Supercharger sealing ring and preparation method thereof

A sealing ring and supercharger technology, applied in the field of sealing, can solve the problems of low service life, easy aging mechanical properties, etc., and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

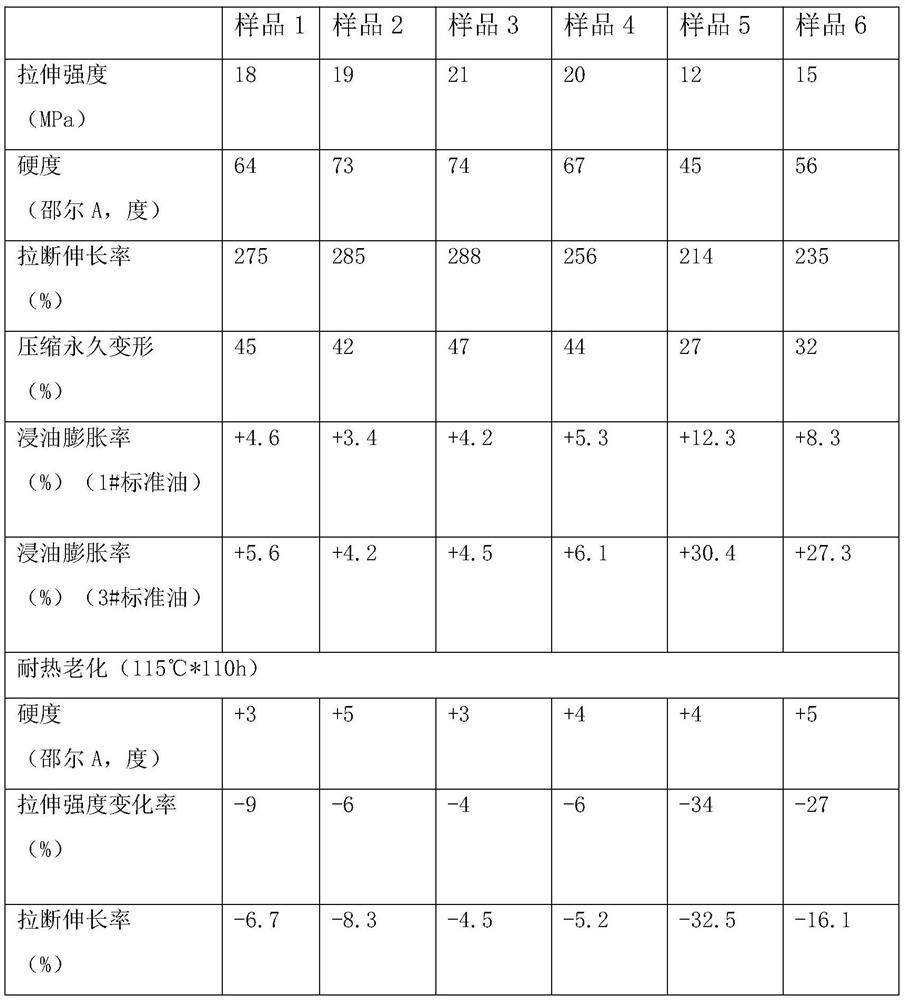

Examples

Embodiment 1

[0022] This embodiment provides a supercharger sealing ring, and its raw material formula is as follows:

[0023] 100 parts of nitrile rubber, 80 parts of fluorine rubber, 60 parts of carbon black, 30 parts of barium sulfate, 30 parts of talcum powder, 20 parts of graphene, 15 parts of magnesium oxide, 6 parts of magnesium stearate, N-phenyl-2- 2 parts of naphthylamine, 3 parts of N-phenyl-N'-isopropyl-p-phenylenediamine, 5 parts of sulfur, and 10 parts of N,N'-m-phenylene bismaleimide.

[0024] The preparation method is as follows:

[0025] S1: Mix nitrile rubber, fluororubber and carbon black in proportion for one stage of mixing, control the mixing temperature at 150-160°C for 10-15 minutes, and obtain P1;

[0026] S2: First, blend barium sulfate, talcum powder, graphene, magnesium oxide, magnesium stearate, and anti-aging agent according to the proportion. The mixing temperature is 100-130°C. After mixing for 5 minutes, add P1 and The vulcanizing agent is mixed in the se...

Embodiment 2

[0029] This embodiment provides a supercharger sealing ring, and its raw material formula is as follows:

[0030] 120 parts of nitrile rubber, 130 parts of fluororubber, 76 parts of carbon black, 45 parts of barium sulfate, 31 parts of talcum powder, 32 parts of graphene, 20 parts of magnesium oxide, 7 parts of magnesium stearate, N-phenyl-2- 5 parts of naphthylamine, 14 parts of N-phenyl-N'-isopropyl-p-phenylenediamine, 8 parts of sulfur, and 17 parts of N,N'-m-phenylene bismaleimide.

[0031] The preparation method is as follows:

[0032] S1: Mix nitrile rubber, fluororubber and carbon black in proportion for one stage of mixing, control the mixing temperature at 150-160°C for 13 minutes, and obtain P1;

[0033] S2: First, blend barium sulfate, talcum powder, graphene, magnesium oxide, magnesium stearate, and anti-aging agent according to the proportion. The mixing temperature is 100-130°C. After mixing for 8 minutes, add P1 and The vulcanizing agent is mixed in the second...

Embodiment 3

[0036] This embodiment provides a supercharger sealing ring, and its raw material formula is as follows:

[0037] 140 parts of nitrile rubber, 110 parts of fluororubber, 85 parts of carbon black, 42 parts of barium sulfate, 32 parts of talcum powder, 32 parts of graphene, 17 parts of magnesium oxide, 8 parts of magnesium stearate, N-phenyl-N` -8 parts of cyclohexyl-p-phenylenediamine, 9 parts of N-phenyl-2-naphthylamine, 15 parts of sulfur, and 20 parts of N,N'-m-phenylene bismaleimide.

[0038] The preparation method is as follows:

[0039] S1: Mix nitrile rubber, fluororubber and carbon black in proportion for one stage of mixing, control the mixing temperature at 150-160°C for 10-15 minutes, and obtain P1;

[0040] S2: First, blend barium sulfate, talcum powder, graphene, magnesium oxide, magnesium stearate, and anti-aging agent according to the proportion. The mixing temperature is 100-130°C. After mixing for 5-10 minutes, add it when the temperature rises to 210°C P1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com