Control method for efficient utilization of waste heat of sintering circular cooler

A technology of sintering ring cooler and control method, which is applied in the direction of furnace control device, waste heat treatment, and treatment of discharged materials, etc., which can solve the problems of analysis and judgment, and cannot make parameter adjustments in time, so as to reduce the power consumption of fans and improve cooling efficiency , beneficial to the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

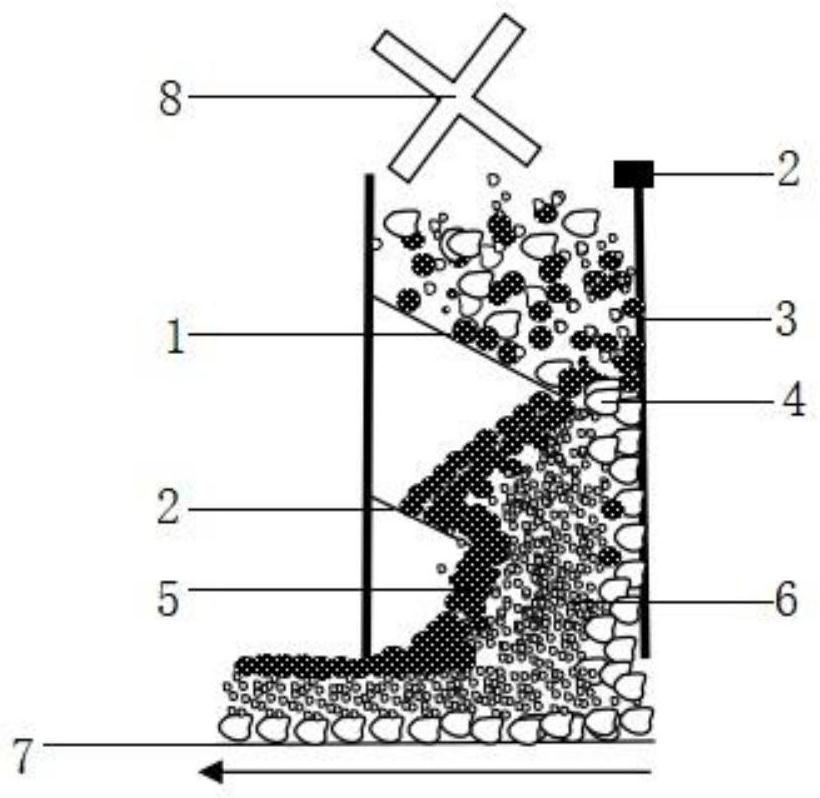

[0017] The present invention is described in further detail now in conjunction with accompanying drawing.

[0018] Such as figure 1 As shown, a control method for efficient utilization of waste heat of sintering ring cooler includes the following steps:

[0019] 1) The hot sintered ore is segregated on the ring cooling trolley 7 under the action of the material guide plate 1 through the hot ore chute;

[0020] 2) The particle size distribution of hot sinter on the annular cooler is as follows: the lowermost layer of the annular cooler is dominated by large particle 4 sinter, the middle layer is dominated by small particle 6, and the uppermost layer is dominated by intermediate grade 5 sinter;

[0021] 3) The position and angle of the material guide plate 1 are closely related to the height of the hot ore chute 3, generally forming an angle of 40-60° with the side wall angle of the hot ore chute;

[0022] 4) A high temperature resistant camera 2 can be installed on the side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com