Large-scale continuous manufacturing device for flexible ceramic nanofibers

A nanofiber and manufacturing device technology, which is applied in the field of flexible ceramic nanofiber large-scale continuous manufacturing devices, can solve problems such as difficulty in realizing ceramic nanofiber large-scale production line manufacturing, limiting the application of ceramic nanofibers, and organic matter removal process pollution, etc. The effect of ensuring continuity and stability, ensuring safe continuous production, and facilitating subsequent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

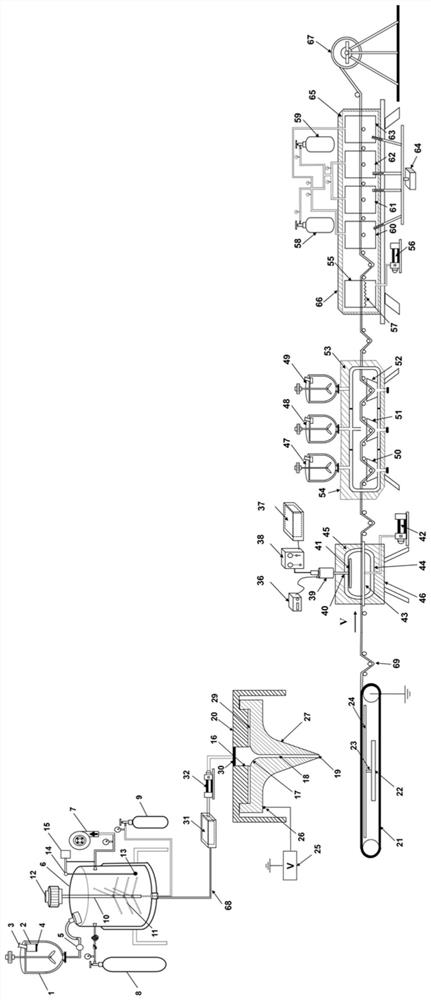

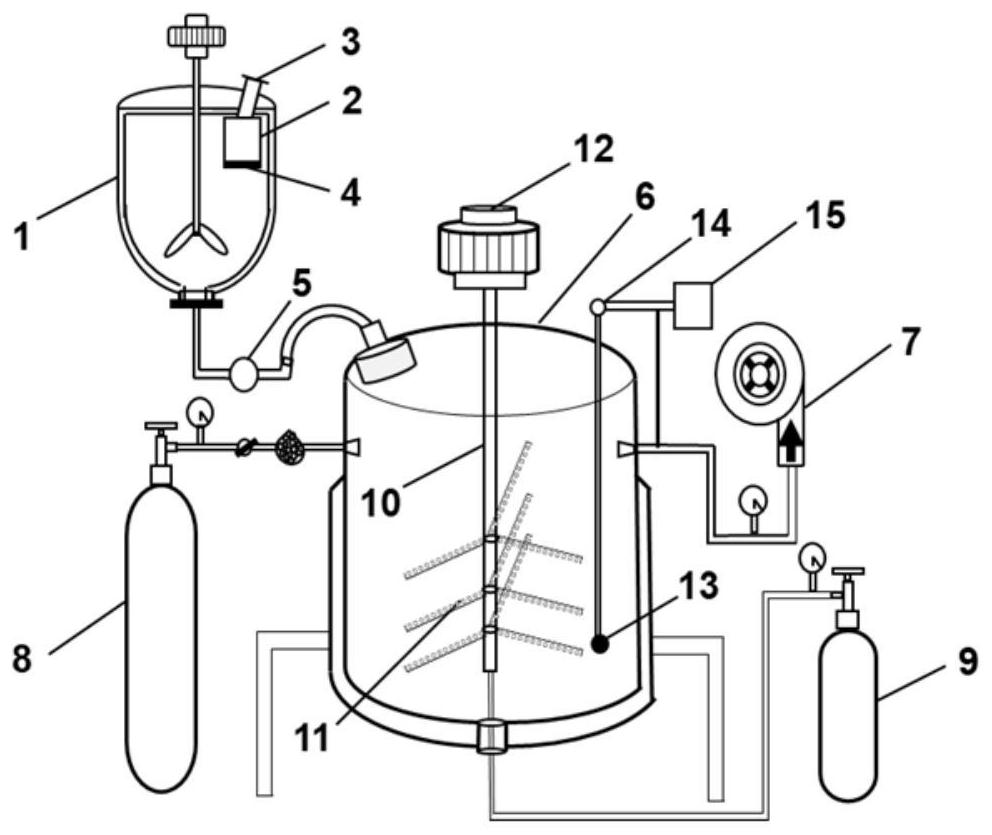

[0105] In order to achieve large-scale and stable preparation of ceramic nanofibers with excellent performance, this embodiment provides a large-scale continuous manufacturing device for flexible ceramic nanofibers, please refer to Figure 1 to Figure 15 As shown, its structure includes:

[0106] Sol spinning solution preparation mechanism;

[0107] Electrospinning mechanism: including a first liquid storage tank 31 connected to the outlet of the spinning solution of the sol spinning solution preparation mechanism, and an electrospinning nozzle connected to the first liquid storage tank 31 and used for outputting spun fibers;

[0108] Fiber calcining and forming mechanism: including analytical components, solvent gradient replacement components, drying components and variable atmosphere calcination components arranged in sequence along the direction of spinning fiber processing, in addition, behind the variable atmosphere calcination components, there is also a ceramic for win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com