Chromatographic separation method for glycerol glucoside

A technology for separating glycerin from glucoside, which is applied in the field of chromatographic separation, and can solve problems such as difficulty in achieving the separation effect of glycerin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

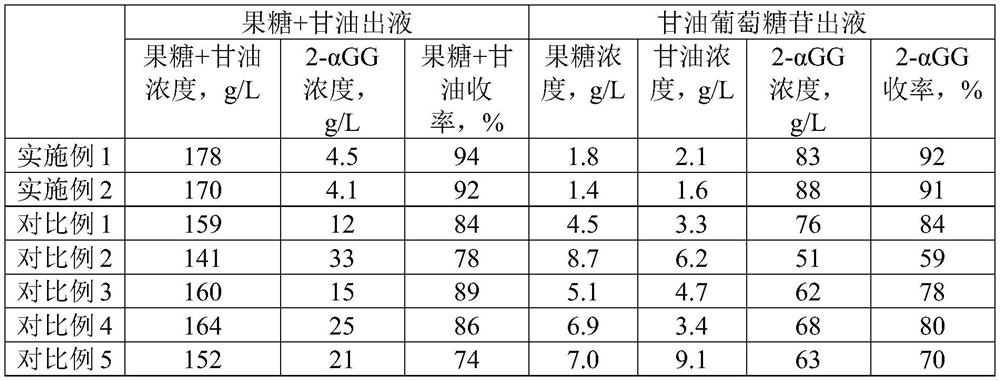

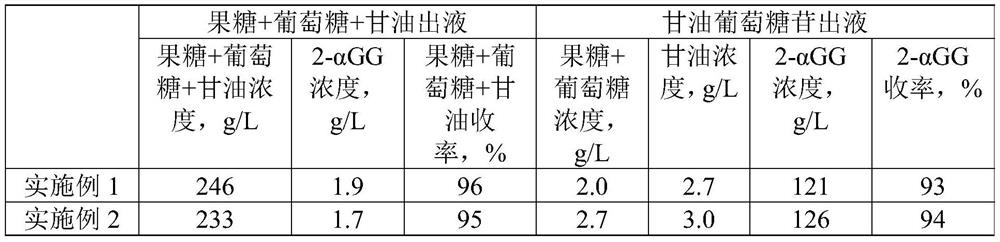

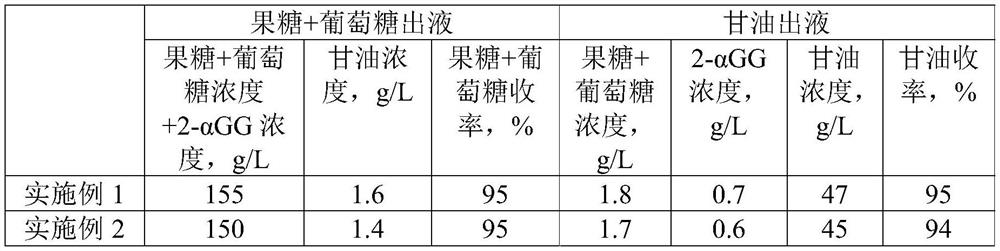

Examples

Embodiment 1

[0037] Through the following steps, the silicic acid modified calcium strontium type strongly acidic cation exchange resin of the present embodiment is prepared:

[0038] (1) 500ml of hydrogen-type strongly acidic cation exchange resin soaked in water (model 001x7, sieve the part with an outer diameter of microspheres of 0.2-0.4mm), put it in a 2000ml plastic cup, add 0.42mol / L calcium acetate aqueous solution at room temperature 1000ml for ion exchange, after continuous stirring for 2 hours, it is detected that the calcium concentration in the aqueous solution is lower than 0.002mol / L, drained, washed with 3000ml of water for 4 times, after washing, add water to a total volume of 650ml, pour into a glass bottle, cover and seal, and place at 75°C Place the homogenization treatment in the oven for 120 hours, turn it into hydrogen-calcium type strongly acidic cation exchange resin, and detect the calcium exchange degree of cations in the resin to be 83.1%; Acid group;

[0039] ...

Embodiment 2

[0044] Operate basically according to the steps (1)-(4) of Example 1 to prepare the calcium strontium type strong acidic cation exchange resin modified by silicic acid of this embodiment, the main difference is that the hydrogen type strong acidic cation exchange resin used in step (1) The resin model is 001x3, and the part of the microsphere outer diameter of 0.2-0.4mm is sieved, the concentration of calcium acetate aqueous solution is 0.35mol / L, and the calcium exchange degree of cations in the resin is detected to be 88.5%; step (2) prepares silicic acid-modified hydrogen Calcium type strongly acidic cation exchange resin contains about 0.35wt% of silicon dioxide in terms of dry resin and silicon dioxide; step (4) makes the calcium strontium type strongly acidic cation exchange resin modified by silicic acid, and detects the content of cations in the resin The exchange degree of strontium is 9.0%, and the exchange degree of calcium strontium is 100%.

Embodiment 3

[0056] Using 5 sets of chromatographic separation experimental devices with the same configuration, the separation experiments of glycerol and glucoside were carried out respectively. Each set of configuration chromatographic separation experimental device includes a self-made jacketed glass column and supporting control equipment; the inner diameter of the glass column is 22mm, and the height is 1500mm. Resin 400ml; Glycerol glucoside solution and mobile phase flow in and out, control the flow rate of the liquid, and the column temperature is controlled within 2°C of the required temperature by circulating hot water through the jacket, and the glycerol glucoside solution and mobile phase enter The temperature of the material is the same as the temperature of the column; the miniature photoelectric probe of the detector is inserted into the outlet pipe of the separation column to conduct continuous and real-time preliminary detection of the components of the outlet liquid. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com