Gallium arsenide solar cell with gradient tunnel junction and manufacturing method of gallium arsenide solar cell

A technology for solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the current density of solar cells, reducing the crystal quality of top cells, and narrowing the production process window, so as to reduce light absorption capacity and improve tunneling. Penetration ability, the effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A gallium arsenide solar cell with a graded tunnel junction, from bottom to top is Ge substrate, bottom cell, buffer layer, first tunnel junction, DBR, middle cell, second tunnel junction, top cell and A capping layer; wherein, the first tunnel junction and the second tunnel junction have the same structure, and both adopt a graded tunnel junction structure.

[0048] The specific manufacturing method of the gallium arsenide solar cell is as follows:

[0049] S1. On a P-type Ge substrate, pass PH at high temperature 3 In the form of diffusion, the emitter region of the bottom cell is formed, and then the GaInP nucleation layer is grown, and the nucleation layer serves as the window layer of the bottom cell at the same time;

[0050] S2. Then grow In on the bottom cell 0.01 GaAs buffer layer, where In 0.01 GaAs buffer layer thickness is 0.1μm;

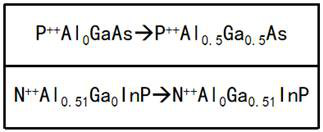

[0051] S3. Then grow a first tunnel junction on the buffer layer, the first tunnel junction is N ++ Al x1 Ga y1 InP / P ++...

Embodiment 2

[0058] A gallium arsenide solar cell with a graded tunnel junction, from bottom to top is Ge substrate, bottom cell, buffer layer, first tunnel junction, DBR, middle cell, second tunnel junction, top cell and A capping layer; wherein, the first tunnel junction and the second tunnel junction have the same structure, and both adopt a graded tunnel junction structure.

[0059] The specific manufacturing method of the gallium arsenide solar cell is as follows:

[0060] S1. On a P-type Ge substrate, pass PH at high temperature 3 In the form of diffusion, the emitter region of the bottom cell is formed, and then the GaInP nucleation layer is grown, and the nucleation layer serves as the window layer of the bottom cell at the same time;

[0061] S2. Then grow In on the bottom cell 0.01 GaAs buffer layer, where In 0.01 GaAs buffer layer thickness is 0.5μm;

[0062] S3. Then grow a first tunnel junction on the buffer layer, the first tunnel junction is N ++ Al x1 Ga y1 InP / P ++...

Embodiment 3

[0069] A gallium arsenide solar cell with a graded tunnel junction, from bottom to top is Ge substrate, bottom cell, buffer layer, first tunnel junction, DBR, middle cell, second tunnel junction, top cell and A capping layer; wherein, the first tunnel junction and the second tunnel junction have the same structure, and both adopt a graded tunnel junction structure.

[0070] The specific manufacturing method of the gallium arsenide solar cell is as follows:

[0071] S1. On a P-type Ge substrate, pass PH at high temperature 3 In the form of diffusion, the emitter region of the bottom cell is formed, and then the GaInP nucleation layer is grown, and the nucleation layer serves as the window layer of the bottom cell at the same time;

[0072] S2. Then grow In on the bottom cell 0.01 GaAs buffer layer, where In 0.01 GaAs buffer layer thickness is 0.8μm;

[0073] S3. Then grow a first tunnel junction on the buffer layer, the first tunnel junction is N ++ Al x1 Ga y1 InP / P ++...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com