Sodium-ion battery positive electrode material with multi-core type core-shell structure and preparation method of sodium-ion battery positive electrode material

A sodium-ion battery, core-shell structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as non-uniformity of performance indicators, failure to meet expectations, etc., to improve cycle performance, reduce the possibility of collapse, Reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

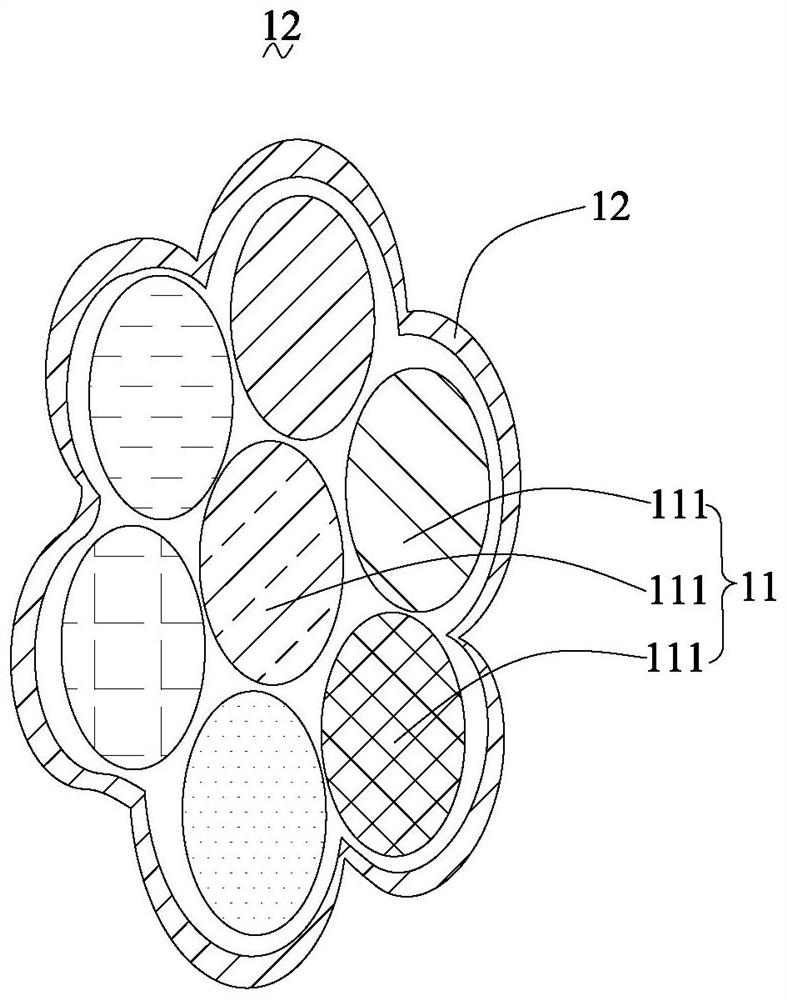

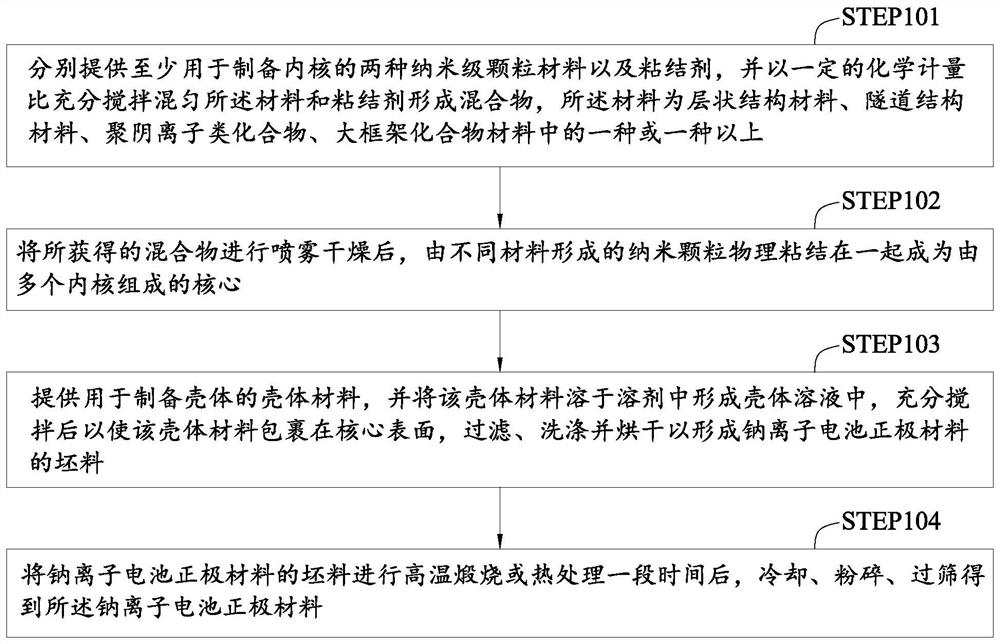

[0033] Such as figure 2 Shown, the present invention also provides a kind of preparation method of the sodium ion battery cathode material of described polynuclear core-shell structure, and it comprises the steps:

[0034] STEP101: Provide at least two kinds of nano-scale particle materials and binders for preparing the inner core 111 respectively, and fully stir and mix the nano-scale particle materials and the binder at a certain stoichiometric ratio to form a mixture, the nano-scale The granular material is one or more of layered structure materials, tunnel structure materials, polyanionic compounds, and macroframe compound materials;

[0035] STEP102: After the obtained mixture is spray-dried, nanoparticles formed of different materials are physically bonded together to form a core 11 composed of multiple inner cores 111;

[0036] STEP103: Provide the shell material for preparing the shell 12, and dissolve the shell material in a solvent to form a shell solution, stir we...

Embodiment 1

[0047] NaCu 0.4 Fe 0.3 mn 0.3 o 2 Sodium iron phosphate NaFePO with olivine structure 4 The nano-scale materials are fully mixed according to the stoichiometric ratio of 1:0.1. After spray drying and nucleation, they are dispersed in an ethanol solution containing aluminum isopropoxide with a concentration of 2.5wt.%. After continuous stirring for 3 hours, filter , washing and drying, calcining the obtained mixture at 400° C. for 8 hours in an argon atmosphere, and cooling to obtain a positive electrode material.

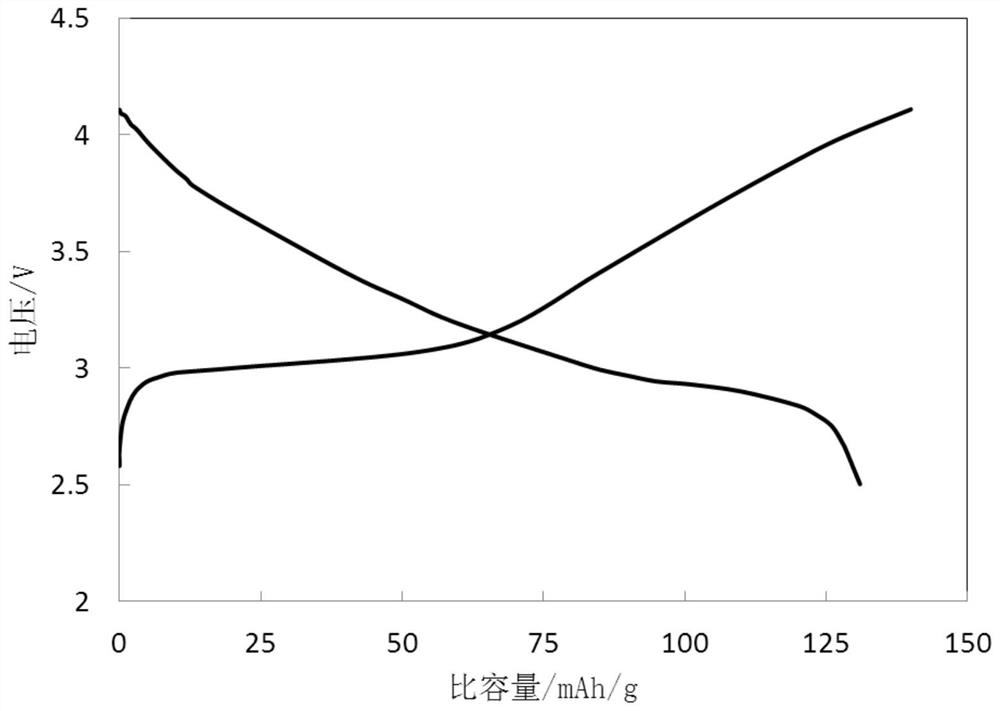

[0048] The electrochemical performance test of the material is tested at 25°C with the blue battery test system, and the test voltage range is 2.5V to 4.2V; the specific capacity test conditions: 0.1C charge and discharge once; 0.2C charge and discharge once; 0.2C charge, 1C discharge once, such as image 3 Shown; cycle performance test conditions: charge and discharge at a rate of 1C, cycle for 500 cycles, and investigate the capacity retention rate. The spec...

Embodiment 2

[0050] NaCu 0.4 Fe 0.3 mn 0.3 o 2 Polyanionic compounds with framework structure Na 3 V 2 (PO 4 ) 3The nano-scale materials are fully mixed according to the stoichiometric ratio of 1:0.2. After spray drying and nucleation, they are dispersed in an aluminum isopropoxide ethanol solution with a concentration of 5wt.%. After continuous stirring for 3 hours, filter, After washing and drying, the obtained mixture was calcined at 650° C. for 6 hours in an argon atmosphere, and then cooled to obtain a positive electrode material.

[0051] The electrochemical performance test of the material is tested at 25°C with the blue battery test system, and the test voltage range is 2.5V to 4.2V; the specific capacity test conditions: 0.1C charge and discharge once; 0.2C charge and discharge once; 0.2C charge, Discharge once at 1C; cycle performance test conditions: charge and discharge at a rate of 1C, cycle 500 cycles, and investigate the capacity retention rate. The specific discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com