Method for rapidly preparing high-conductivity graphene electromagnetic shielding film

A technology of electromagnetic shielding film and graphene film, which is applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of large energy consumption, low processing efficiency, and long preparation process of high-temperature graphitization, and achieve reduction Consumption and processing time, excellent electrical conductivity, widening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) The graphite oxide filter cake with an average size of 1000 μm is configured into an aqueous graphite oxide solution with a concentration of 20 mg / mL. Add ammonia water to the prepared solution to adjust the pH to 8, divide it in a high-speed shear disperser for 2 hours at a linear speed of 20m / s, and then use a vacuum mixer to assisted by a vacuum of -0.1MPa at a linear speed of 1m / s Stir slowly for 30 minutes to completely remove the bubbles to obtain a graphene oxide dispersion slurry;

[0036] 2) Apply the graphene oxide slurry evenly on the PET substrate to form a 2mm embryo film of graphene oxide film by doctor blade coating method, dry at 40°C for 8 hours to remove moisture, and peel off the substrate to obtain graphite oxide with a film thickness of 20 μm vinyl film;

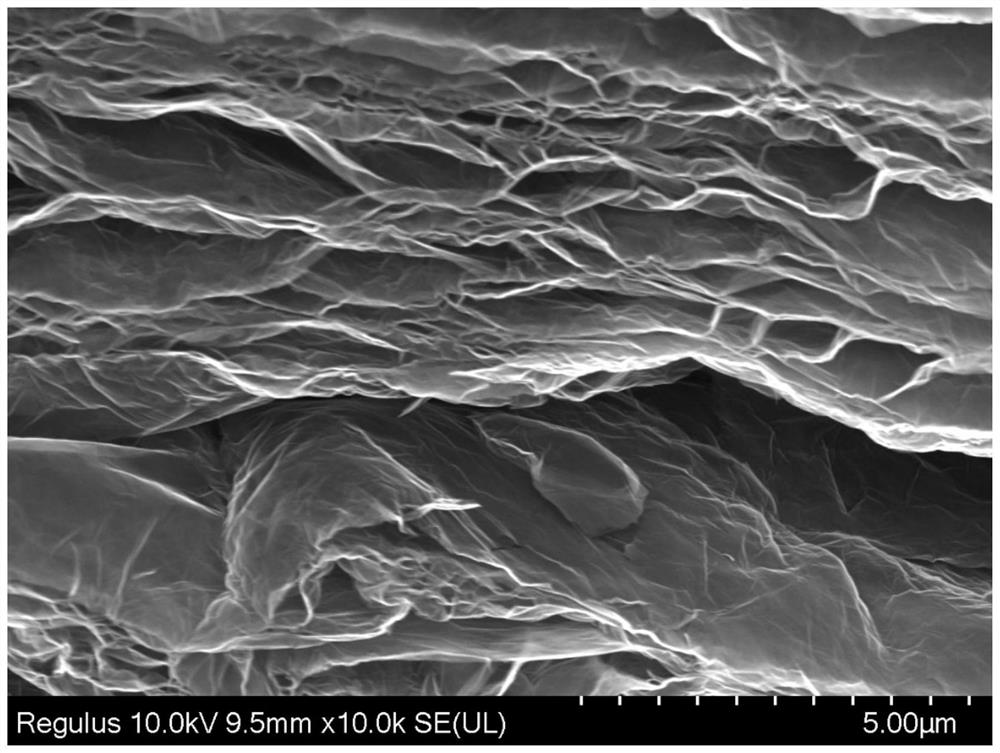

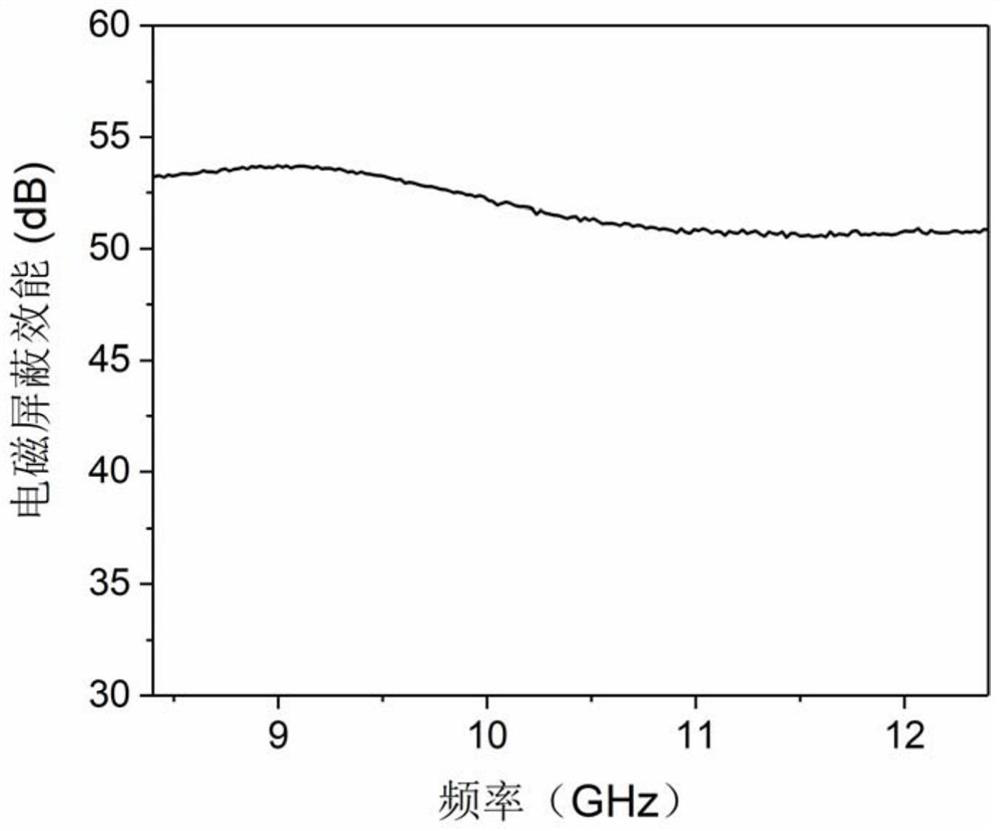

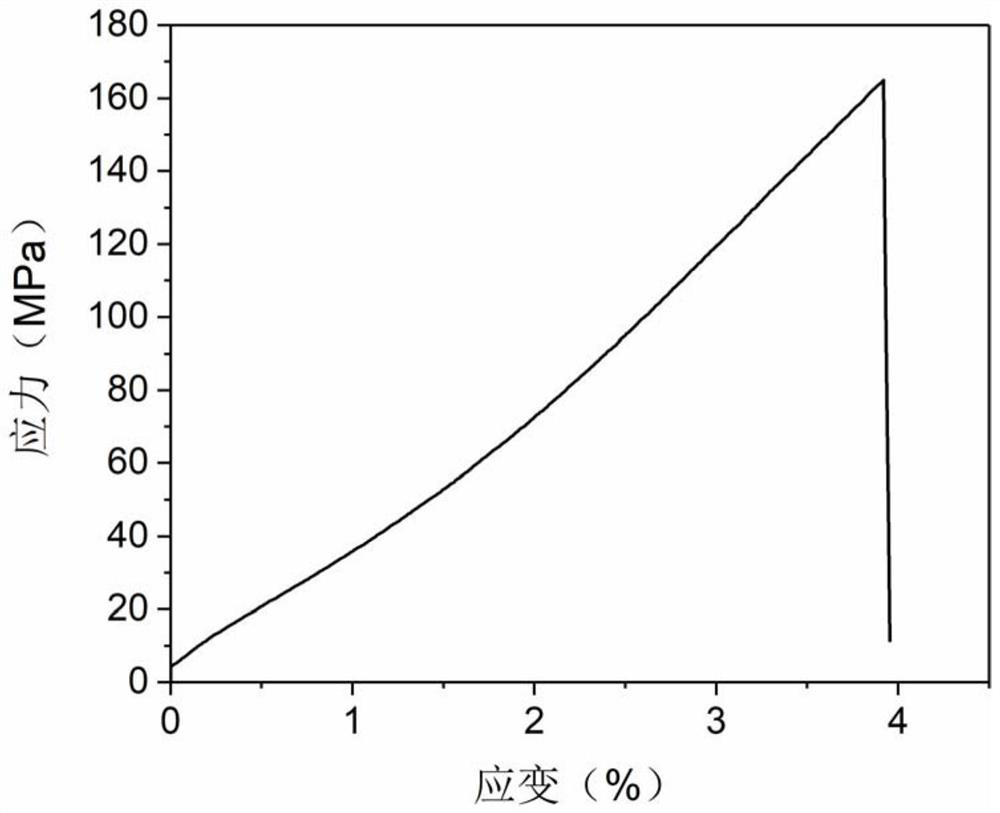

[0037] 3) In an air environment, use an infrared lamp with a surface temperature of 400°C to irradiate the graphene oxide film in step 2) for 20 seconds, then under the protection of an argon ...

Embodiment 2

[0043] 1) The graphite oxide filter cake with an average size of 500 μm is configured into an aqueous graphite oxide solution with a concentration of 30 mg / mL. Add ammonia water to the prepared solution to adjust the pH to 8, divide it in a high-speed shear disperser for 2 hours at a linear speed of 20m / s, and then use a vacuum mixer to assisted by a vacuum of -0.1MPa at a linear speed of 1m / s Stir slowly for 30 minutes to completely remove the bubbles to obtain a graphene oxide dispersion slurry;

[0044] 2) Apply the graphene oxide slurry evenly on the PET substrate to form a 3 mm embryonic film of graphene oxide film by the doctor blade coating method, dry at 40°C for 8 hours to remove moisture, and peel off the substrate to obtain graphite oxide with a film thickness of 45 μm vinyl film;

[0045] 3) In an air environment, use an infrared lamp with a surface temperature of 400°C to irradiate the graphene oxide film in step 2) for 20 seconds, then under the protection of an...

Embodiment 3

[0048] 1) The graphite oxide filter cake with an average size of 500 μm is configured into an aqueous graphite oxide solution with a concentration of 40 mg / mL. Add ammonia water to the prepared solution to adjust the pH to 8, divide it in a high-speed shear disperser at a line speed of 10m / s for 2h, and then use a vacuum mixer to assisted by a vacuum of -0.1MPa at a line speed of 1m / s Stir slowly for 30 minutes to completely remove the bubbles to obtain a graphene oxide dispersion slurry;

[0049] 2) Apply the graphene oxide slurry evenly on the PET substrate to form a 1 mm embryo film of graphene oxide film by doctor blade coating method, dry at 40°C for 8 hours to remove moisture, and peel off the substrate to obtain graphite oxide with a film thickness of 20 μm vinyl film;

[0050] 3) In an air environment, use an infrared lamp with a surface temperature of 400°C to irradiate the graphene oxide film in step 2) for 20 seconds, then under the protection of an argon atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com