Preparation method of organic pigment with high covering power and light fastness reaching grade 7 or above and applied to coating

An organic pigment and covering power technology, applied in the field of organic pigments, can solve the problems of difficult uniform dispersion, poor bonding, poor covering power, etc., and achieve the effect of good light fastness and stable azo bond performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a technical solution: a method for preparing an organic pigment with high hiding power and light fastness reaching grade 7 or above for coatings. The preparation steps are as follows:

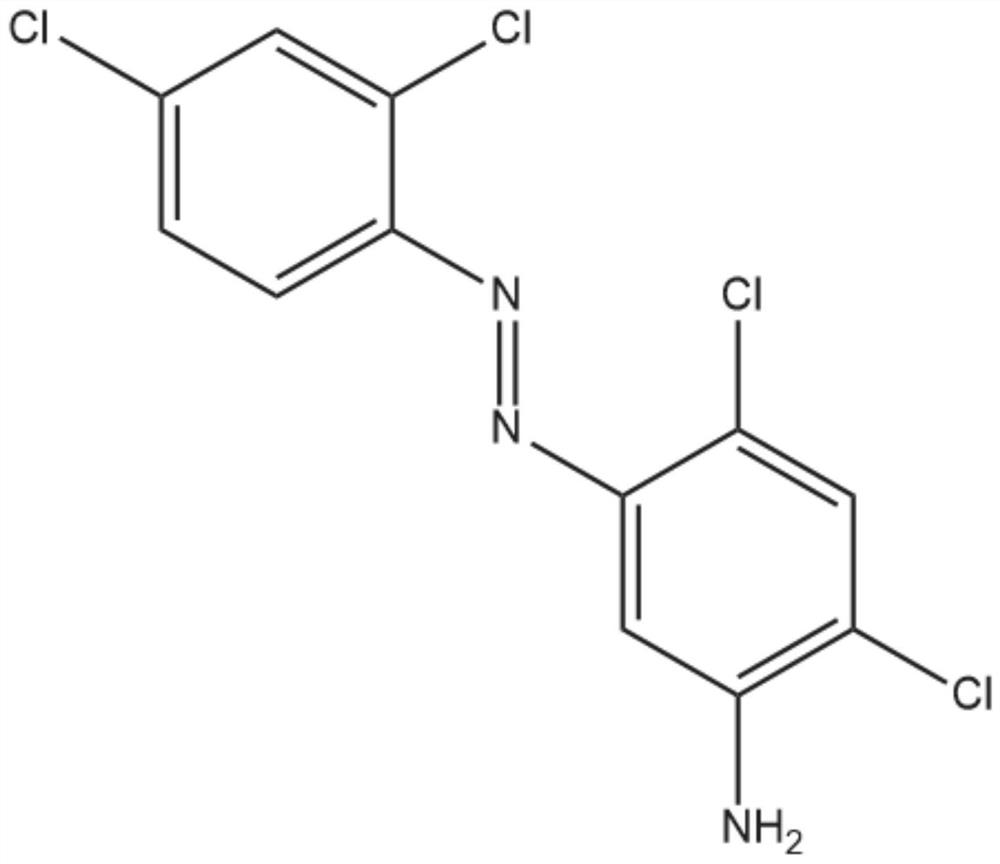

[0040] Step 1: Add 30 L of distilled water to a reaction vessel with a stirring and temperature control function in a capacity of 100 L, control the temperature of the distilled water to 3° C., then add 9 L of concentrated hydrochloric acid aqueous solution with a mass concentration of 38.3% and Stir, and when the temperature drops to 3°C, add 6.48kg of 2,4-dichloroaniline to the reaction vessel, and stir at a constant temperature until the 2,4-dichloroaniline is completely dissolved to obtain a reaction solution B;

[0041] Step 2: Slowly add 41.4 kg of 10% sodium nitrite aqueous solution to the reaction solution B at 3° C., and react for 30 minutes to obtain 83 L of reaction solution C;

[0042] Step 3: add 50L of 5% sodium hydroxide aqueous solution into a rea...

Embodiment 2

[0045] This embodiment provides a technical solution: a method for preparing an organic pigment with high hiding power and light fastness reaching grade 7 or above for coatings. The preparation steps are as follows:

[0046] Its main preparation steps are the same as in Example 1. Only in step 2, slowly add 60 kg of 10% sodium nitrite aqueous solution at a mass concentration of 10% to the reaction solution B in step 2, and react for 30 minutes to obtain 85 L of reaction solution C. Obtain the finished organic pigment of 11.5kg in step 4.

Embodiment 3

[0048] This embodiment provides a technical solution: a method for preparing an organic pigment with high hiding power and light fastness reaching grade 7 or above for coatings. The preparation steps are as follows:

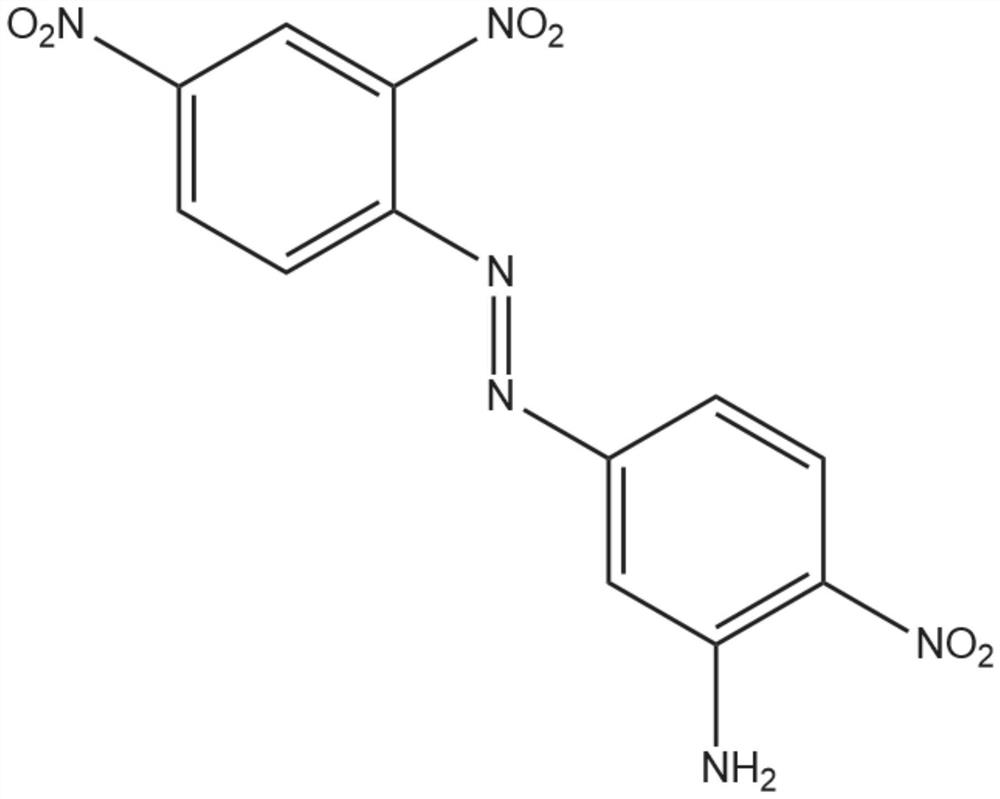

[0049] Step 1: Add 30 L of distilled water to a reaction vessel with a stirring and temperature control function in a capacity of 100 L, control the temperature of the distilled water to 3° C., then add 9 L of concentrated hydrochloric acid aqueous solution with a mass concentration of 38.3% and Stir, and when the temperature drops to 3°C, add 11 kg of 2,4-dinitroaniline to the reaction vessel, and stir at a constant temperature until the 2,4-dinitroaniline is completely dissolved to obtain a reaction solution B;

[0050] Step 2: Slowly add 49.7 kg of 10% sodium nitrite aqueous solution to the reaction solution B at 3°C, and react for 30 minutes to obtain 91 L of reaction solution C;

[0051] Step 3: Add 50L of 5% sodium hydroxide aqueous solution into a reaction v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com