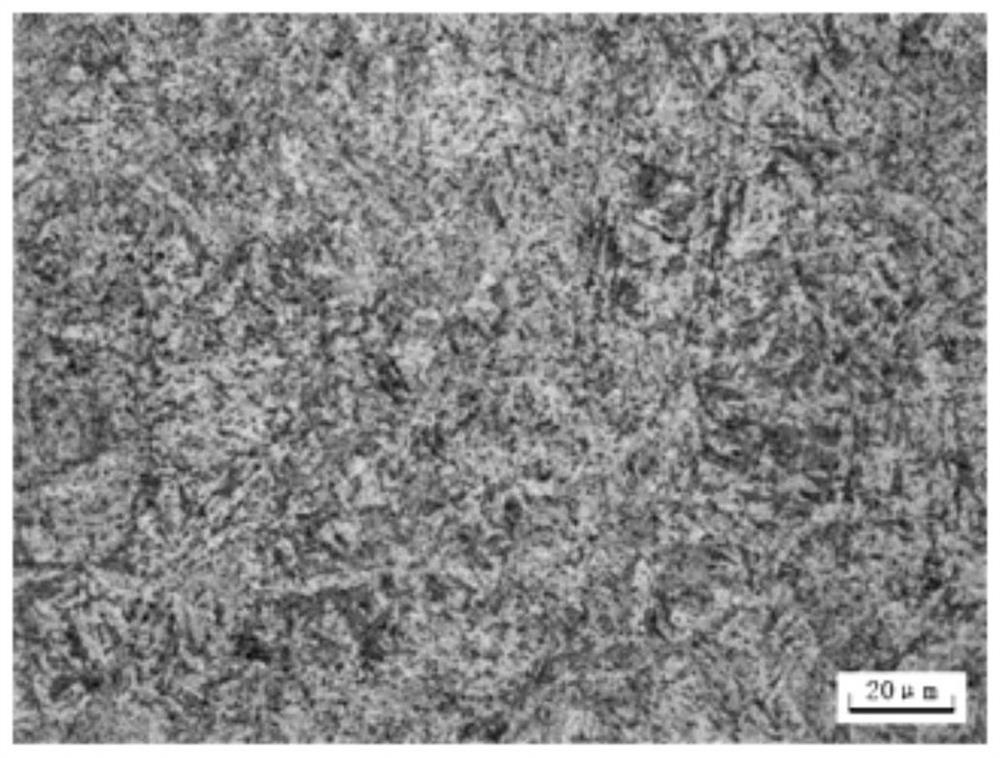

[0038] 3. Microstructure and hardness

[0039] Rod microstructure see figure 1 , is a granular carbide dispersed on the tempered sorbite matrix, with a hardness of 31.5HRC.

Embodiment 2

[0041] 1. Processing object: super strong and high toughness carburized steel bevel gear forgings

[0042] 2. Preparatory heat treatment process

[0043] (1) Primary high-temperature tempering: the forging is heated up with the furnace, heated to 700°C, held for 8 hours, cooled to 500°C in the furnace, and air-cooled to room temperature after being released from the furnace.

[0044] (2) Incomplete annealing: the forging is heated up with the furnace, heated to 1000 ° C, holding time for 2 hours, cooled to 500 ° C in the furnace, and air-cooled to room temperature after being released from the furnace.

[0045] (3) Secondary high-temperature tempering: the forging is heated up with the furnace, heated to 700°C, held for 8 hours, cooled to 500°C in the furnace, and air-cooled to room temperature after being released from the furnace.

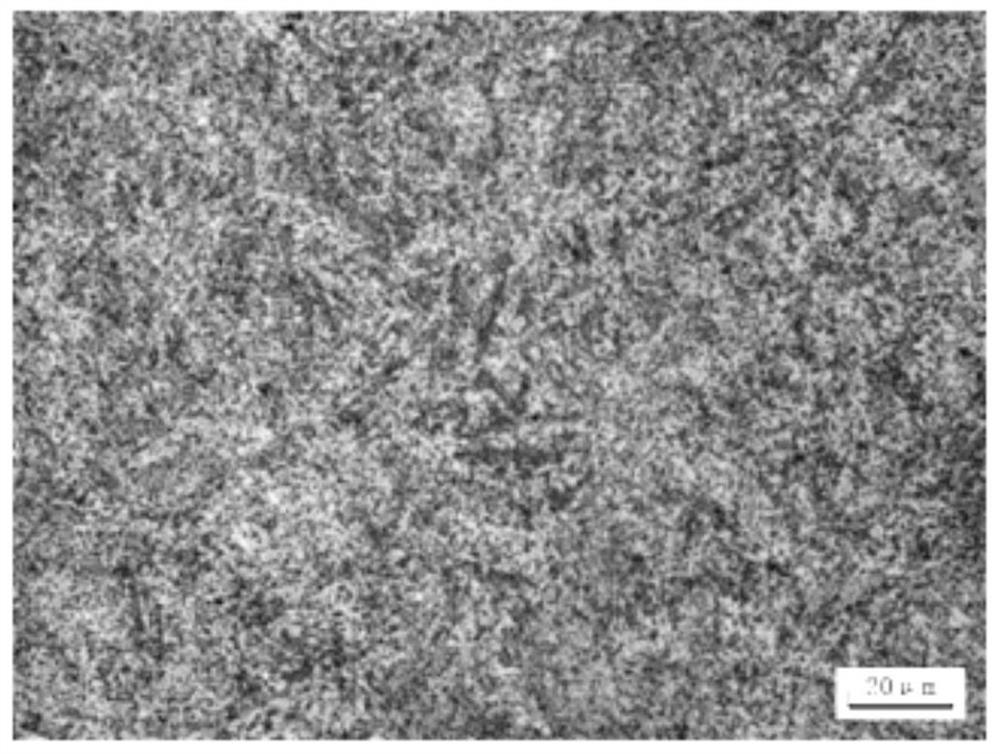

[0046] 3. Microstructure and hardness

[0047] Forging microstructure see figure 2 , is a granular carbide dispersed on the tempered sorbite...

Embodiment 3

[0049] 1. Processing object: super strong and high toughness carburized steel cylindrical gear forgings

[0050] 2. Preparatory heat treatment process

[0051] (1) Primary high-temperature tempering: the forging is put into the furnace when it reaches temperature, the heating temperature is 670°C, the holding time is 12h, and it is air-cooled to room temperature.

[0052] (2) Incomplete annealing: the forging is heated up with the furnace, heated to 980°C, held for 1.5h, and cooled to room temperature in air.

[0053] (3) Secondary high-temperature tempering: the forging is heated up with the furnace, heated to 670°C, held for 12 hours, and air-cooled to room temperature.

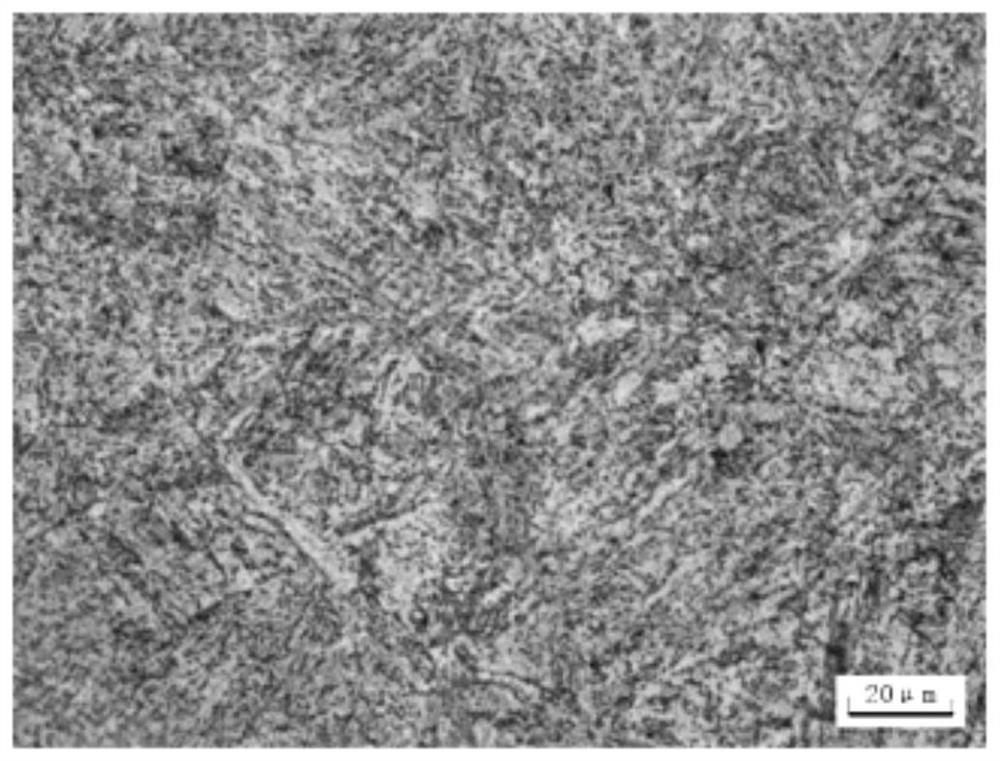

[0054] 3. Microstructure and hardness

[0055] Forging microstructure see image 3 , is a granular carbide dispersed on the tempered sorbite matrix, with a hardness of 32HRC.

[0056] Table 1

[0057]

[0058] Table 2

[0059]

[0060] After the above process, the rods or forgings in the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com