Hard carbon material precursor, pre-carbonized product, hard carbon material, secondary battery, preparation method and application

A technology for hard carbon pre-carbonized products and secondary batteries, which is applied in the preparation/purification of carbon, battery electrodes, circuits, etc., can solve the problems of high energy consumption cost, insufficient electrochemical performance of battery products, and complicated preparation methods. Low energy cost, excellent electrochemical performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

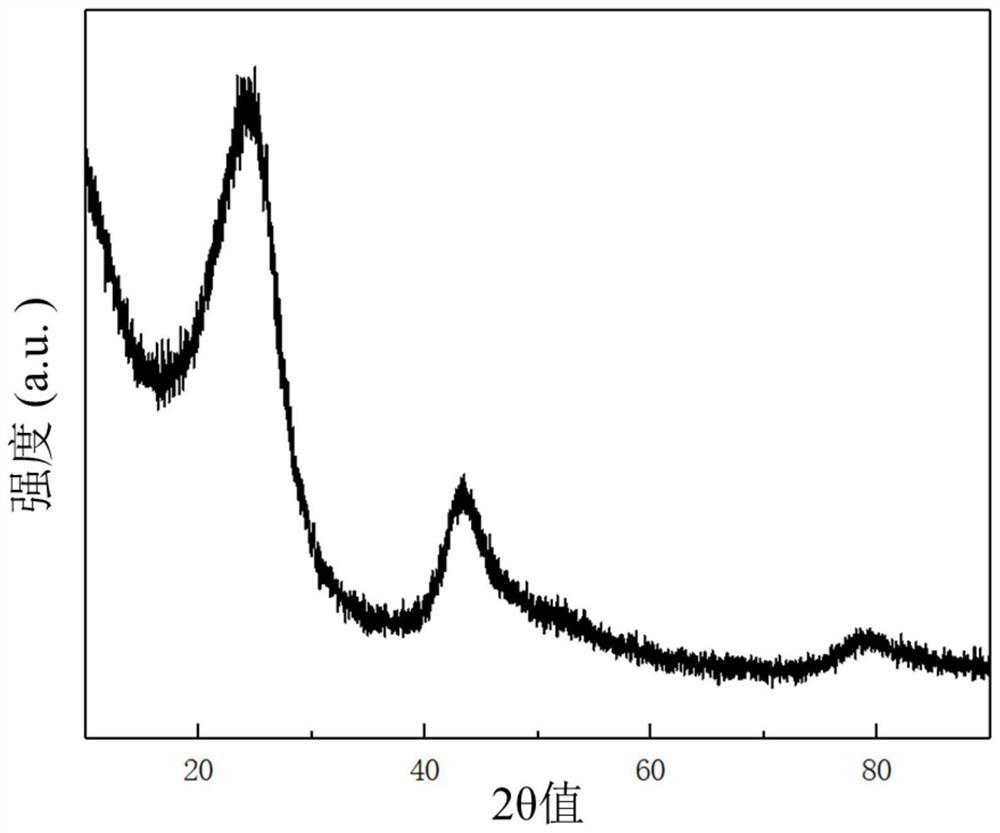

Image

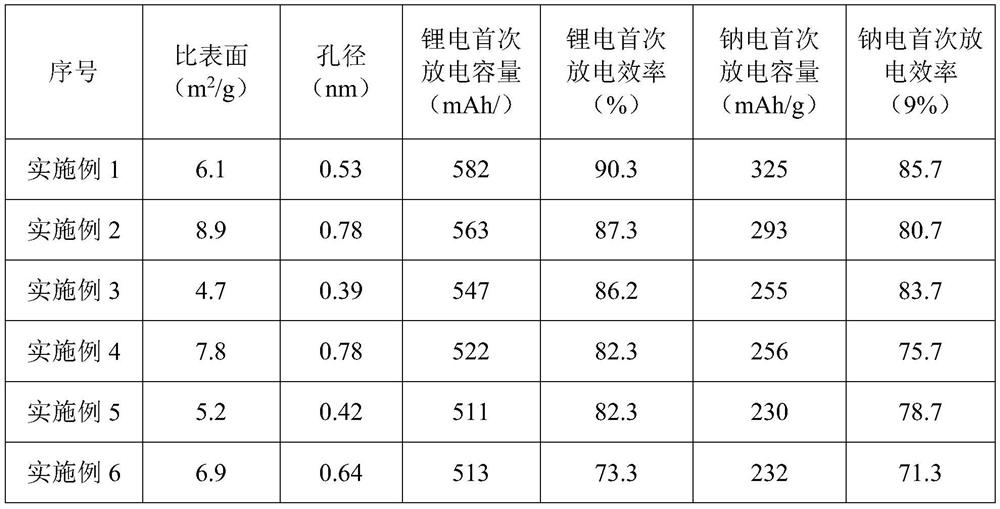

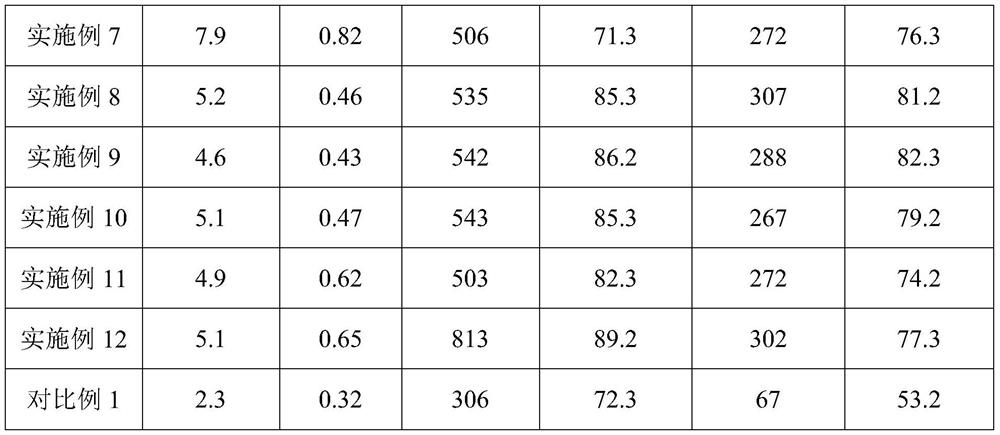

Examples

Embodiment 1

[0039] (1) Preparation of hard carbon material precursor

[0040] Dissolve 50 g of coumarone resin in 100 g of chloroform solution, add 5 g of AlCl to the resulting solution 3 (coumarone resin and chloroform mass ratio are 0.5, AlCl 3 The mass ratio to coumarone resin is 0.1), and stirred and reacted in a water bath at 60° C. for 24 hours. After the reaction is finished, the generated precipitate is filtered, washed and dried to obtain a hard carbon material precursor.

[0041] (2) Preparation of pre-carbonized products of hard carbon materials

[0042] Pre-carbonize the hard carbon material precursor obtained in step (1) in a well-type furnace under nitrogen protection. The pre-carbonization temperature is 600° C. and the pre-carbonization time is 4 hours to obtain a hard carbon material pre-carbonized product.

[0043] (3) Preparation of hard carbon materials

[0044] The hard carbon material pre-carbonized product obtained in step (2) is carbonized in a tube furnace und...

Embodiment 2

[0047] In embodiment 1, coumarone resin is replaced by epoxy resin, and other conditions and operations are all the same.

Embodiment 3

[0049] In Example 1, the coumarone resin was replaced with mesophase pitch, and other conditions and operations were unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com