Gray cast iron piston head ring groove laser cladding repair process

A technology of laser cladding and piston head, applied in metal material coating process, coating and other directions, can solve the problems of irreparable piston head, easy wear of piston ring groove, large impact force of piston ring, etc., to ensure consistent product quality Performance and stability, reliable production quality, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking the laser cladding repair of the piston head of a marine oil extraction machine as an example, a specific implementation method of the laser cladding repair process for the ring groove of the gray cast iron piston head is described. The specific requirements are: no pores, no cracks, hardness > 52HRC, cladding layer thickness > 0.8mm, piston ring groove width 7mm, depth 10mm, the specific steps are:

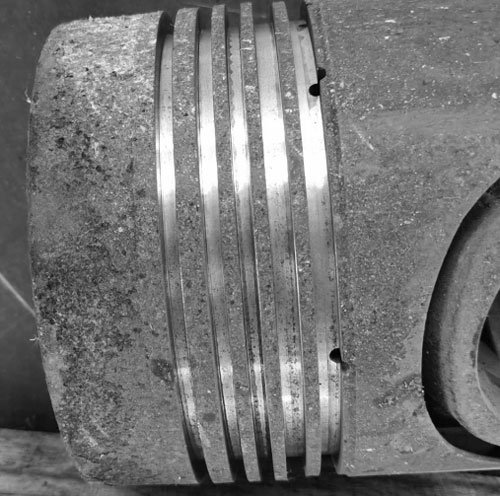

[0026] Step 1: Machining the inner facade of the damaged piston head ring groove that needs to be repaired, turning to remove the fatigue layer and oxide layer, and turning off 0.3mm on both sides of the facade, such as figure 1 shown;

[0027] Step 2: Clean the inner surface of the ring groove, remove burrs and oil stains;

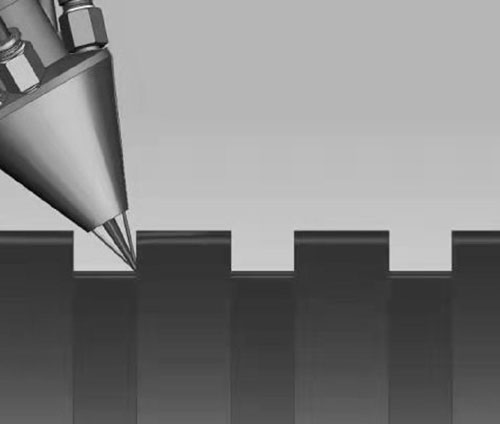

[0028] Step 3: Set the process parameters of the laser cladding equipment to laser clad the iron-based alloy powder on the repaired part of the piston ring groove. During the cladding process, the piston head continues to rotate at a variable ...

Embodiment 2

[0035] The difference between embodiment 2 and embodiment 1 is that in the repair process, the parameters in step 3 are different, specifically:

[0036] The laser cladding uses a 4kW semiconductor laser as the light source, a six-axis robot and a two-axis positioner as the laser cladding motion system, an airborne powder feeder as the powder feeding mechanism, and a three-way coaxial powder feeding cladding head as the The laser head, as a whole, constitutes a laser cladding system for continuous scanning of laser cladding. The process parameters of the laser cladding are as follows: the size of the laser focus spot is φ1.8mm, and the powder feeding nozzle of the cladding head is three-way coaxial feeding. The powder nozzle has a working distance of 35mm, an inclination angle of 45°, and an output power of 1600W. The piston head is continuously rotated by the positioner to ensure a uniform cladding line speed of 11mm / s. The cladding layer is overlapped from the inside to the o...

Embodiment 3

[0038] The difference between embodiment 3 and embodiments 1 and 2 is that in the repair process, the parameters in step 3 are different, specifically:

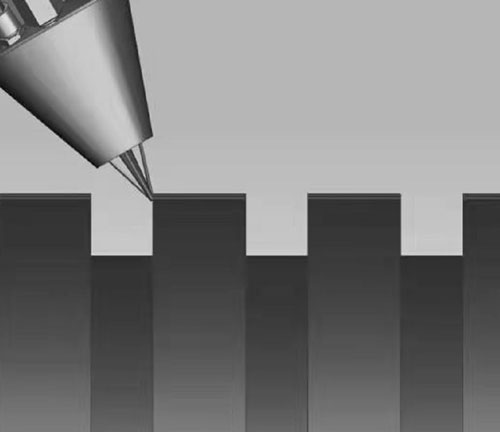

[0039]The laser cladding uses a 4kW semiconductor laser as the light source, a six-axis robot and a two-axis positioner as the laser cladding motion system, an airborne powder feeder as the powder feeding mechanism, and a three-way coaxial powder feeding cladding head as the The laser head, as a whole, constitutes a laser cladding system for continuous scanning of laser cladding. The process parameters of the laser cladding are as follows: the size of the laser focus spot is φ1.8mm, and the powder feeding nozzle of the cladding head is three-way coaxial feeding. The powder nozzle has a working distance of 35mm, an inclination angle of 60°, and an output power of 2000W. The piston head is continuously rotated by the positioner to ensure a uniform cladding line speed of 12mm / s. The cladding layer is overlapped from the inside to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com