Polymer electrolyte with semi-interpenetrating network structure and preparation method thereof

A network structure, polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as unfavorable comprehensive performance of polymer electrolytes, complex copolymerization reaction process, and impact on polymer electrolyte performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

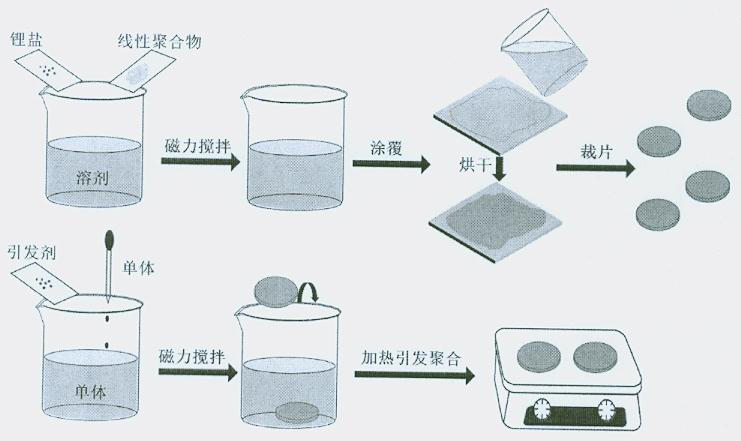

Method used

Image

Examples

Embodiment 1

[0033] (1) The mass ratio of 1: 5 is mixed with PVDF-HFP in 14 ml N, N-dimethylformamide solvent, and the temperature is controlled at 60 ° C, magnetic force for 12 h, and obtains a uniform and stable solution.

[0034] (2) Preparation of linear polymer electrolyte skeleton by solution casting method. The above solution was coated on a clean polytetrafluoroethylene groove or glass sheet to give the solution naturally. The polytetrafluoroethylene groove or glass plate was transferred to a vacuum oven in a vacuum oven in a vacuum oven. After film formation, a diameter of 19 mm was spared, and the film had a film of about 80 μm.

[0035] (3) The mass ratio of acrylonitrile and methacryl glyceride is sufficiently mixed, and the initiator AIBN of the monomer mass of 3% continues to be stirred and mixed into the precursor solution.

[0036] (4) The PVDF-HFP polymer wafer is fully immersed in the precursor solution, so that the precursor solution is sufficiently infiltrated into the surf...

Embodiment 2

[0038] (1) Mix the Litfsi of the molar ratio Li: EO = 1: 16 in 20 ml of acetonitrile solvent, and the temperature was controlled at 50 ° C, and the magnetic force was stirred for 12 h, and a uniform and stable solution was obtained.

[0039] (2) Preparation of linear polymer electrolyte skeleton by solution casting method. The above solution was coated on a clean polytetrafluoroethylene groove or glass sheet to give the solution naturally. The polytetrafluoroethylene groove or glass plate was transferred to a vacuum oven in a vacuum oven in a vacuum oven. After film formation, a diameter of 19 mm was spared, and the film had a thickness of about 140 μm.

[0040] (3) The mass ratio of acrylate and a vinyl carbonate of 3: 7 is thoroughly mixed, and a monomer mass 2% photoinitiator is subjected to a precursor solution.

[0041](4) The PEO polymer wafer is fully immersed in the precursor solution, so that the precursor solution is sufficiently infiltrated into the surface and inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com