Rubber material for manufacturing dumbbell and manufacturing process thereof

A rubber material and manufacturing process technology, applied in the field of rubber material preparation, can solve the problems of reducing process, reducing energy consumption, and not optimizing the corrosion resistance of rubber, etc., to achieve the goal of increasing crosslinking density, increasing service life, and improving self-elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

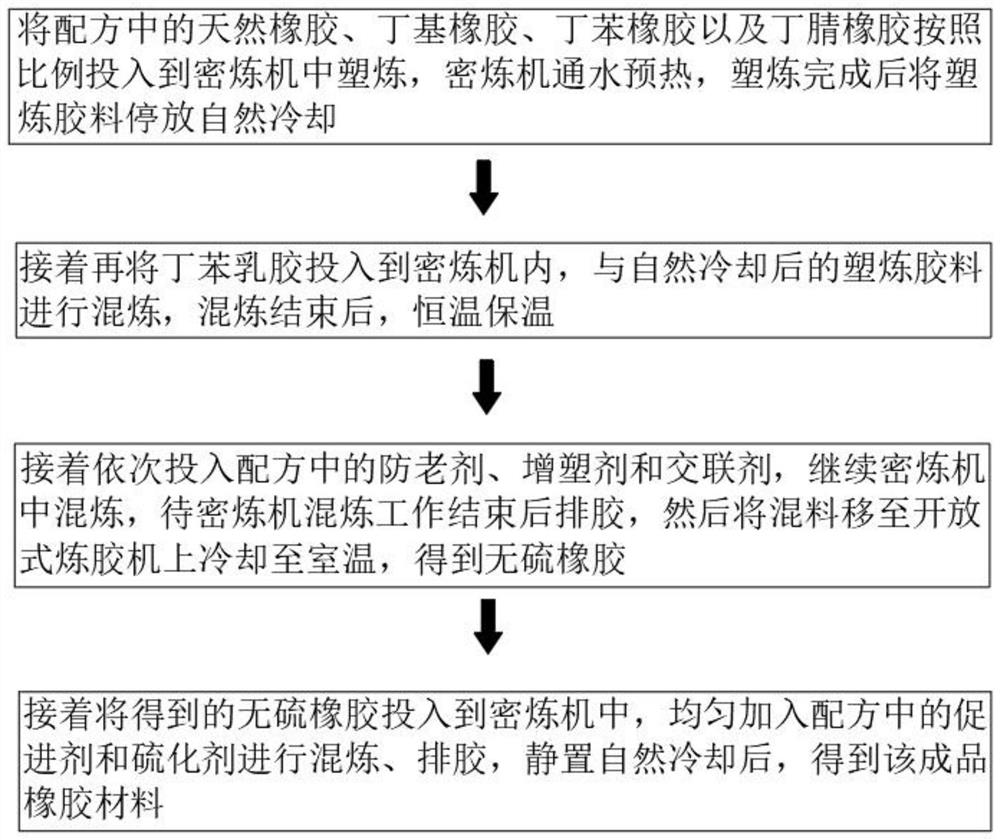

[0026] see figure 1 , the present invention provides a technical solution: a rubber material for making dumbbells is made of natural rubber, butyl rubber, styrene-butadiene rubber, nitrile rubber, anti-aging agent, accelerator, styrene-butadiene latex, vulcanizing agent, plasticizer and cross-linking agent. Joint agent composition, and the mass fraction of each component is as follows: natural rubber 58%, butyl rubber 13%, styrene-butadiene rubber 8%, nitrile rubber 8%, antioxidant 2%, accelerator 0.5%, styrene-butadiene latex 7% %, vulcanizing agent 1%, plasticizer 0.5% and crosslinking agent 2%.

[0027] The material of the anti-aging agent is one or two of anti-aging agent D, anti-aging agent RD and anti-aging agent MB. Using anti-aging agent D, anti-aging agent RD and anti-aging agent MB as anti-aging agent is not only non-toxic and harmless, but also can greatly improve The service life of rubber products, the material of the accelerator is one or more of zinc diethyl di...

Embodiment 2

[0034] see figure 1 , a rubber material for making dumbbells is composed of natural rubber, butyl rubber, styrene-butadiene rubber, nitrile rubber, anti-aging agent, accelerator, styrene-butadiene latex, vulcanizing agent, plasticizer and crosslinking agent, and each component The mass fractions are as follows: 60% natural rubber, 12% butyl rubber, 8% styrene-butadiene rubber, 7% nitrile rubber, 2% anti-aging agent, 1% accelerator, 6% styrene-butadiene latex, 1.5% vulcanizing agent, Plasticizer 1% and crosslinker 1.5%.

[0035]The material of the anti-aging agent is one or two of anti-aging agent D, anti-aging agent RD and anti-aging agent MB. Using anti-aging agent D, anti-aging agent RD and anti-aging agent MB as anti-aging agent is not only non-toxic and harmless, but also can greatly improve The service life of rubber products, the material of the accelerator is one or more of zinc diethyl dithiocarbamate, zinc dibutyl dithiocarbamate and zinc dimethyl dithiocarbamate, th...

Embodiment 3

[0042] see figure 1 , a rubber material for making dumbbells is composed of natural rubber, butyl rubber, styrene-butadiene rubber, nitrile rubber, anti-aging agent, accelerator, styrene-butadiene latex, vulcanizing agent, plasticizer and crosslinking agent, and each component The mass fractions are as follows: natural rubber 56.5%, butyl rubber 13%, styrene-butadiene rubber 8%, nitrile rubber 8%, antioxidant 2%, accelerator 1%, styrene-butadiene latex 7%, vulcanizing agent 1.5%, Plasticizer 1% and crosslinker 2%.

[0043] The material of the anti-aging agent is one or two of anti-aging agent D, anti-aging agent RD and anti-aging agent MB. Using anti-aging agent D, anti-aging agent RD and anti-aging agent MB as anti-aging agent is not only non-toxic and harmless, but also can greatly improve The service life of rubber products, the material of the accelerator is one or more of zinc diethyl dithiocarbamate, zinc dibutyl dithiocarbamate and zinc dimethyl dithiocarbamate, the vu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com