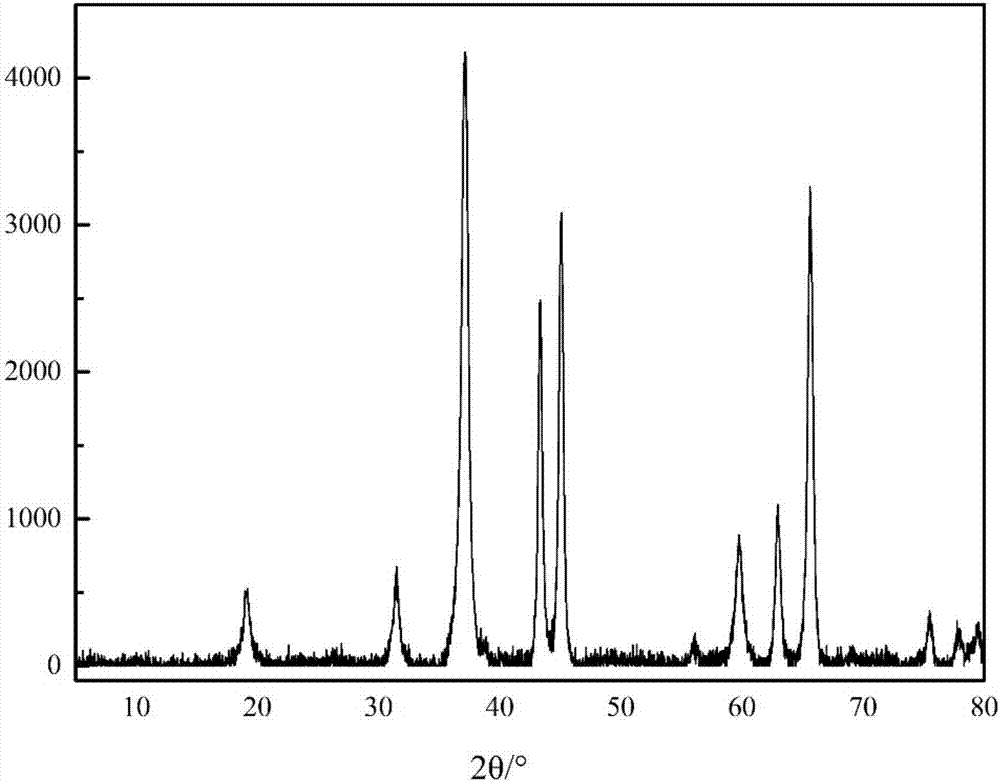

Method for preparing nano nickel oxide / nickel aluminum spinel oxygen carrier

An oxygen carrier and nanotechnology, which is applied in the field of material chemistry, can solve problems such as inability to effectively prepare microporous spinel powder, etc., and achieve the effects of low equipment requirements, simple production process technology, and easy process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

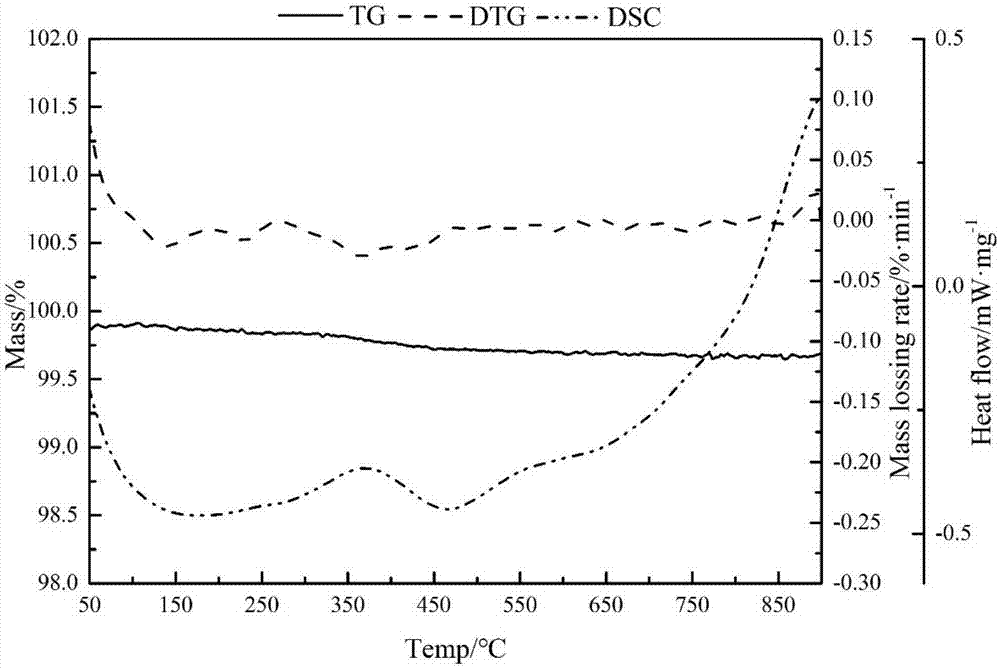

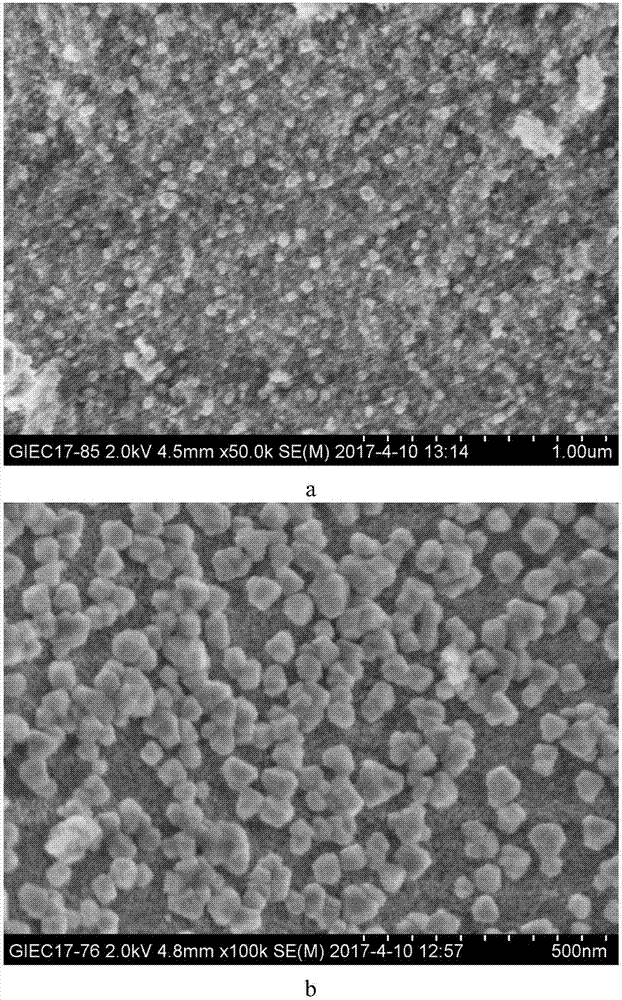

[0037] This embodiment provides a nano-NiO / NiAl 2 o 4 The preparation method of oxygen carrier, comprises the following steps:

[0038] 1) Prepare a nitrate solution with a Ni / Al molar ratio of 2.25, wherein the Ni ion content is 0.45 mol / L, and the Al ion content is 0.2 mol / L, and prepare 500 mL of the nitrate solution. Prepare 200 mL of ammonium carbonate solution with a concentration of 0.5 mol / L.

[0039] 2) Slowly add 0.5mol / L ammonium carbonate solution to the stirring nitrate solution. The amount of ammonium carbonate solution added is about 150mL, the pH is controlled at 5.0, and a paste-like hydrosol is formed. Continue stirring with a glass rod to form a Certainly viscous hydrosol.

[0040] 3) Slowly dry the hydrosol in a vacuum drying oven at 60°C for 12 hours, and keep the vacuum at -0.01MPa, and then age it at 80°C for 6 hours in an air atmosphere to form a dry colloid with a certain shape.

[0041] 4) Heat the dried colloid in a muffle furnace at 400° C. for 2 ...

Embodiment 2

[0048] This embodiment provides a nano-NiO / NiAl 2 o 4 The preparation method of oxygen carrier, comprises the following steps:

[0049] 1) Prepare a nitrate solution with a Ni / Al molar ratio of 2.25, wherein the Ni ion content is 0.45 mol / L, and the Al ion content is 0.2 mol / L, and prepare 700 mL of the nitrate solution. Prepare 500 mL of ammonium carbonate solution with a concentration of 1.0 mol / L.

[0050] 2) Slowly add 0.25mol / L ammonium carbonate solution to the stirring nitrate solution, the amount of ammonium carbonate solution added is about 300mL, the pH is controlled at 5.5, keep stirring until a paste-like suspension is formed, continue to use a glass rod Stir to form a viscous hydrosol.

[0051] 3) Slowly dry the hydrosol in a vacuum drying oven at 65°C for 10 hours, and keep the vacuum at -0.01MPa, and then age it at 90°C for 3 hours in an air atmosphere to form a dry colloid with a certain shape.

[0052] 4) Heat the dried colloid in a muffle furnace at 450° ...

Embodiment 3

[0055] This embodiment provides a nano-NiO / NiAl 2 o 4 The preparation method of oxygen carrier, comprises the following steps:

[0056] 1) Prepare a nitrate solution with a Ni / Al molar ratio of 2.25, in which the Ni ion content is 0.45 mol / L, and the Al ion content is 0.2 mol / L, and prepare 300 mL of the nitrate solution. Prepare 200 mL of ammonium carbonate solution with a concentration of 0.25 mol / L.

[0057] 2) Slowly add 0.25mol / L ammonium carbonate solution to the stirring nitrate solution, the amount of ammonium carbonate solution added is about 100mL, the pH is controlled at 4.5, keep stirring until a paste-like suspension is formed, continue to use a glass rod Stir to form a viscous hydrosol.

[0058] 3) Slowly dry the hydrosol in a vacuum drying oven at 50°C for 24 hours, and keep the vacuum at -0.01MPa, and then age it at 75°C for 8 hours in an air atmosphere to form a dry colloid with a certain shape.

[0059] 4) Heat the dried colloid in a muffle furnace at 350...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com