Application of PEG (Polyethylene Glycol) compound in preparation of embolism agent

The technology of a compound and an embolic agent is applied in the application field of PEG compound as the preparation of an embolic agent, which can solve the problems such as complicated operation of the embolic agent, and achieve the effects of convenient use and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

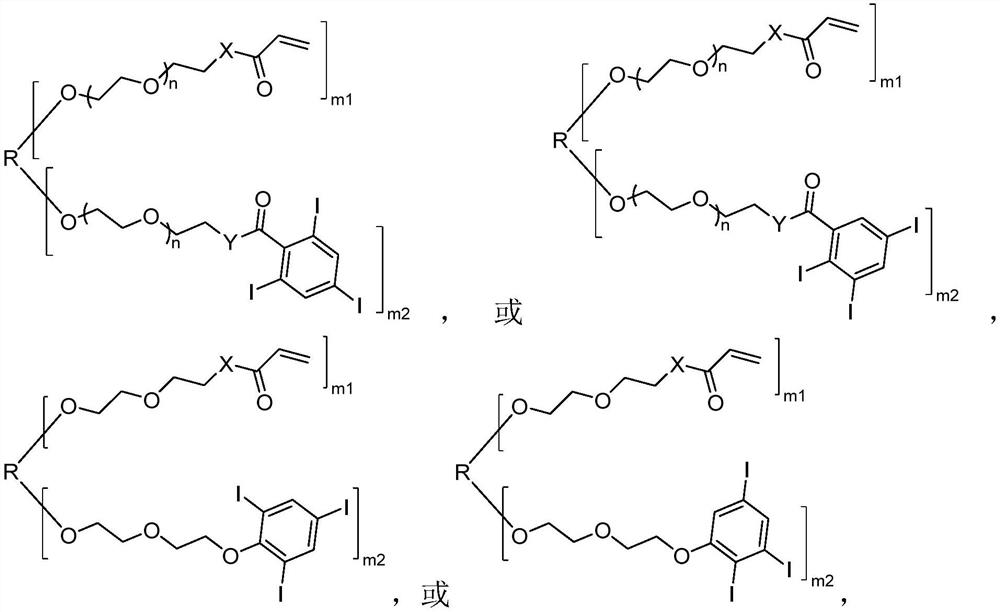

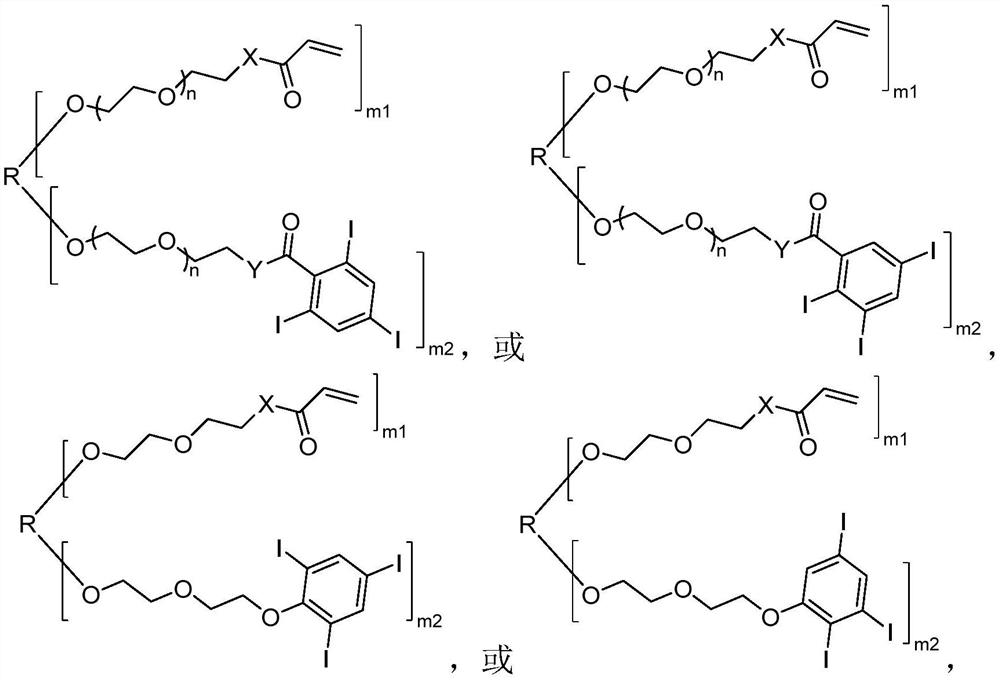

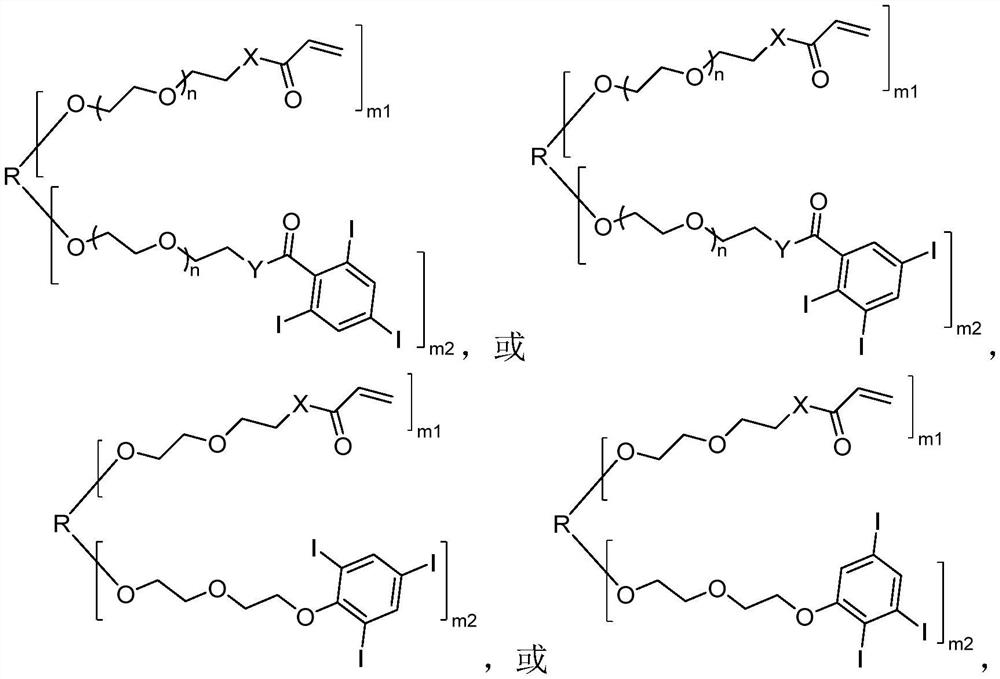

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 10.0 g of 3-arm-2,3,5-triiodobenzamide acrylamide polyethylene glycol, 0.2 g of N,N-methylene acrylamide, 0.5 g of ethyl methacrylate, and 0.12 g of ammonium persulfate In 30ml of purified water, sonicate for 10min, filter with a 0.45um water filter membrane, and obtain the filtrate for later use.

[0027] Add 8.0 g of liquid paraffin to 2.0 liters of petroleum ether, ultrasonically degas for 30 minutes, stir and cool down to 0-10°C, and set aside.

[0028] After cooling the oil phase to 0-10°C, add 0.3g of tetramethylethylenediamine and stir for 3min at a speed of 300r / min, slowly drop half of the water phase into it, stir for 10-30min, then drop into the other half, and stir for 10- 30min, raise the temperature to 30°C, adjust the speed to 600r / min, stir for 1h, raise the temperature to 60°C, continue to stir for 5h, add 200ml of purified water, stir for 20min, filter to obtain microspheres, and swell the microspheres with normal saline for injection After 3...

Embodiment 2

[0030] Dissolve 10.0 g of 8-arm-2,3,5-triiodobenzamide acrylamide polyethylene glycol, 0.2 g of N,N-methylene acrylamide, 0.5 g of ethyl methacrylate, and 0.12 g of ammonium persulfate In 30ml of purified water, sonicate for 10min, filter with a 0.45um water filter membrane, and obtain the filtrate for later use.

[0031] Add 8.0 g of liquid paraffin to 2.0 liters of petroleum ether, ultrasonically degas for 30 minutes, stir and cool down to 0-10°C, and set aside.

[0032] After cooling the oil phase to 0-10°C, add 0.3g of tetramethylethylenediamine and mix for 3min at a speed of 300r / min, slowly drop half of the water phase into it, stir for 10-30min, then drop into the remaining half, and stir 10-30min, heat up to 30°C, adjust the speed to 600r / min, stir for 1h, heat up to 60°C, continue stirring for 5h, add 200ml of purified water, stir for 20min, filter to get microspheres, use the microspheres for injection Saline was swollen for 30 minutes, injected into the microcathet...

Embodiment 3

[0034] Dissolve 10.0 g of 6-arm-2,3,5-triiodophenol acrylamide polyethylene glycol, 0.2 g of N,N-methylene acrylamide, 0.5 g of ethyl methacrylate, and 0.12 g of ammonium persulfate in 30 ml Purified water was sonicated for 10 min, filtered with a 0.45um water filter membrane, and the filtrate was obtained for future use.

[0035] Add 8.0 g of liquid paraffin to 2.0 liters of petroleum ether, ultrasonically degas for 30 minutes, stir and cool down to 0-10°C, and set aside.

[0036] After cooling the oil phase to 0-10°C, add 0.3g of tetramethylethylenediamine and mix for 3min at a speed of 300r / min, slowly drop half of the water phase into it, stir for 10-30min, then drop into the remaining half, and stir 10-30min, heat up to 30°C, adjust the speed to 600r / min, stir for 1h, heat up to 60°C, continue stirring for 5h, add 200ml of purified water, stir for 20min, filter to get microspheres, use the microspheres for injection Saline was swollen for 30 minutes, injected into the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com