Preparation method and application of CoN/Ti3C2 material with foamed nickel as substrate

A nickel foam and substrate technology, applied in the field of Ti3C2 composite materials, can solve the problems of platinum scarcity, high price, poor stability, etc., and achieve the effect of reducing charge transfer resistance, good morphology and structure, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

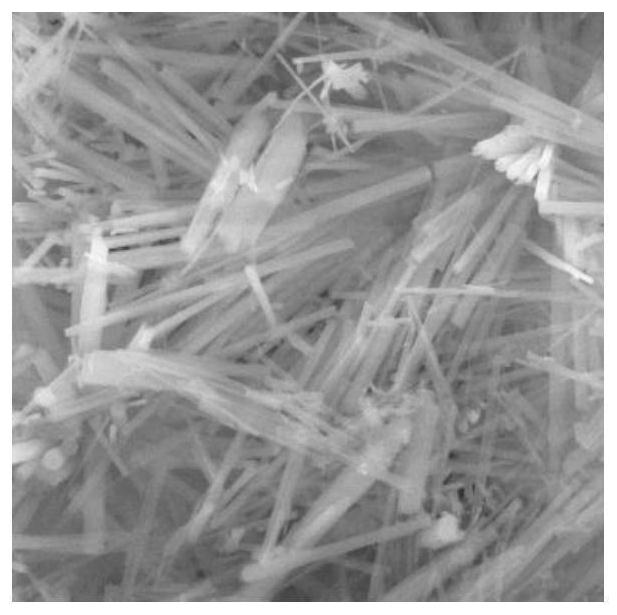

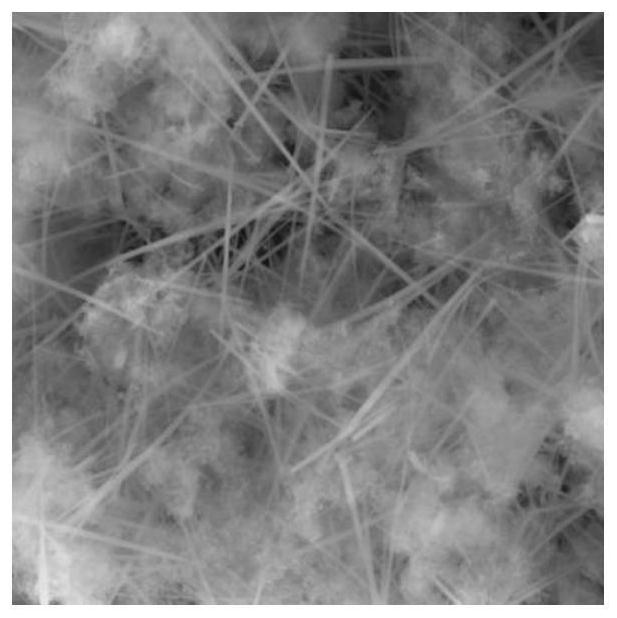

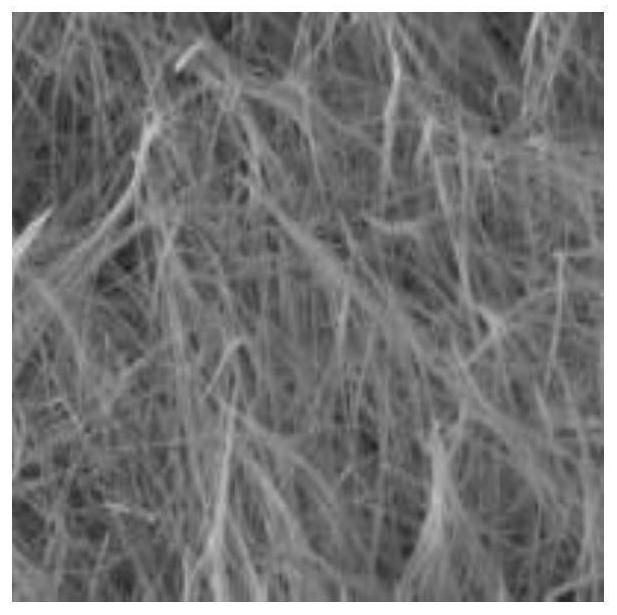

Image

Examples

Embodiment 1

[0035] 1. Pretreatment of nickel foam:

[0036] Cut the nickel foam into a square shape with a size of 1cm*1cm and wait for treatment; dilute the acetic acid in the laboratory to 3mol / L, so that the nickel foam is ultrasonically treated with acetic acid, absolute ethanol, and deionized water (all volumes are 20ml) for 10 minutes respectively To remove impurities on the surface of nickel foam.

[0037] 2. The method of physical mixing is used to prepare Ti-containing 3 C 2 The solution:

[0038] 3mmol Ti 3 C 2 (about 0.192 g) was added to 10 ml of deionized water and sonicated at 25° C. for 30 minutes until uniformly mixed.

[0039] 3. Preparation of CoN precursor

[0040] Mix 12ml of distilled water and 12ml of ethylene glycol evenly, then weigh 3mmol of urea (about 0.18g), 3mmol of cobalt nitrate hexahydrate (about 0.873g), and 3mmol of CTAB (about 1.093g) into the above-mentioned solution in sequence, and stirred at room temperature for 30 min under the action of a ma...

Embodiment 2

[0046] 1. Pretreatment of nickel foam:

[0047] Cut the nickel foam into a square shape with a size of 1cm*1cm and wait for treatment; dilute the acetic acid in the laboratory to 3mol / L, so that the nickel foam is ultrasonically treated with acetic acid, absolute ethanol, and deionized water (all volumes are 20ml) for 10 minutes respectively To remove impurities on the surface of nickel foam.

[0048] 2. The method of physical mixing is used to prepare Ti-containing 3 C 2 The solution:

[0049] 2mmol Ti 3 C 2 (about 0.128 g) was added into 10 ml of deionized water, and ultrasonically treated at 25° C. for 30 minutes until the mixed solution was ultrasonically oscillated until uniformly mixed.

[0050] 3. Preparation of CoN precursor

[0051] Mix 12ml of distilled water and 12ml of ethylene glycol evenly, then weigh 3mmol of urea (about 0.18g), 3mmol of cobalt nitrate hexahydrate (about 0.873g), and 3mmol of CTAB (about 1.093g) into the above-mentioned solution in sequenc...

Embodiment 3

[0057] 1. Pretreatment of nickel foam:

[0058] Cut the nickel foam into a square shape with a size of 1cm*1cm and wait for treatment; dilute the acetic acid in the laboratory to 3mol / L, so that the nickel foam is ultrasonically treated with acetic acid, absolute ethanol, and deionized water (all volumes are 20ml) for 10 minutes respectively To remove impurities on the surface of nickel foam.

[0059] 2. The method of physical mixing is used to prepare Ti-containing 3 C 2 The solution:

[0060] 2mmol Ti 3 C 2 (about 0.128 g) was added into 10 ml of deionized water, and ultrasonically treated at 25° C. for 30 minutes until the mixed solution was ultrasonically oscillated until uniformly mixed.

[0061] 3. Preparation of CoN precursor

[0062] Mix 12ml of distilled water and 12ml of ethylene glycol evenly, then weigh 3mmol of urea (about 0.18g), 3mmol of cobalt nitrate hexahydrate (about 0.873g), and 2mmol of CTAB (about 0.7289g) and add them to the above-mentioned solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com