Spraying quick-setting rubber asphalt waterproof coating and preparation method thereof

A technology for quick-setting rubber asphalt and waterproof coatings, applied in asphalt coatings, natural rubber coatings, chemical instruments and methods, etc., can solve the problems of long surface dry and hard dry time, high construction requirements, and achieve short surface dry and hard dry time. The effect of simplifying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

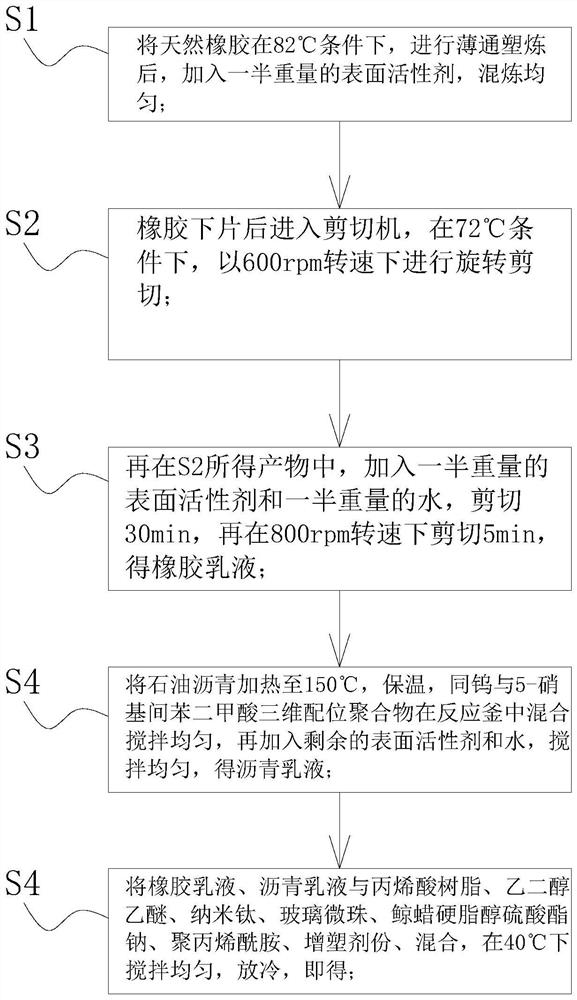

[0036] In this embodiment, spraying quick-setting rubber asphalt waterproof coating is provided, and the spraying quick-setting rubber asphalt waterproof coating is made of the following raw materials in parts by weight: the content of cis-1,4-polyisoprene is more than 95% 50 parts of natural rubber, 5 parts of three-dimensional coordination polymer of tungsten and 5-nitroisophthalic acid, 7 parts of acrylic resin, 4 parts of ethylene glycol ether, 10 parts of petroleum pitch, 1 part of nano-titanium, and 1 part of glass microspheres 2 parts, 2 parts of sodium cetearyl sulfate, 3 parts of polyacrylamide, 1 part of plasticizer, 2 parts of surfactant, 30 parts of water;

[0037] The three-dimensional coordination polymer of tungsten and 5-nitroisophthalic acid is added WO in the reaction kettle 3 (0.0221g), 5-nitroisophthalic acid (0.0428g), 1,10-phenanthroline (0.0199g), KCl (0.0100g), add 5mlH 2 O and lmlCH 3 OH, adjust the pH value of the system with 1ml 0.2M KOH. Stir to ...

Embodiment 2

[0049] In this embodiment, spraying quick-setting rubber asphalt waterproof coating is provided, and the spraying quick-setting rubber asphalt waterproof coating includes:

[0050] 51 parts of natural rubber with cis-1,4-polyisoprene content above 95%, 5.5 parts of three-dimensional coordination polymer of tungsten and 5-nitroisophthalic acid, 7.5 parts of acrylic resin, 4.5 parts of ethylene glycol ether 10.5 parts of petroleum pitch, 1.5 parts of nano-titanium, 1.5 parts of glass microspheres, 2.5 parts of sodium cetearyl sulfate, 3.5 parts of polyacrylamide, 1.5 parts of plasticizer, 2.5 parts of surfactant, 33 parts of water ;

[0051] The three-dimensional coordination polymer of tungsten and 5-nitroisophthalic acid is to add WO3 (0.0221g), 5-nitroisophthalic acid (0.0428g), 1,10-phenanthroline (0.0199 g), KCl (0.0100g), add 5mlH2O and 1mlCH3OH, adjust the pH value of the system with 1ml 0.2M KOH. Stir to make the mixture uniform. After airtight, heat at 150°C for 4 day...

Embodiment 3

[0063] In this embodiment, spraying quick-setting rubber asphalt waterproof coating is provided, and the spraying quick-setting rubber asphalt waterproof coating is made of the following raw materials in parts by weight: the content of cis-1,4-polyisoprene is more than 95% 51 parts of natural rubber, 6 parts of three-dimensional coordination polymer of tungsten and 5-nitroisophthalic acid, 8 parts of acrylic resin, 4 parts of ethylene glycol ether, 10 parts of petroleum pitch, 1 part of nano-titanium, and 1 part of glass microspheres 2 parts, 2 parts of sodium cetearyl sulfate, 3 parts of polyacrylamide, 1 part of plasticizer, 2 parts of surfactant, 30 parts of water;

[0064] The three-dimensional coordination polymer of tungsten and 5-nitroisophthalic acid is added WO in the reaction kettle 3 (0.0221g), 5-nitroisophthalic acid (0.0428g), 1,10-phenanthroline (0.0199g), KCl (0.0100g), add 5mlH 2 O and lmlCH 3 OH, adjust the pH of the system with 1ml 0.2M KOH. Stir to make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap