A method for preparing ferrate based on carbon sheet iron plating

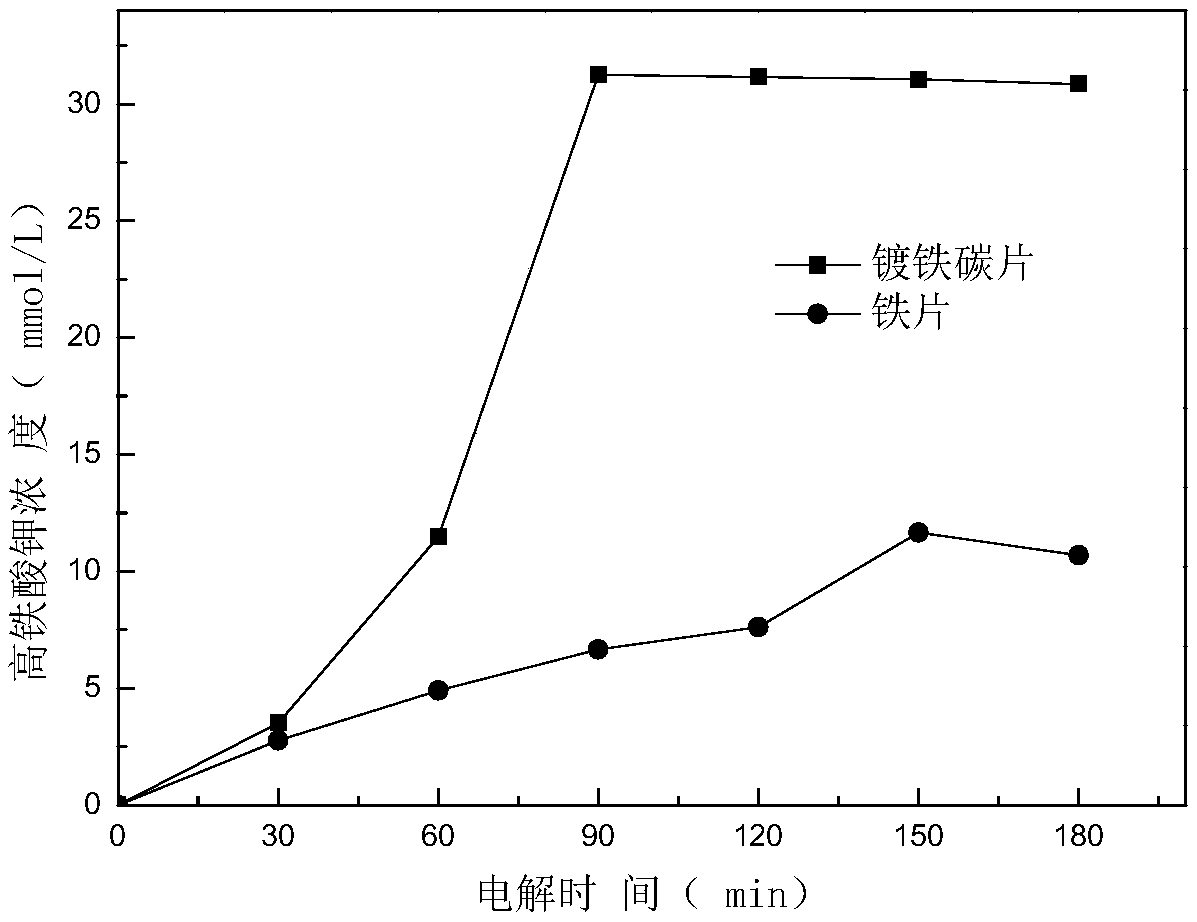

A technology of ferrate and iron plating, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of complex operation procedures, difficult production scale, large energy consumption, etc., achieve high activity performance, increase yield, improve The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

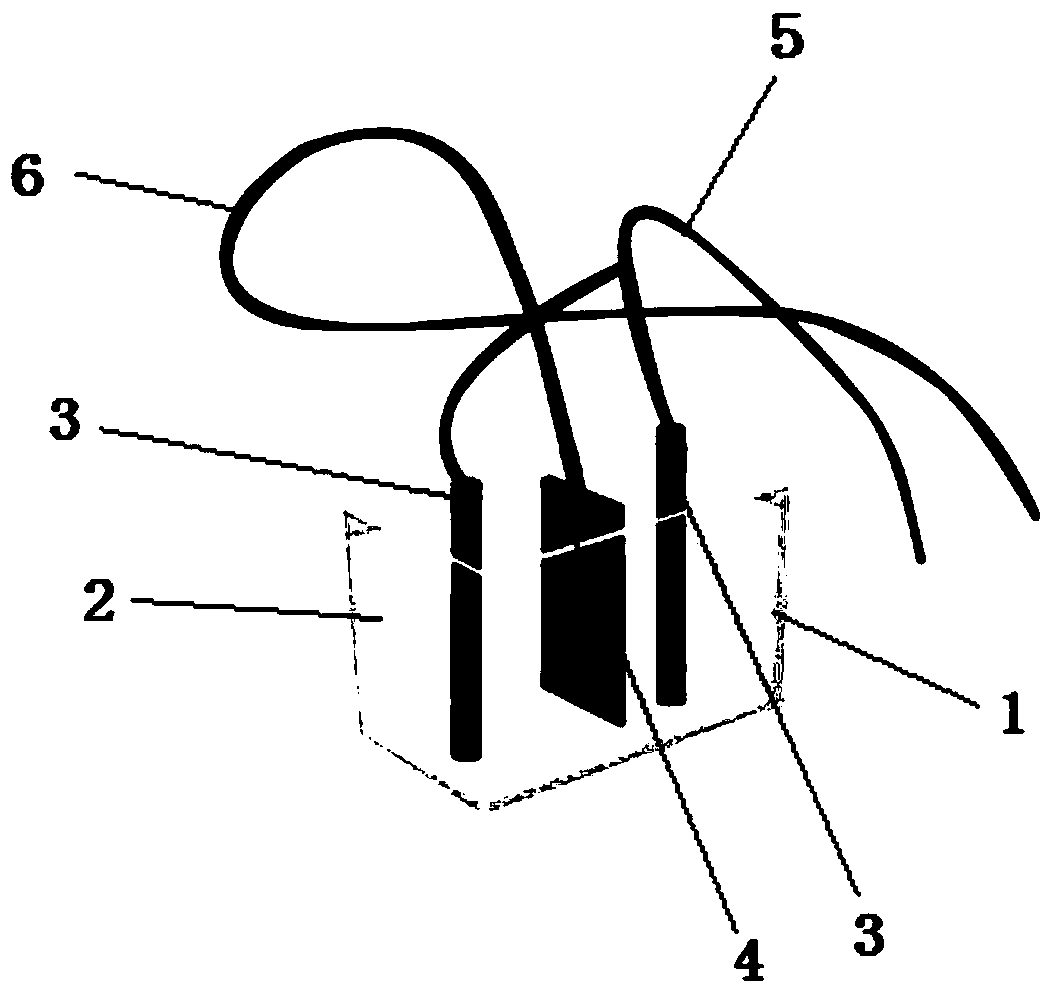

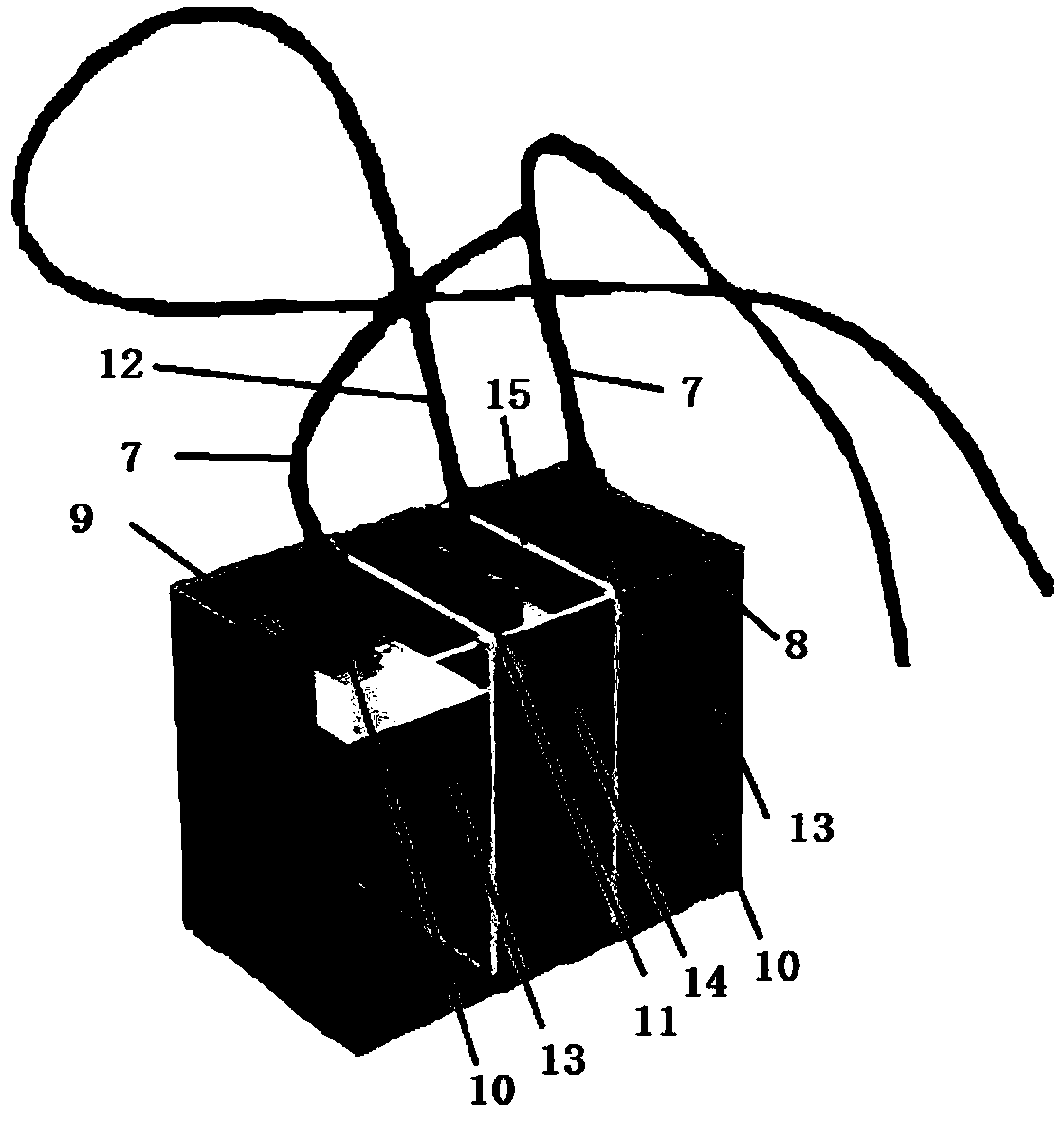

[0028] Step 1. Preparation of carbon sheet containing iron coating: select the electroplating solution formula: every liter of electroplating formula contains 50-600g ferrous chloride, 2-50g sodium chloride, 0-5g manganese chloride, 0-10g boric acid, The balance is water, preferably, each liter of electroplating formula contains 350g ferrous chloride, 10g sodium chloride, 1g manganese chloride, 5g boric acid, and the balance is water; the temperature is controlled at 25-40°C, and the pH is controlled at 1 -2 or so, the preparation of electroplating solution The present invention adopts the double anode electroplating method, selects rough carbon sheet with pits and cracks on the surface as the iron plating cathode, and the electroplating current density is 10A / dm 2 , electroplating apparatus such as figure 1 As shown, the electroplating device includes an electroplating tank 1, an electroplating solution 2 is contained in the electroplating tank 1, an anode carbon rod 3 is re...

Embodiment 1

[0032] A method for preparing ferrate based on carbon sheet iron plating, comprising the following steps:

[0033] Step 1, the preparation of the carbon sheet that contains iron coating: select electroplating solution formula: contain 350g ferrous chloride, 10g sodium chloride, 1g manganese chloride, 5g boric acid in every liter electroplating formula, surplus is water; Control temperature at 35°C, pH is controlled at about 1.5, and the electroplating solution is prepared. This invention adopts the double anode electroplating method, and selects a rough carbon sheet with pits and cracks on the surface as the iron plating cathode, and the electroplating current density is 10A / dm 2 , electroplating apparatus such as figure 1 As shown, the electroplating device includes an electroplating tank 1, an electroplating solution 2 is contained in the electroplating tank 1, an anode carbon rod 3 is respectively placed in the electroplating solution 2 and at both ends of the electroplati...

Embodiment 2

[0037] A method for preparing ferrate based on carbon sheet iron plating, comprising the following steps:

[0038] Step 1, the preparation of the carbon sheet that contains iron coating: select electroplating solution formula: contain 50g ferrous chloride, 50g sodium chloride, 0g manganese chloride, 10g boric acid in every liter of electroplating formula, surplus is water, control temperature at 25°C, pH control at 2, preparation of electroplating solution This invention adopts double anode electroplating method, selects rough carbon sheet with pits and cracks on the surface as iron plating cathode, and the electroplating current density is 10A / dm 2 , electroplating apparatus such as figure 1 As shown, the electroplating device includes an electroplating tank 1, an electroplating solution 2 is contained in the electroplating tank 1, an anode carbon rod 3 is respectively placed in the electroplating solution 2 and at both ends of the electroplating tank 1, and two anode rods 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com