Ti3C2Tx-coated g-C3N4 composite material as well as preparation method and application thereof

A composite material, g-c3n4 technology, applied in the field of Ti3C2Tx@g-C3N4 composite material and its preparation, can solve the problems of irreversible capacity loss, inability to protect lithium metal from continuous corrosion, uncontrollable growth of lithium dendrites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides the Ti described in the above-mentioned technical scheme 3 C 2 T x @g-C 3 N 4 The preparation method of composite material, comprises the following steps:

[0038] Ti 3 C 2 T x Nanosheets, carbon nitride precursors and water are mixed to obtain a mixed dispersion; the Ti 3 C 2 T x The mass ratio of nanosheets and carbon nitride precursors is 1:3-9;

[0039] Freezing and drying the mixed dispersion in sequence to obtain a solid composite;

[0040] Calcining the solid composite to obtain Ti 3 C 2 T x @g-C 3 N 4 composite material.

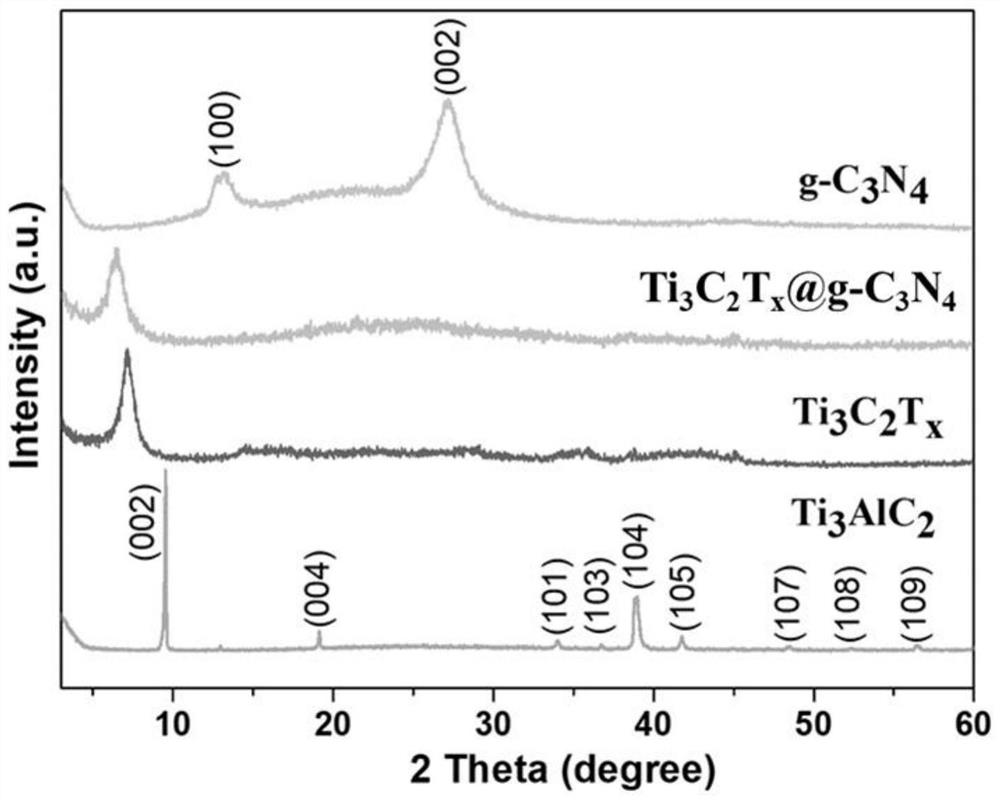

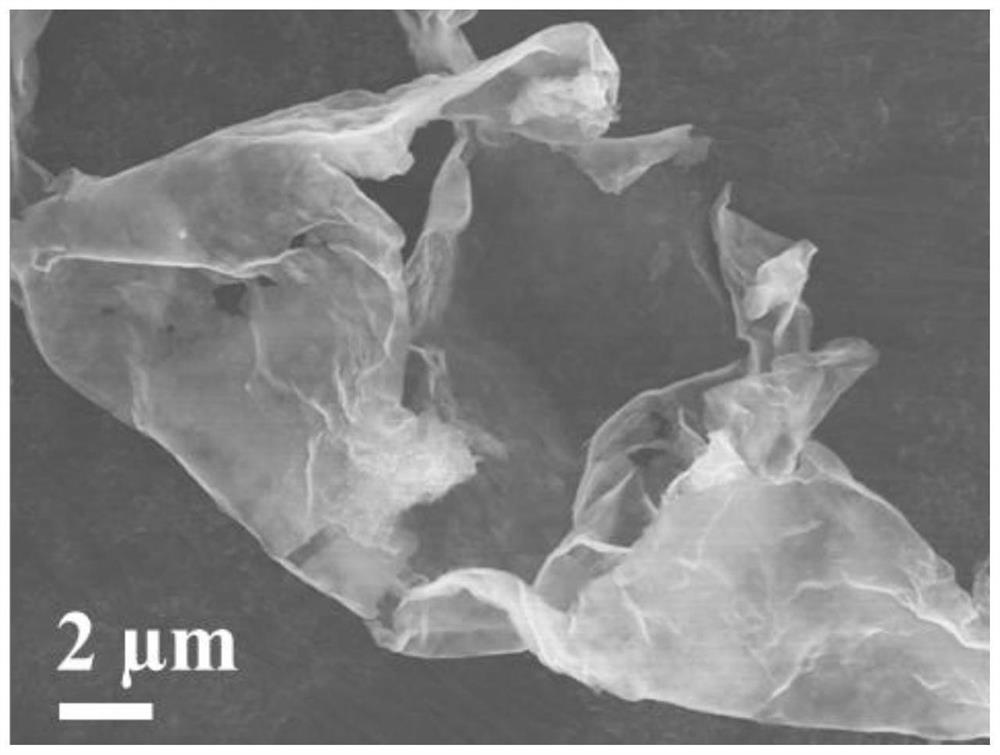

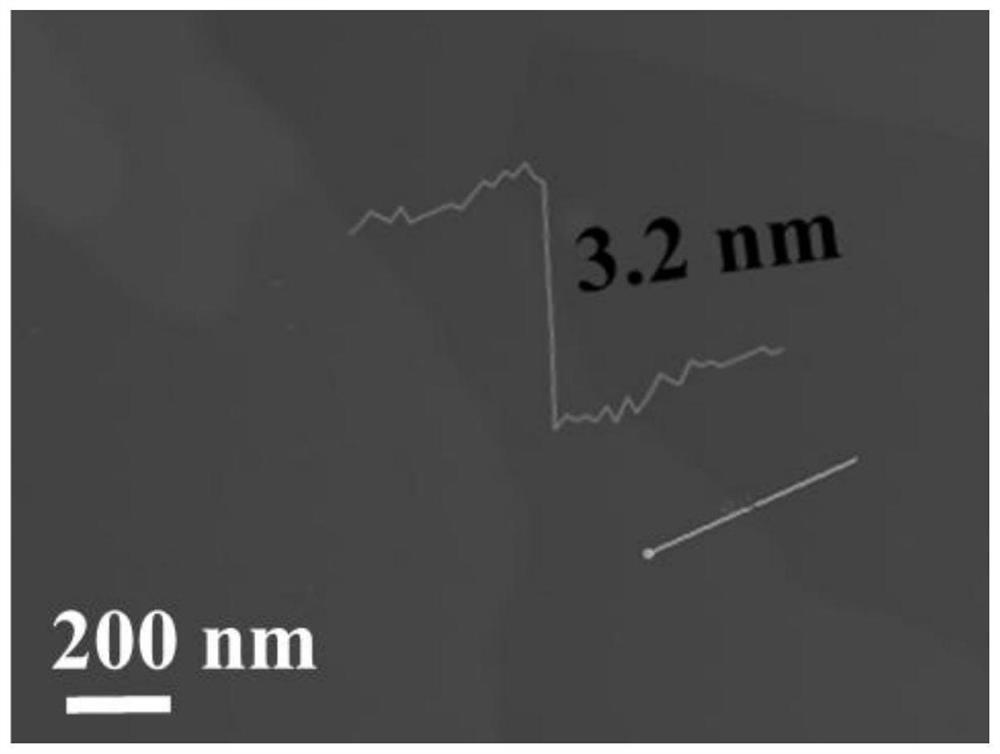

[0041] The invention prepares Ti by self-assembly and in-situ calcination reaction 3 C 2 T x @g-C 3 N 4 Composite materials, during the self-assembly process, carbon nitride precursors are deposited on Ti 3 C 2 T x Nanosheet surface, so that the carbon nitride precursor is uniformly distributed on the Ti 3 C 2 T x Nanosheet surface; during calcination, carbon nitride precursors con...

Embodiment 1

[0055] (1) Ti 3 C 2 T x Synthesis of Nanosheets.

[0056] Add 0.8g lithium fluoride to 10mL hydrochloric acid solution (concentration: 9mol / L), stir for 10min; then add 0.5gTi 3 AlC 2 Slowly added to the above solution, stirred for 24h; washed with deionized water until the pH value of the filtrate was 6; centrifuged at 3500rpm for 1h to obtain a stable suspension; put the suspension at a low temperature of -40°C Freeze for 12 hours, and then dry for 50 hours under a vacuum environment of 5Pa to obtain dry and fluffy black Ti 3 C 2 T x Nanosheets.

[0057] (2) Ti 3 C 2 T x - Synthesis of DCD complex.

[0058] 100mg of the Ti 3 C 2 T x The nanosheets were dispersed in 50 mL of deionized water, 500 mg of dicyandiamide (DCD) was added, and stirred for 3 hours to obtain a mixed dispersion; the mixed dispersion was frozen at a low temperature of -40°C for 12 hours, and then placed in a vacuum environment of 5 Pa Dry for 50h to get Ti 3 C 2 T x - DCD complex.

[0...

Embodiment 2

[0062] It is basically the same as Example 1, except that the amount of DCD is adjusted from "500mg" to "700mg".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com