Preparation method of copper-clad steel bimetal composite wire

A composite wire and bimetallic technology, which is applied in the direction of cable/conductor manufacturing, wire harness manufacturing, electrical components, etc., can solve problems such as emissions, insufficient comprehensive performance of wires, and polluted waste liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

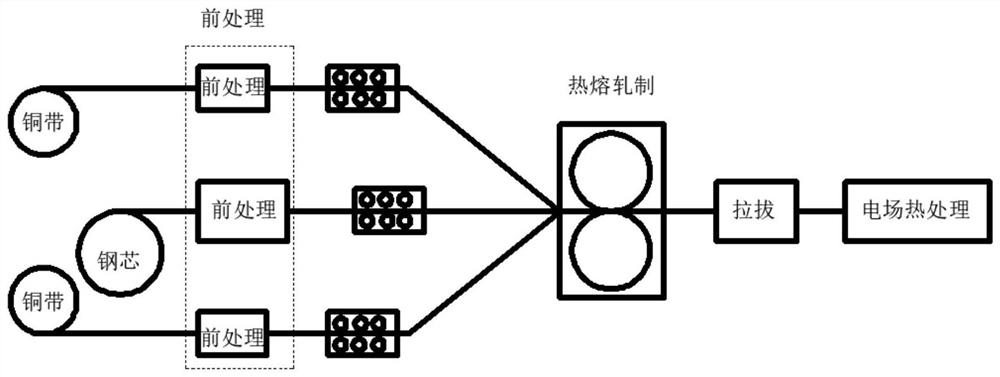

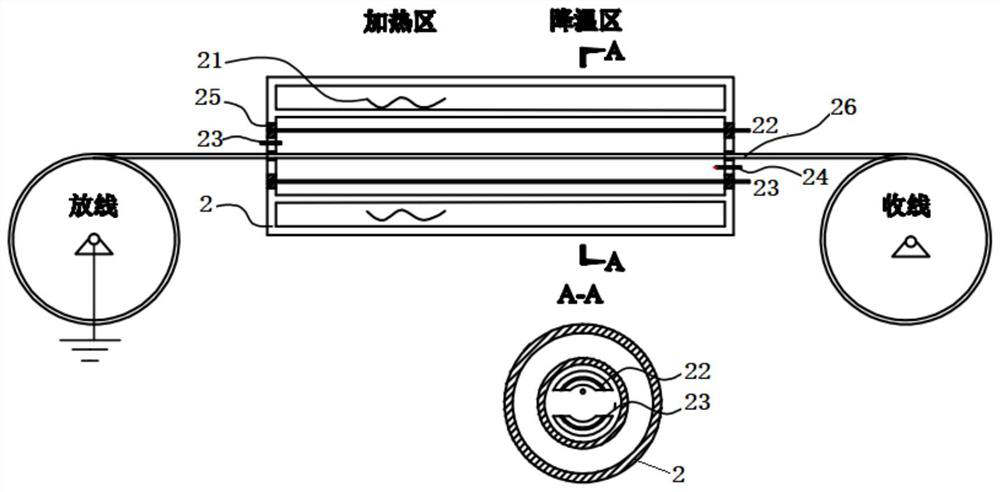

[0040] Such as figure 1 The illustrated embodiment is a method for preparing a copper-clad steel bimetallic composite wire, comprising the steps of:

[0041] Pre-treatment: mechanical derusting and peeling, pre-drawing, setting-out and grinding, ultrasonic cleaning (water medium), drying and plasma cleaning for steel cores with a wire diameter of 6mm; ultrasonic cleaning (water medium) for copper strips, Drying and plasma cleaning to get clean steel core and copper strip;

[0042] The composition of the steel core composition is: 0.1%C, 0.4%Mn, 0.1%Si, 0.04%Nb, 0.05%V, 0.005%B, 0.1%Ce, 0.5Nd, S%<0.004%, P%<0.006, I The amount is Fe; the average grain size of the steel core is 5μm.

[0043] The composition of the copper strip is: 99.99% Cu, 0.003% O, and the rest are impurities; the average grain size of the copper strip is 20 μm.

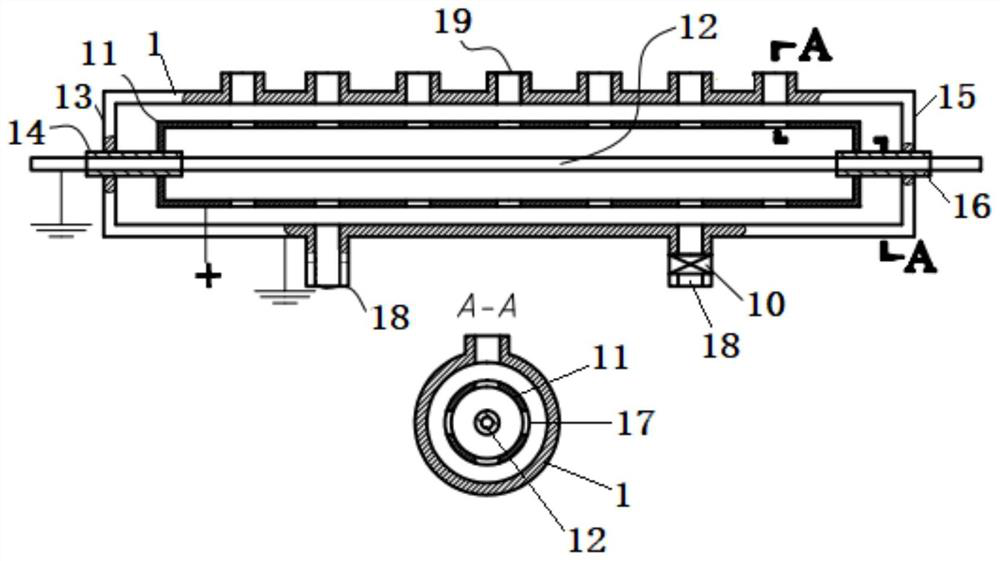

[0044] Also includes such as figure 2 In the plasma cleaning device shown, the steel core and the copper strip are plasma cleaned by the plasma ...

Embodiment 2

[0060] The composition of steel core composition is: 0.2%C, 0.8%Mn, 0.15%Si, 0.03%Nb, 0.04%V, 0.004%B, 0.2%Nd, S%<0.005%, P%<0.01, the balance is Fe ; The average grain size of the steel core composition is 3 μm.

[0061] The composition of the copper strip composition is: 99.99% Cu, 0.002% O content, and the rest are impurities; the average grain size of the copper strip composition is 50 μm.

[0062] In Embodiment 2, the process of plasma cleaning the steel core with a wire diameter of 6.5mm by using a plasma cleaning device is as follows:

[0063] Close the intake valves of the plasma cleaning device, and make the vacuum pump work to evacuate the vacuum chamber to 1×10 -1 Pa;

[0064] Open each intake valve, pass in argon gas from each intake port, adjust the opening of the vacuum valve, and continue to work the vacuum pump to make the air pressure in the vacuum chamber reach 20Pa;

[0065] Turn on the power supply of the tubular anode (Wuyuan Electrical Equipment Co., L...

Embodiment 3

[0077] The composition of the steel core is: 0.03%C, 0.1%Mn, 0.12%Si, 0.04%Nb, 0.02V%, 0.004%B, 0.2%Pr, S%<0.003%, P%<0.005, and the rest is Fe; The average grain size of the steel core is 5 μm.

[0078] The composition of the copper strip is: 99.95% Cu, 0.003% O content, and the rest are impurities; the average grain size of the copper strip is 40 μm.

[0079] In Embodiment 3, the process of plasma cleaning the steel core with a wire diameter of 7.3mm by using a plasma cleaning device is as follows:

[0080] Close the intake valves of the plasma cleaning device, and make the vacuum pump work to evacuate the vacuum chamber to 1×10 -2 Pa;

[0081] Open each intake valve, feed krypton gas from each intake port, adjust the opening of the vacuum valve, and the vacuum pump continues to work, so that the air pressure in the vacuum chamber reaches 40Pa;

[0082] Turn on the power supply of the tubular anode (Wuyuan Electrical Equipment Co., Ltd., model: MSB-100K), set the power freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com