Juicy peach freezing device and freezing method

A technology for freezing devices and juicy peaches, which can be used in household refrigeration devices, measuring devices, and preservation of fruits/vegetables through freezing/refrigerating, etc. It can solve problems such as poor product quality, juice loss, and environmental protection pressure, and improve product quality and safety. , Prevent fruit deterioration and prolong shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 To attach Figure 5 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

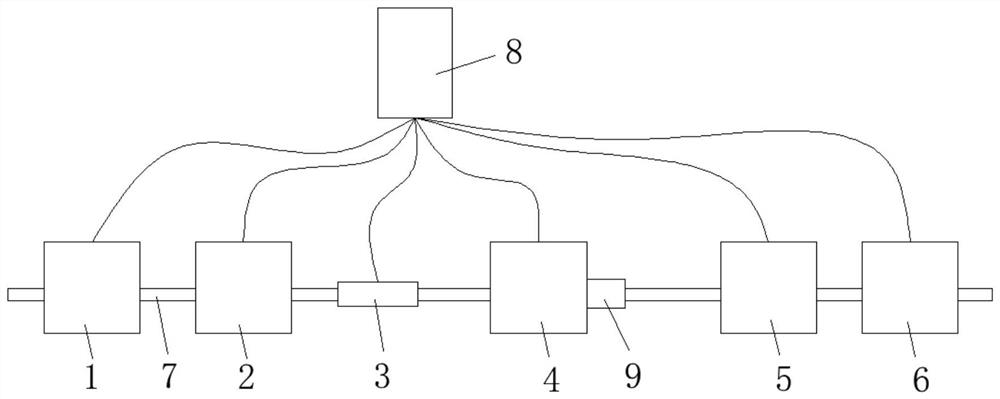

[0046] figure 1 It is a schematic structural view of a peach freezing device of the present invention. Such as figure 1 As shown, the peach freezing device provided by the present embodiment includes: a cleaning and disinfection chamber 1, a radio frequency irradiation chamber 2, a radio frequency suppressor 3, a constant temperature chamber 4, a cooling chamber 5, a quick freezing chamber 6, a conveyor belt 7 and a control cabinet 8, Among them, the cleaning and disinfection chamber 1, the radio frequency irradiation chamber 2, the radio frequency suppressor 3, the constant temperature cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com