Synthesis method of captan or folpet

A synthesis method and folpet technology, which are applied in the synthesis of captan or folpet, and in the field of captan or folpet synthesis, can solve the problems of poor process stability, high environmental pressure, and easy damage. Achieve the effect of increasing environmental friendliness, increasing product yield, and reducing excessive dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

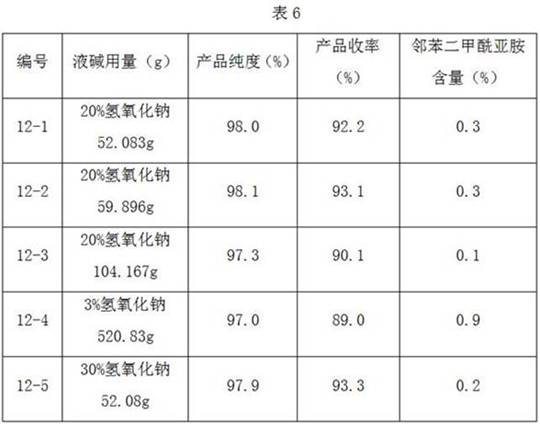

Embodiment 1

[0053] Take 31.50g of perchloromethanethiol (purity 96.80%, 0.164mol) and 25.0g of 1,2,3,6-tetrahydrophthalimide (purity 98.00%, 0.162mol) according to the molar ratio of 1.01:1. ). Take 100.00g 1,2-dichloroethane, 0.25g tetrabutylammonium bromide; mix perchloromethanethiol, 1,2,3,6-tetrahydrophthalimide, 1,2- Add dichloroethane and tetrabutylammonium bromide into the three-necked flask, stir evenly, then add 34.40g (0.172mol) of 20% sodium hydroxide solution dropwise at a controlled speed of 1000rpm and below 25°C, and the dropping time is 70-90min After the dropwise addition, keep warm for 30 minutes, then raise the temperature to 60°C and keep it purified for 1 hour, then cool down to room temperature after the keep warm, filter with suction, and wash to obtain 47.29 g (0.154 mol) of captan technical product. The purity of the product detected by HPLC is 97.89%. (i.e. 1,2,3,6-tetrahydrophthalimide, the same below) content of 0.50%, moisture content of 0.03%, sodium chlorid...

Embodiment 2

[0056] Captan was prepared according to the method of Example 1, except that the catalysts used were different, as shown in Table 1 below.

[0057]

Embodiment 3

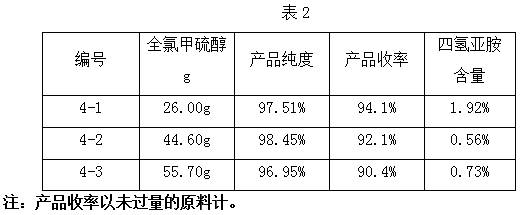

[0059] Take 33.50g of perchloromethanethiol (purity 96.80%, 0.174mol) and 1,2,3,6-tetrahydrophthalimide 30.00g (purity 98.00%, 0.194mol) according to the molar ratio of 0.9:1. ), take 120.00g of chlorobenzene according to 4 times the mass of 1,2,3,6-tetrahydrophthalimide, according to the mass of 1,2,3,6-tetrahydrophthalimide 0.5% Take 0.15g of tetrabutylammonium bromide, add them into the three-necked flask and stir evenly, then add 142.50g (0.103mol) of 10% potassium carbonate solution dropwise at a controlled speed of 2000 rpm and below 25°C, and the dropping time is 30 -50min, after the dropwise addition, keep warm for 60min, raise the temperature to 60°C and keep it purified for 1h, then cool down to room temperature at the end of the warming, filter with suction, and wash to get 50.40g (0.164mol) of captan technical product. The purity of the product detected by HPLC is 97.60%. The amine content is 0.60%, the moisture content is 0.02%, and the sodium chloride content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com