Solid solution forging process for aluminum alloy part

A technology for aluminum alloy parts and aluminum alloys, which is applied in the field of forging technology, can solve the problems of reducing the mechanical properties and dimensional stability of the parts, the aluminum alloy parts are prone to coarse grains, and increasing the manufacturing cost, so as to save the manufacturing process and the quality of the billet. The effect of increasing and reducing the proportion of coarse crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

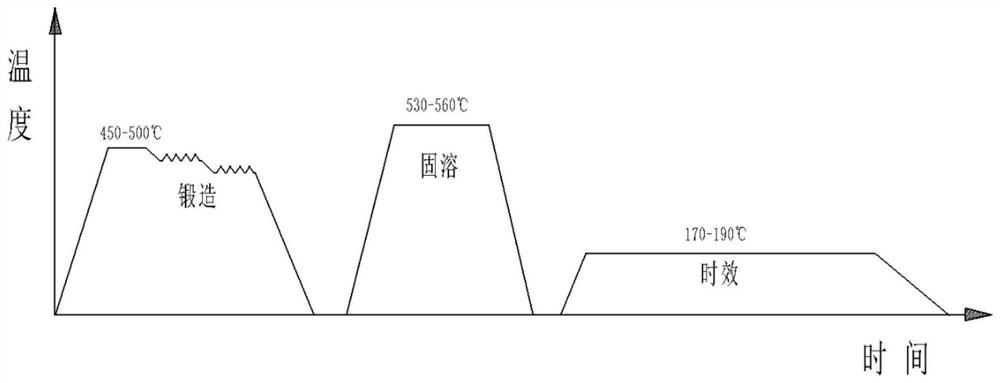

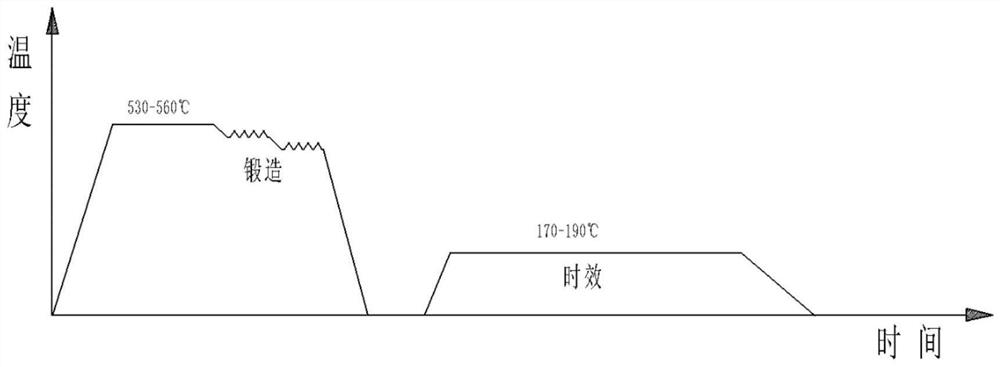

[0047] Embodiment 1, figure 1 It shows a schematic diagram of a traditional T process of an aluminum alloy material part in the prior art, figure 2 It shows a schematic diagram of the solid solution forging process of an aluminum alloy material part of the present invention, according to the attached figure 2 , the invention provides a solid solution forging process for aluminum alloy parts, the manufacturing process is as follows:

[0048] (1) Cutting

[0049] Obtain aluminum alloy part blanks;

[0050] (2) Solid solution heating

[0051] Using an aluminum alloy solid solution furnace to heat the above-mentioned billet, and obtain a billet containing a solid solution structure after heating;

[0052] (3) Solid solution forging

[0053] The blank obtained in the step (2) is quickly put into a mechanical press and adopts a forging die to carry out solid solution forging forming, and after forging and forming, put it into water and take it out after direct rapid cooling; ...

Embodiment 2

[0075] Its chemical composition and manufacturing process are the same as in Example 1. Aluminum alloy blanks are forged into wheel parts, and the aluminum alloy wheel parts prepared by the present invention are processed according to "GB / T 16865-2013 Deformed Aluminum, Magnesium and Their Alloys" Tensile test specimens and methods" standard to test its performance, and the comparison results with the T process are shown in Table 3. The largest cross-section of parts prepared by solution forging is in accordance with the requirements of the standard "GB / T 3246.1-2012 Microstructure Inspection Method for Deformed Aluminum and Aluminum Alloy Products Part 1: Microstructure Inspection Method". The macroscopic surface after corrosion is as attached Figure 6 As shown, the macroscopic surface of the largest cross-section of the aluminum alloy valve body parts prepared by the T process after corrosion is shown in the attached Figure 5 shown. attached Figure 6 And attached Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com