UHPC/foamed aluminum anti-explosion composite structure and preparation method thereof

A technology of composite structure and aluminum foam, which is applied in the direction of chemical instruments and methods, protective equipment, and other household appliances, and can solve problems such as heavy weight, poor energy absorption effect, and insufficient toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

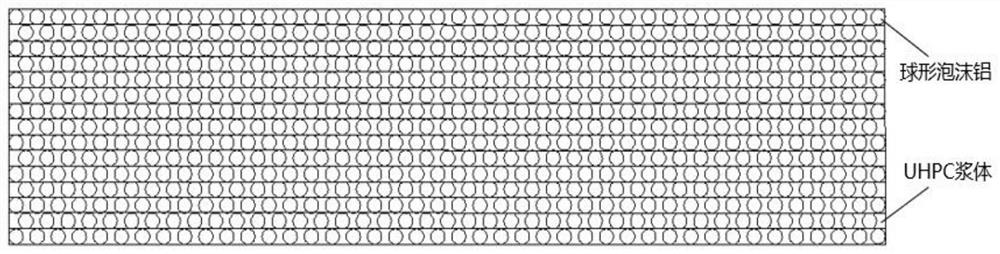

[0027] The UHPC / foam aluminum anti-explosion composite structure of the present invention will be described in more detail below in conjunction with the accompanying drawings and examples, but this should be used as a limit to the protection scope of the present application.

[0028] The core innovation of this application lies in the combination of the shock wave propagation theory, that is, the shock wave will be reflected on the surface of the lightweight low-impedance material during the propagation process, and for the irregular arrangement (the irregular arrangement refers to the The arrangement of the gradient distribution) will make the shock wave propagation process more complicated. A UHPC / foam aluminum anti-explosion composite panel structure is designed based on the concept. In addition, an interface adhesive is added between the layers to enhance the interface bonding performance of the panel, thereby improving the integrity of the panel structure.

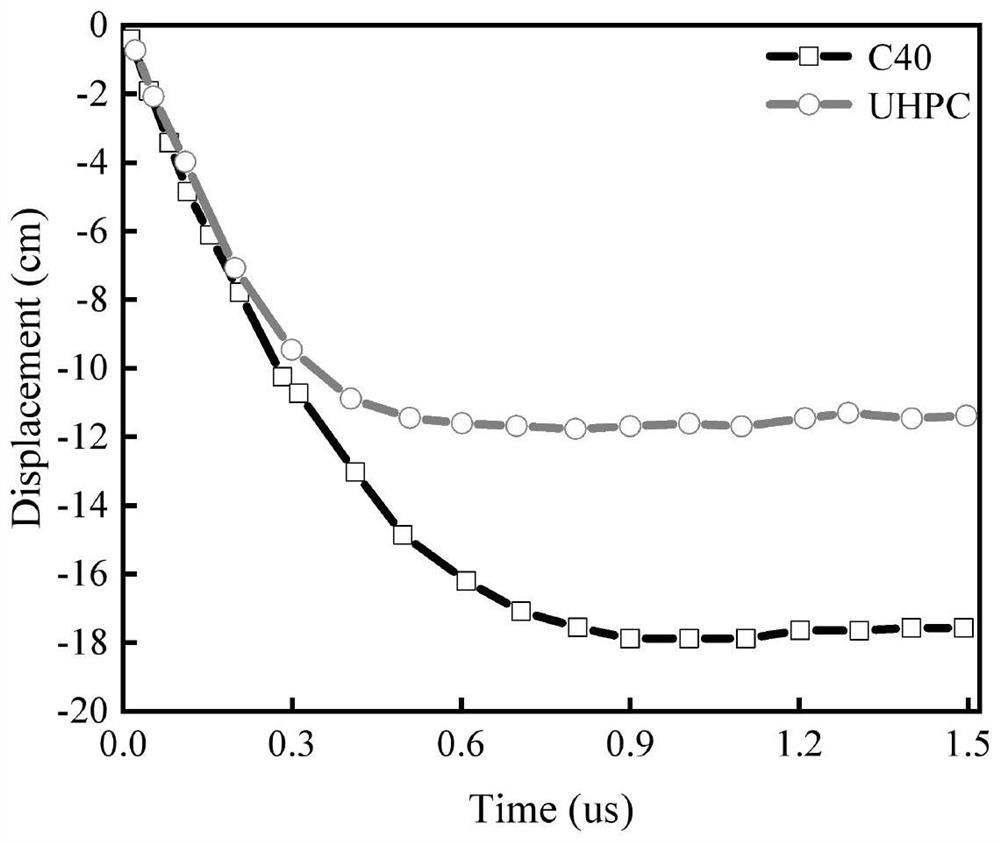

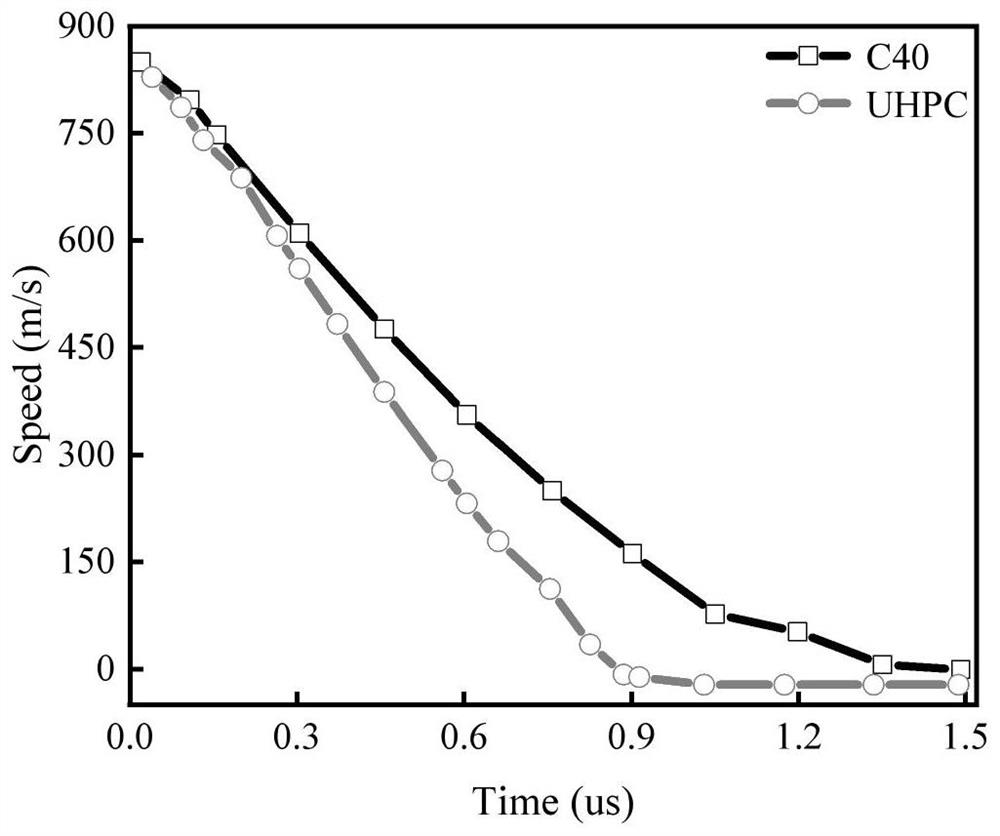

[0029] When m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com