Modified catalyst, membrane electrode and preparation method thereof, and fuel cell

A catalyst and membrane electrode technology, applied in the field of modified catalysts, membrane electrodes and their preparation methods and fuel cells, can solve problems such as poor durability of catalysts or catalyst layers, reduce the number of defects, reduce oxygen content, and achieve large-scale The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Add 50 mg of commercial Pt / C catalyst (JM (Johnson Matthey, Johnson) 60% Pt / C) to the polytetrafluoroethylene reactor liner, ultrasonically disperse in 50 mL deionized water, and the ultrasonic frequency is 50 kHz, Ultrasound continued for 10 minutes; 6.4 mg of potassium borohydride was added to the above dispersion and stirred at a stirring rate of 500 rpm for 30 minutes; Aged for 6 hours, cooled to room temperature, then collected by centrifugation at 10,000 rpm, and dried at 80°C for 6 hours to obtain a highly stable platinum-carbon catalyst, which was designated as Pt / C-1.

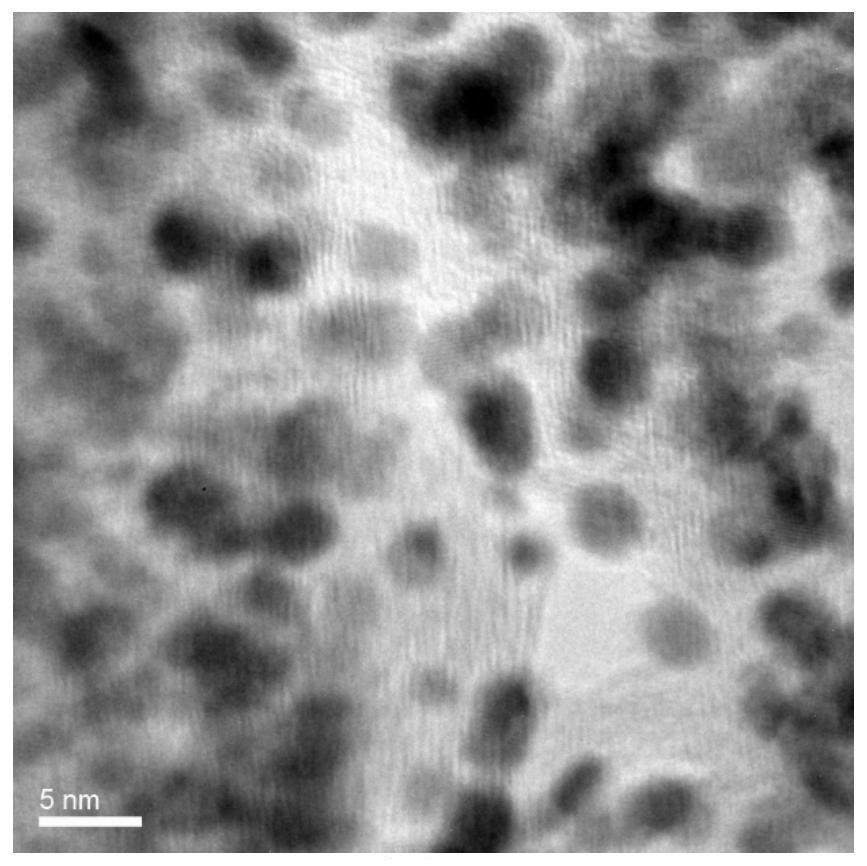

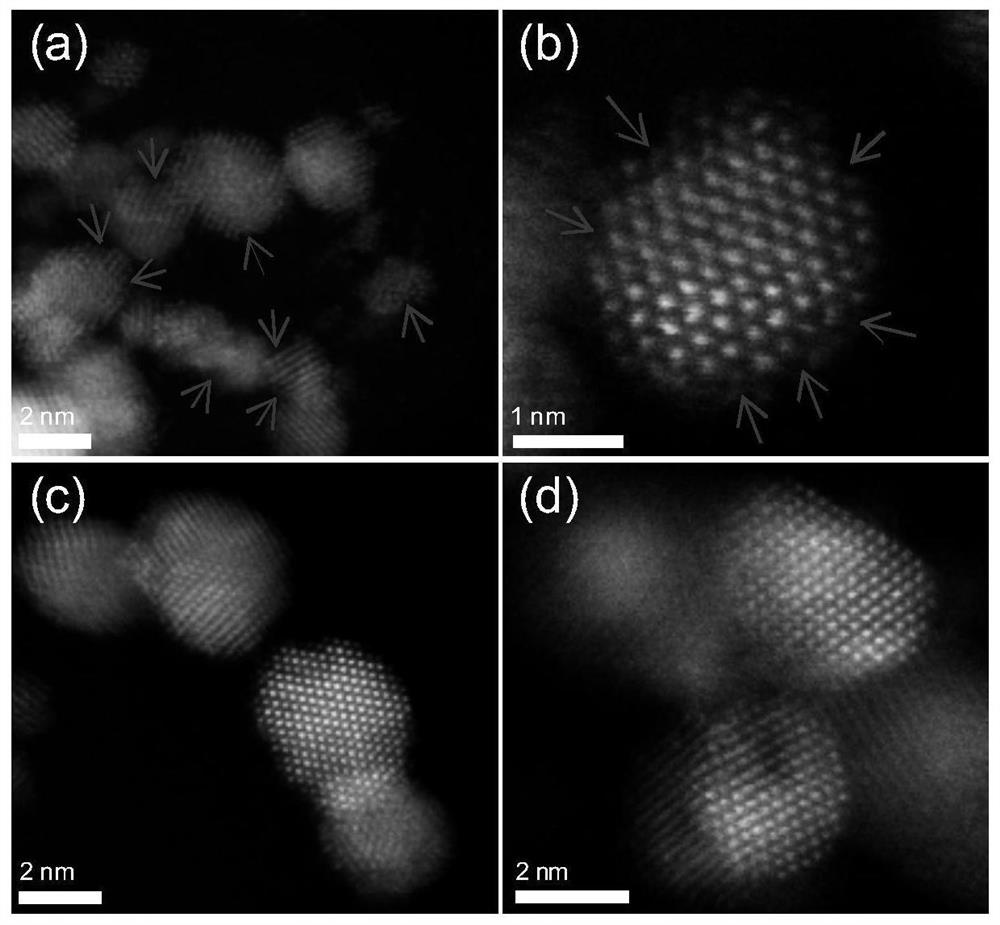

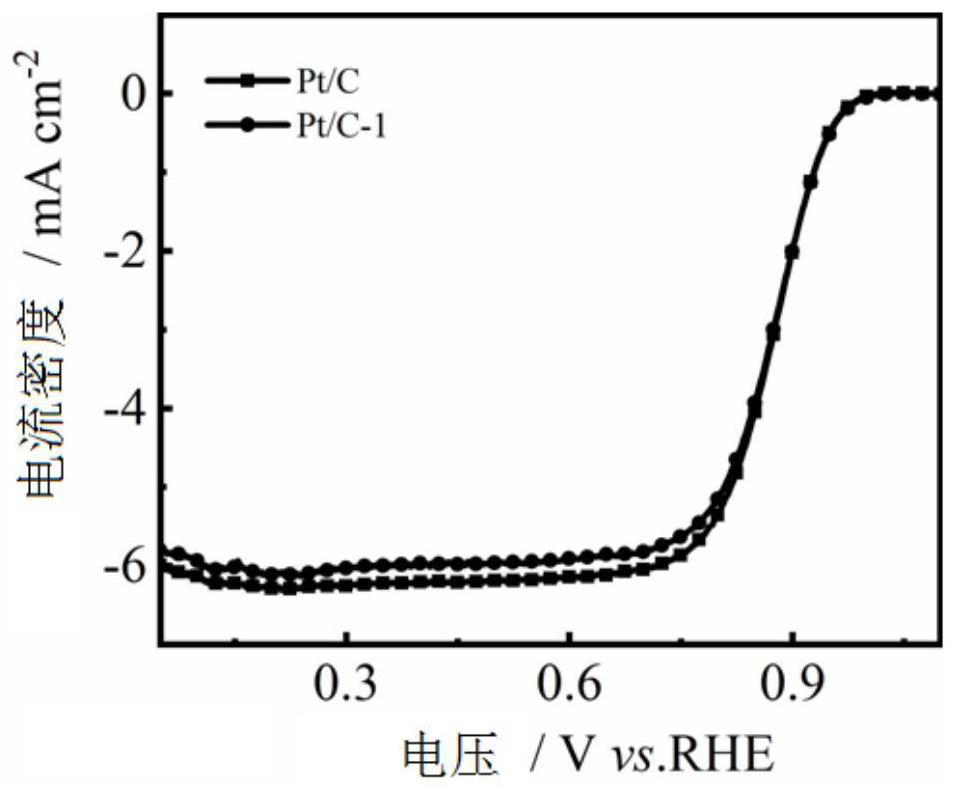

[0059] After X-ray photoelectron spectroscopy (XPS) analysis, the oxygen content on the carbon carrier surface of Pt / C-1 is 5.71 at.%; the average particle diameter of platinum particles is 3.40nm. Pt / C-1 platinum metal particles have few defects and regular appearance, specifically as figure 1 As shown, compared with commercial Pt / C, the defects of Pt / C-1 in this example are significantly redu...

Embodiment 2

[0062] The modification method of the catalyst in Example 2 is basically the same as in Example 1, except that the mass of potassium borohydride is changed to 3.2 mg to obtain a highly stable platinum carbon catalyst, which is denoted as Pt / C-2.

[0063] After X-ray photoelectron spectroscopy (XPS) analysis, the oxygen content on the surface of the Pt / C-2 carbon carrier is 6.90 at.%, and the average particle diameter of the platinum particles is 3.30nm.

Embodiment 3

[0065] Add 50 mg of commercial PtCo / C catalyst to the polytetrafluoroethylene reactor liner, ultrasonically disperse it in 50 ml of methanol, the ultrasonic frequency is 100KHz, and the ultrasonic wave lasts for 10 minutes; add 15 mg of citric acid to the above dispersion, Stirring, the stirring rate is 500rpm, and the stirring time is 30min; then the obtained reaction kettle with the mixed solution is placed in an oven at a reaction temperature of 160°C for 10 hours, then cooled to room temperature, and then collected by centrifugation at 5000rpm, 100 ℃ drying for 6 hours to obtain a highly stable PtCo / C catalyst, denoted as PtCo / C-3.

[0066] Then take 30mg of the PtCo / C-3 obtained above, and ultrasonically disperse it into 30ml of methanol solution with perfluorosulfonic acid resin (the mass ratio of PtCo / C-5 catalyst to perfluorosulfonic acid resin is 6:40) to configure For the slurry, the ultrasonic frequency is 100kHz, the ultrasonic time is 30min, and the ultrasonic tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com