Rubber paste material of rubber roller and preparation method of rubber paste material

A technology of glue and rubber roller, which is applied in the field of rubber roller glue material and its preparation, can solve the problems of easy occurrence of glue particles, easy occurrence of glue particles, easy occurrence of glue agglomeration, etc., so as to improve the adhesion of the glue layer The effect of compactness, improving metal surface activity, increasing surface tension and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

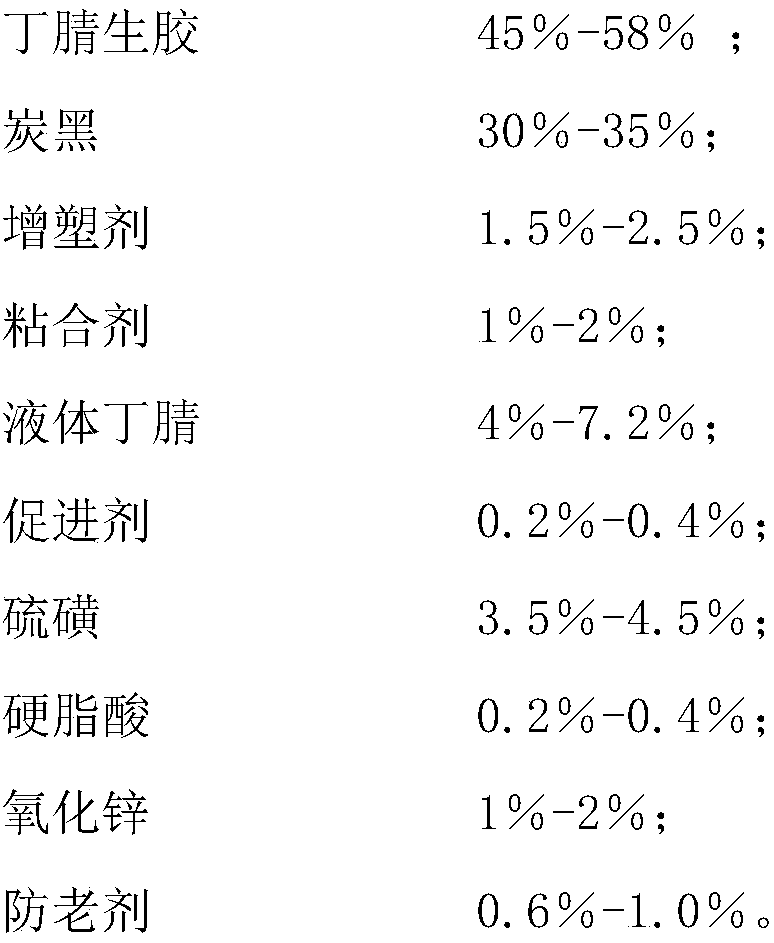

[0045] A kind of glue roller mortar material and its preparation method in this embodiment, producing 5 pieces of rubber rollers with a specification of Φ300×1600, composed of nitrile rubber compound and ethyl acetate components, the glue concentration is 10%, selected The gross weight of component is 75kg, and its nitrile rubber compound is made up of following weight percent component:

[0046]Composition weight percent:

[0047]

[0048]

[0049] Above-mentioned material adopts following preparation method to prepare, and its steps are as follows:

[0050] 1) One stage of mixing to make masterbatch, nitrile raw rubber is masticated on the open mill for 3 minutes to form, put into the internal mixer for 0.5 minutes to masticate, and then add high wear-resistant carbon black, mixed gas carbon black, white carbon black, Mix liquid nitrile and plasticizer TP-95 for 1.5 minutes, raise the bolt twice, add zinc oxide, stearic acid and anti-aging agent, mix for 1 minute, rai...

Embodiment 2

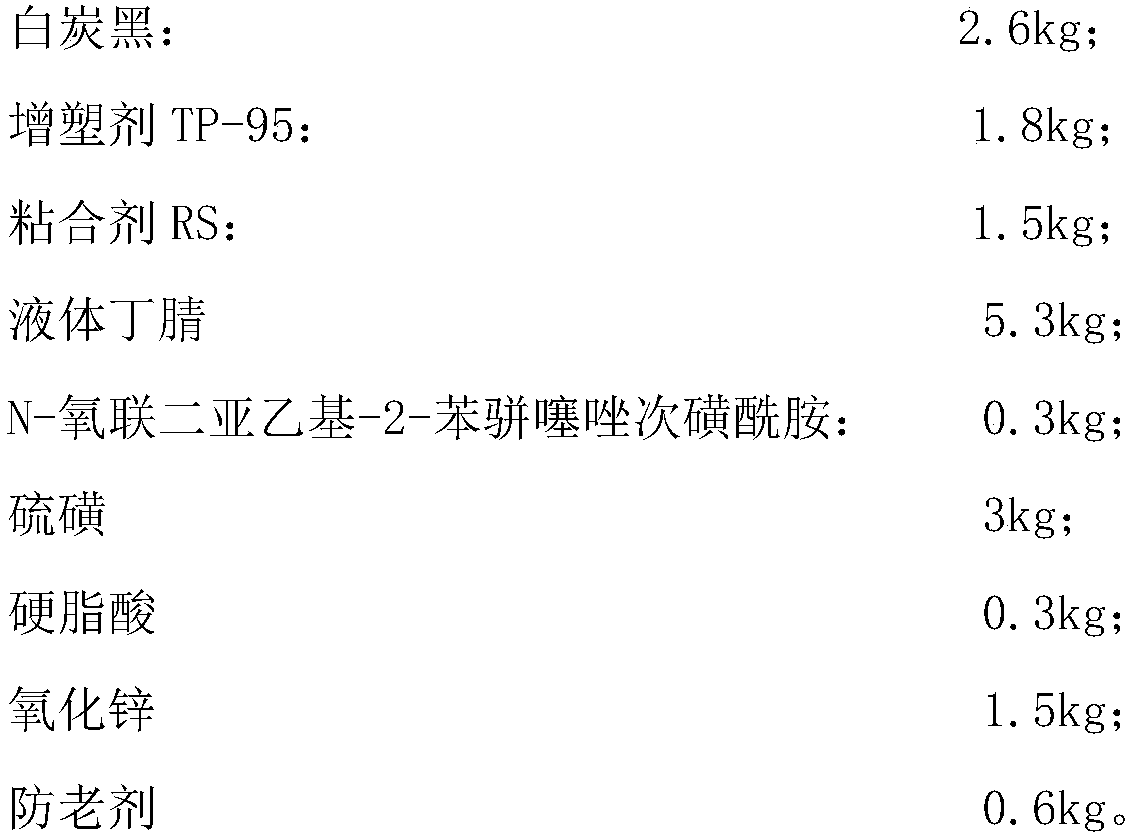

[0065] Adopt a kind of rubber roller glue material and preparation method thereof of this embodiment, produce 5 pieces of rubber rollers whose specifications are Φ800×1800, which are composed of nitrile rubber compound and ethyl acetate components, and the glue concentration is 12.5%. The total weight of selected components is 75kg, and its nitrile rubber compound is made up of following weight percent components:

[0066] Composition weight percent:

[0067]

[0068]

[0069] Adopt the above-mentioned composition and the material of percentage content, preparation method is as follows:

[0070] 1) One stage of mixing to make masterbatch, nitrile raw rubber is masticated on the open mill for 4 minutes to form, put into the internal mixer for 0.5 minutes to masticate, and then add high wear-resistant carbon black, mixed gas carbon black, white carbon black, Mix liquid nitrile and plasticizer TP-95 for 1.5 minutes, raise the bolt twice, add zinc oxide, stearic acid and an...

Embodiment 3

[0082] Adopt a kind of rubber roller mortar material and preparation method thereof of the present embodiment, produce 5 rubber rollers whose specifications are Φ1500×1700, which are composed of nitrile rubber compound and ethyl acetate components, and the glue concentration is 15%. The total weight of selected components is 75kg, and its nitrile rubber compound is made up of following weight percent components:

[0083] Composition weight percent:

[0084]

[0085] Adopt the above-mentioned composition and the material of percentage content, preparation method is as follows:

[0086] 1) One stage of mixing to make masterbatch. After the nitrile raw rubber is masticated on the open mill for 5 minutes to form, it is put into the internal mixer for 1 minute of mastication, and the wear-resistant carbon black, mixed gas carbon black, and white carbon black are added in sequence. Mix liquid nitrile and plasticizer TP-95 for 2 minutes, raise the bolt twice, add zinc oxide, stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com