Casting embedding material for dental cast porcelain and preparation method of casting embedding material

An embedding material, dental technology, used in dental preparations, dentistry, dental prostheses, etc., can solve problems such as mismatching expansion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare several raw materials such as ammonium dihydrogen phosphate, quartz, cristobalite, magnesium oxide and ammonium aluminum carbonate, and dry all raw materials at 90°C for 12h. Then, in a workshop with a humidity less than 30%, pass the dried ammonium dihydrogen phosphate through 200-mesh, 250-mesh, and 400-mesh sieves continuously. For feeding ammonium dihydrogen phosphate 250-mesh sieve and for ammonium dihydrogen phosphate 400-mesh sieve unloading; in a workshop with a humidity less than 30%, pass the dried quartz continuously through 250-mesh and 300-mesh sieves, and take 300-mesh The sieve material of the sieve is marked as quartz 300-mesh sieve material; in a workshop with a humidity less than 30%, the dried cristobalite is continuously passed through a 300-mesh sieve and a 400-mesh sieve, and the 400-mesh sieve material is taken. Marked as cristobalite 400-mesh sieve feeding; in a workshop with a humidity less than 30%, pass the dried magnesia through a 400...

Embodiment 2~5

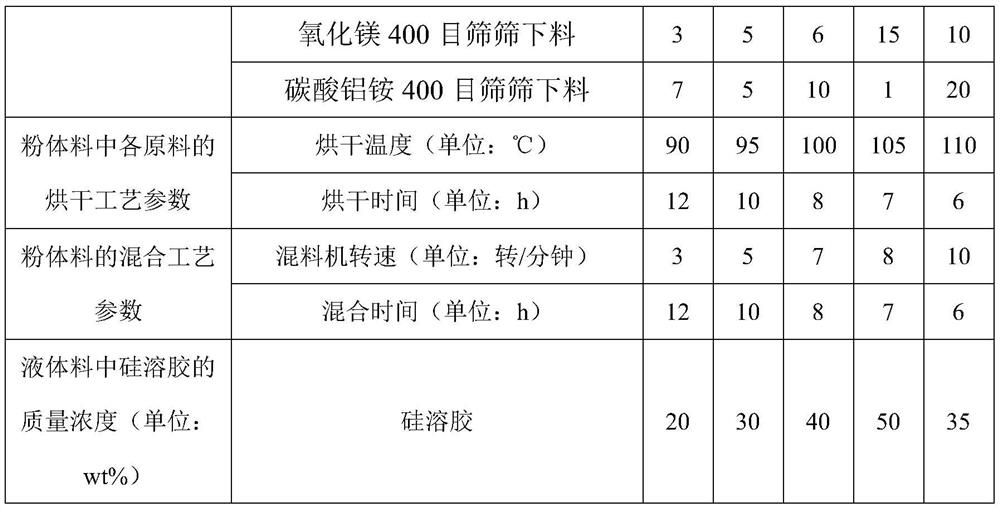

[0022] Examples 2-5 Prepare the embedding material for dental ceramic casting of the present invention, the preparation method is completely consistent with Example 1, wherein the mass ratio of each component in the powder material, the drying process parameters of each raw material in the powder material , powder material mixing process parameters, and the mass concentration of silica sol in the liquid material are shown in Table 1 for details.

[0023] Component design and preparation process parameters of the embedding material for dental casting porcelain in Table 1 Example 1-5

[0024]

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com